26

S03

FLUIDS

WATER QUALITY FOR MIXING WITH COOL-

ANT CONCENTRATE

Engine coolants are a combination of three chemical

components: ethylene glycol (EG) or propylene glycol (PG)

antifreeze, inhibiting coolant additives, and quality water.

Water quality is important to the performance of the

cooling system. Deionized or demineralized water is

recommended for mixing with ethylene glycol and

propylene glycol base engine coolant concentrate.

All water used in the cooling system should meet the

following minimum specifications for quality:

Chlorides

<40 mg/L

Sulfates

<100 mg/L

Total solids

<340 mg/L

Total dissolved I hardness

<170 mg/L

pH

5.5—9.0

IMPORTANT!

Do not use bottled drinking water because it often con-

tains higher concentrations of total dissolved solids.

Freeze Protection

The relative concentrations of glycol and water in the en

-

gine coolant determine its freeze protection limit.

Ethylene Glycol

Freeze Protection Limit

40%

-24°C (-12°F)

50%

-37°C (-34°F)

60%

-52°C (-62°F)

Propylene Glycol

Freeze Protection Limit

40%

-21°C (-6°F)

50%

-33°C (-27°F)

60%

-49°C (-56°F)

DO NOT use a coolant-water mixture greater than 60%

ethylene glycol or 60% propylene glycol.

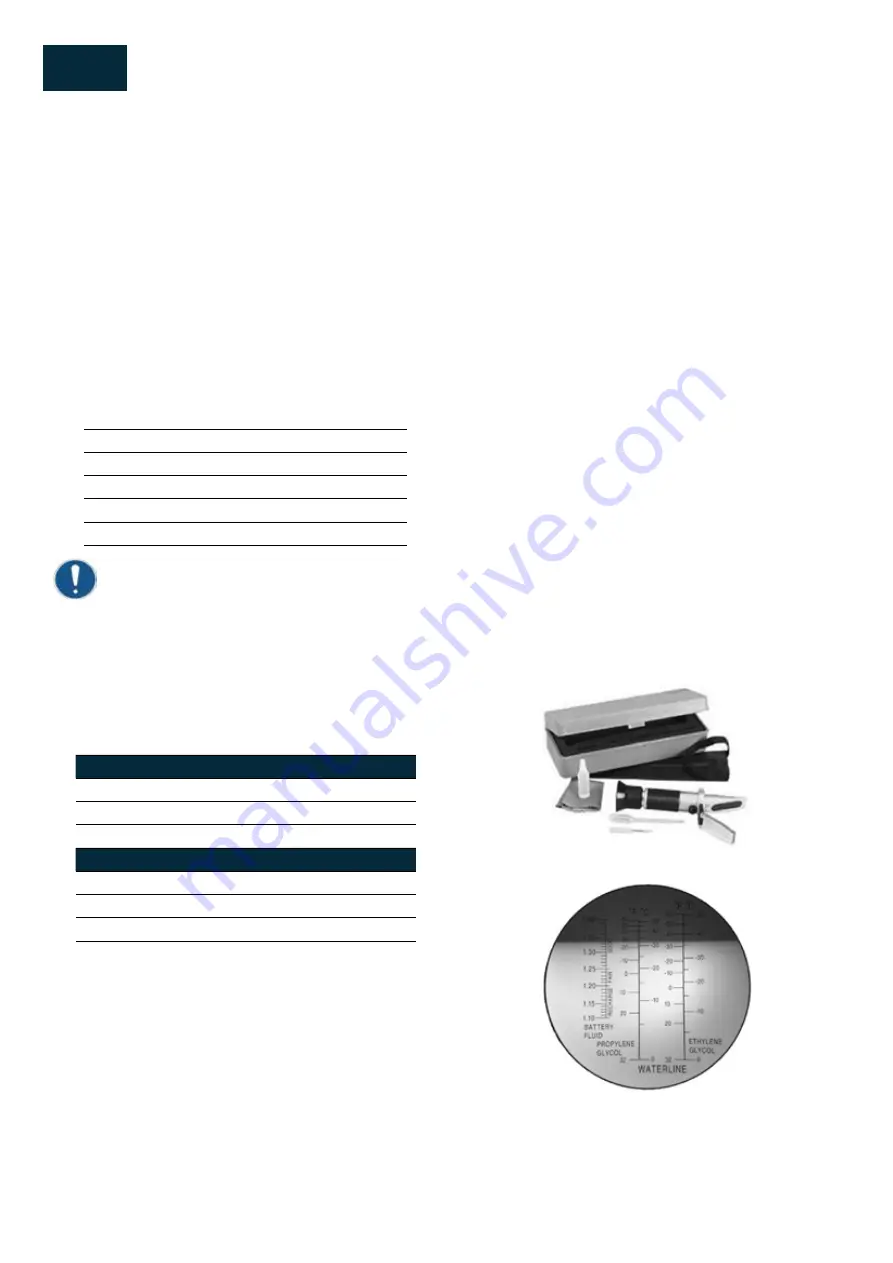

TESTING COOLANT FREEZE POINT

The use of a hand-held coolant refractometer is the

quickest, easiest, and most accurate method to determine

coolant freeze point. This method is more accurate than

a test strip or a float-type hydrometer which can produce

poor results.

A coolant refractometer can be used to provides an eco-

nomical solution to accurate freeze point determination

in the field.

To use this tool:

1.

Allow cooling system to cool to ambient tempera-

tures.

2.

Open heat-exchanger cap to expose coolant.

3.

With the included dropper, collect a small coolant

sample.

4. Open the lid of the refractometer, place one drop of

coolant on the window and close the lid.

5. Look through the eyepiece and focus as necessary.

6.

Record the listed freeze point for the type of coolant

(ethylene glycol coolant or propylene glycol) being

tested.

Part Number 945400245

Image with a Drop of 50/50 Coolant

Placed on the Refractometer Window

Summary of Contents for Q1500 Series

Page 1: ...NANNI GENERATOR SET USER MANUAL DGBXXT090049 Q1500 Series...

Page 2: ......

Page 4: ...4 Q00 TRACKED CHANGES...

Page 8: ...8 S00 SUMMARY...

Page 32: ...32 S03 FLUIDS...

Page 38: ...30 S05 COMPOSANTS...

Page 40: ...32 S05 COMPOSANTS VIEW N 1 OF THE GENERATOR SET...

Page 41: ...33 S05 COMPOSANTS VIEW N 2 OF THE GENERATOR SET...

Page 52: ...52 S 07 MAINTENANCE Battery voltage 72 Battery specific gravity 72...

Page 53: ...53 S 07 MAINTENANCE...

Page 74: ...74 S 07 MAINTENANCE...

Page 76: ...76 S08 AL TERNATOR...

Page 88: ......

Page 96: ...96 S11 TROUBLE SHOOTING...

Page 97: ......

Page 98: ......