1. SPECIFICATION

MODEL

WORKING STEAM

PRESSURE

STEAM VALVE

WEIGHT

BASE-PLATE SIZE

BODY TREATMENT

HSP-140

0.1 — 0.5 MPa

(1 — 5 bar)

PUSH LEVER TYPE

1.1 kg

203mm X 99mm

“TUFRAM”

2. ATTACHMENT & ACCESSORIES

The following attachments and accessories

are packaged in the same carton as the Iron.

1. 1 pc. Silicone Iron Rest

2. 1 pc. Mesh Filter

3. 2 pc. Packing

4. 1 pc. Inner Tube

5. 1 pc. O- Ring (P- 4)

6. 1 pc. O- Ring Stopper

7. 1 pc. Joint Spring

8. 1 pc. Instruction Manual (This booklet)

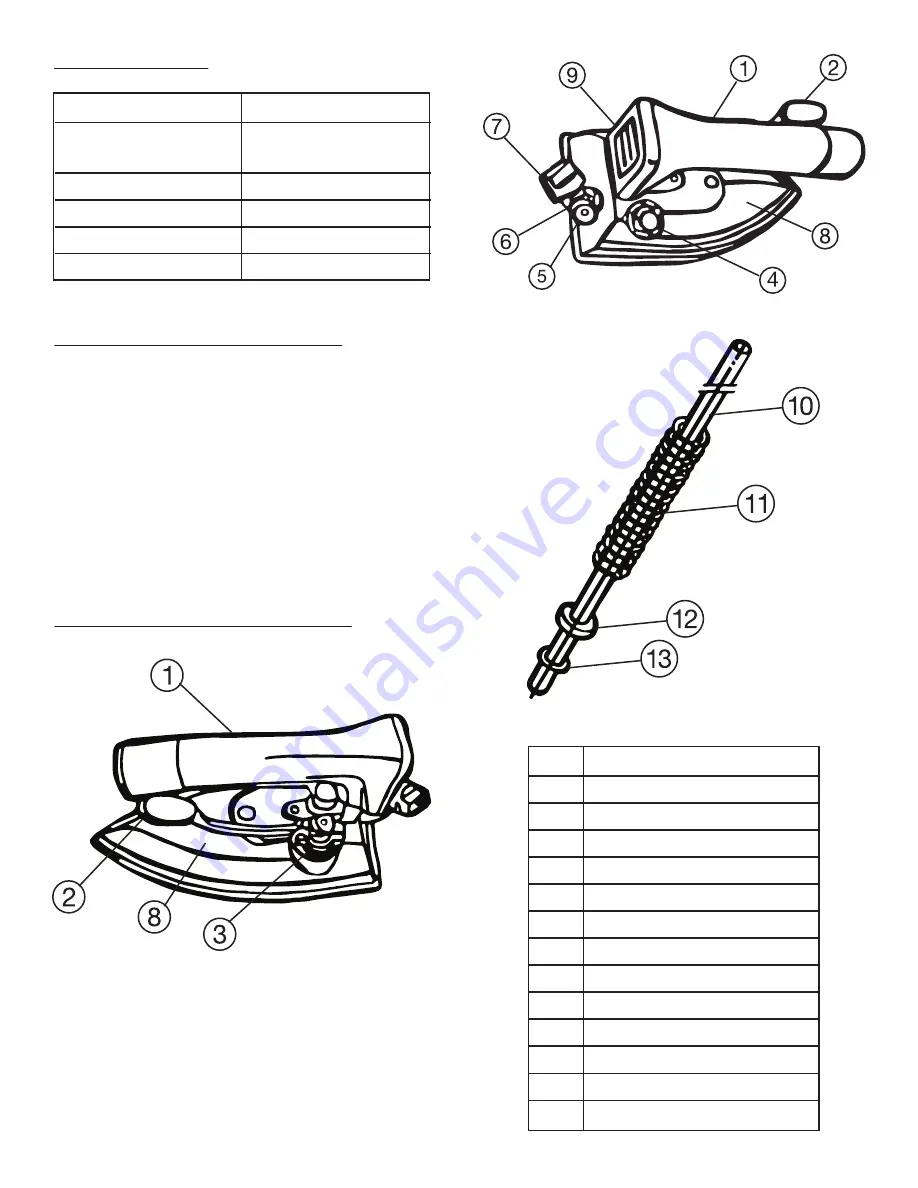

3. NAMES OF COMPONENT PARTS

No.

Name

1

Urethane Grip Handle

2

Push Lever

3

Steam Valve

4

Steam Supply Hose Joint

5

Drain Hose Joint

6

Drain Valve

7

Knob of Drain Valve

8

Plastic Full Cover

9

Name Plate

10

Inner Tube (Ø 3-Ø 4 Dia)

11 Hose Joint Spring

12

O-Ring Stopper

13

O-Ring (P-4)