Page 5

17-110-0143

3. Product Description

3.1 Technical Specification

The nitrogen generator operates on the Pressure Swing Adsorption (PSA) principle to produce a continuous

stream of nitrogen gas from clean dry compressed air.

Pairs of dual chamber extruded aluminium columns, filled with Carbon Molecular Sieve (CMS), are joined via

an upper and lower manifold to produce a two bed system. Compressed air enters the bottom of the ‘online’

bed and flows up through the CMS. Oxygen is preferentially adsorbed by the CMS, allowing nitrogen to pass

through.

After a pre-set time the control system automatically switches the bed to equalization mode where the online

bed pressure is equalized with the second regenerated bed. Once equalized the online bed is switched to

regenerative mode and oxygen is vented from the CMS. A small portion of the outlet nitrogen gas is expanded

into the bed to accelerate the regeneration. At the same instant the second bed comes on-line and takes over

the separation process.

The CMS beds alternate between online equalization and regeneration modes to ensure continuous and

uninterrupted nitrogen production.

When a generator is specified with an internal dryer, each CMS column has a unique adsorption media tube

technology dryer fitted into the bottom of each column.

The unique intergrated dryer does not require servicing and the life is aligned to the CMS material.

The intergrated dryer reduces energy running costs by eliminating the additional external dryer purge (typically

20% of the dryer inlet air consumption) and the associated pressure loss across an external dryer. The

compressed air requirement is also reduced accordingly.

The oxygen concentration in the nitrogen stream is monitored continuously on models fitted with an oxygen

analyzer. If the outlet concentration exceeds the required production level, the nitrogen outlet is closed and the

gas is vented to atmosphere. Normal operation will resume when the purity recovers.

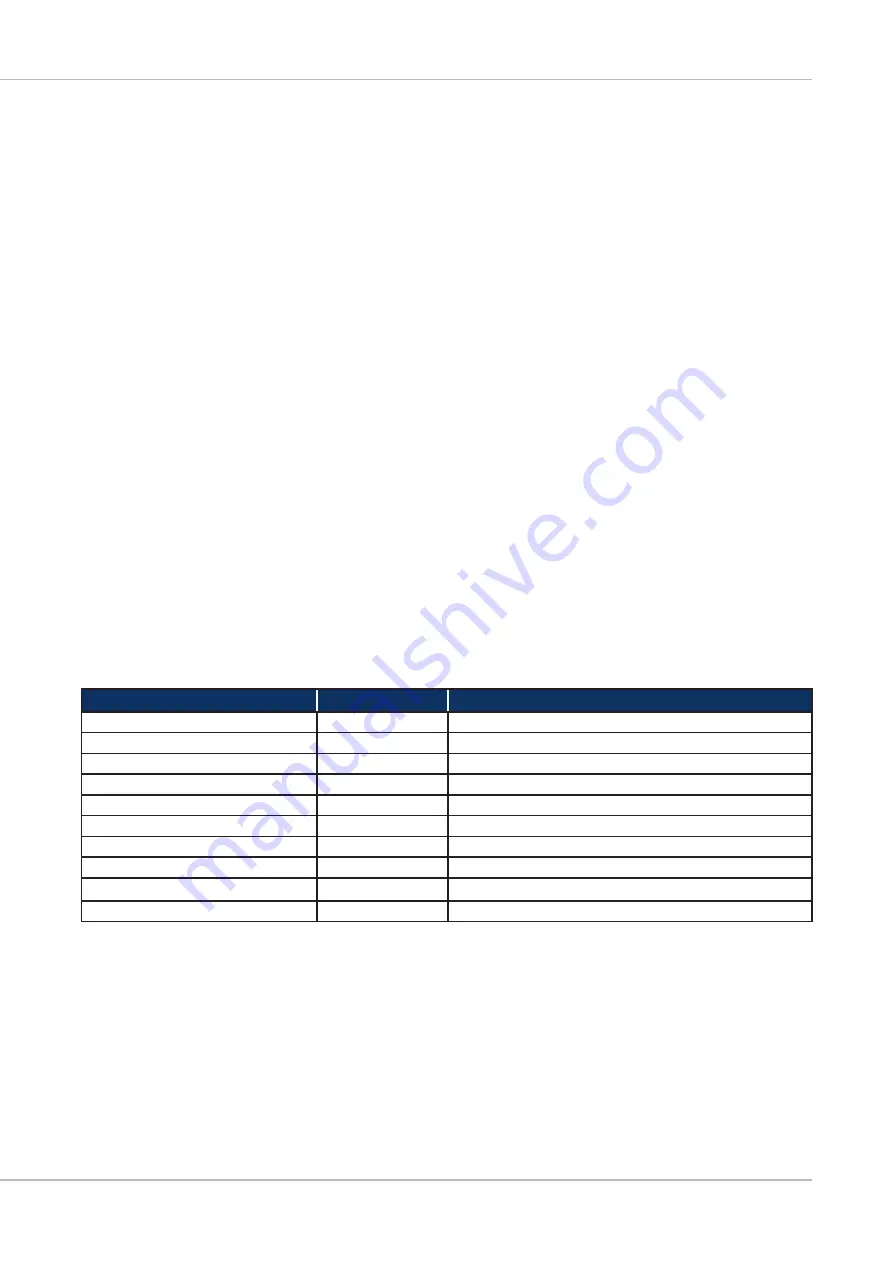

Parameter

Units

Inlet Air Quality

ISO 8573.1:2010

Class 1.2.1 / Class 1.5.1 (when fitted with AMT integral dryer)

Minimum Inlet Pressure

Barg (psig)

6 (88)

Maximum Inlet Pressure

Barg (psig)

10 (145) or 16 (232)

Rated Inlet Temperature

°C (°F)

20-25 (68-77)

Minimum Inlet Temperature

°C (°F)

5 (41) - Subject to correction factor.

Maximum Inlet Temperature

°C (°F)

40 (104) - Subject to correction factor.

Supply Voltage

VAC (50/60Hz)

88-264 VAC

Input Current

Amps (VAC)

1.3 / 0.8 (110-230)

IP Rating

IP11 / NEMA 2

Noise

dB (A)

<90

Summary of Contents for GEN2-1110

Page 1: ...GEN2 NITROGEN GENERATOR USER GUIDE...

Page 26: ...Page 26 17 110 0143 Notes...

Page 27: ...Page 27 17 110 0143 Notes...