Inside Cross

Section

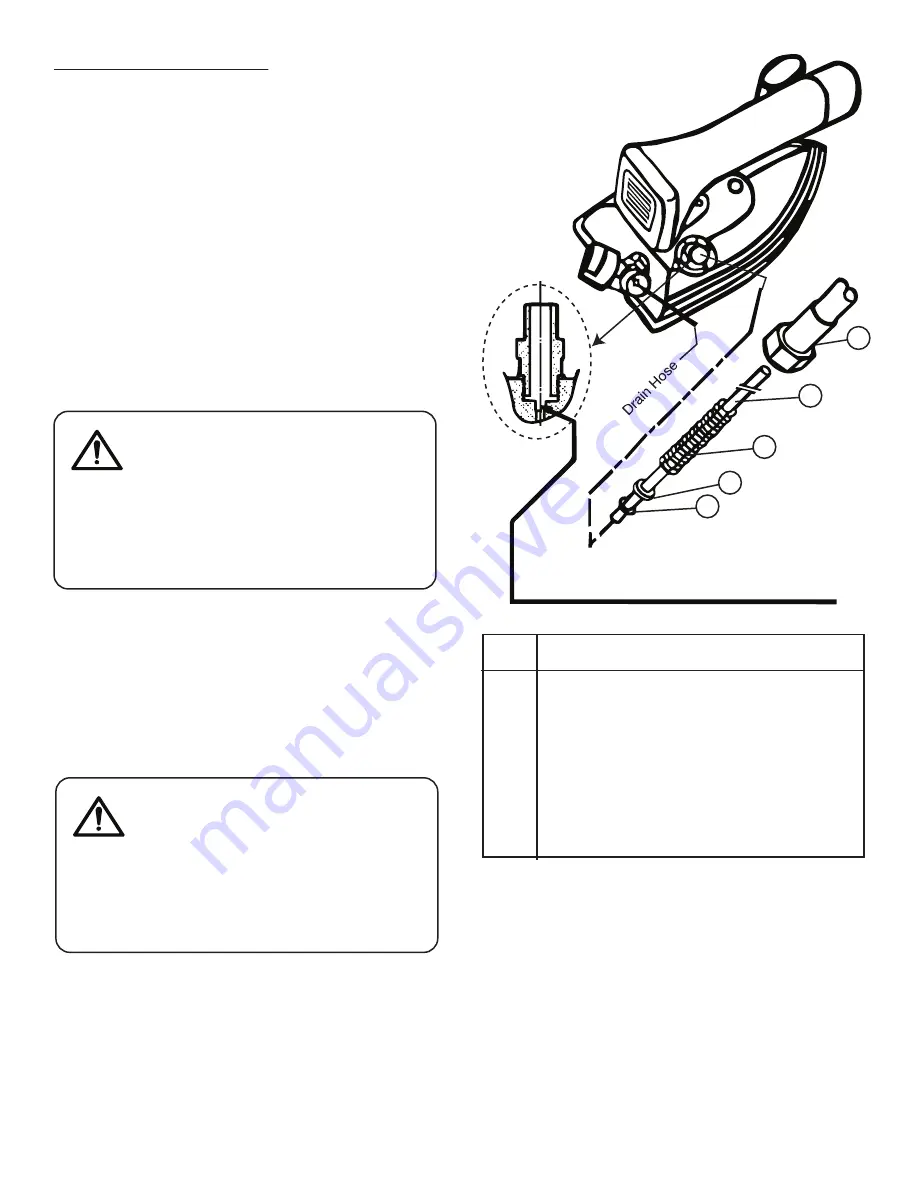

Insert tip of the Teflon - Hose into this hole.

5. INSTALL & ASSEMBLE

When setting up the iron, be sure also to

read carefully instruction manuals of related

equipment such as the boiler and ironing

table beforehand

5.1 Set Up of Hoses

- 2 (two) hoses for steam-supply and drain are

required for this iron. Please purchase each

exclusive hose.

If the Inner-Tube is needed to avoid drain

water. It is necessary for minor diameter of

internal of the steam-supply hose to be more

than 5mm at the narrowest part (mouthpiece

part).

5.2 Installation of Hoses

CAUTION

Please do not use any other steam

supply hose than the Naomoto Extra-

Hose especially for steam pressure that

does not exceed 0.3 MPa (3 bar). Naoflon hose

should be used for the drain hose. Use of a non-

genuine hose of which proof pressure is not

confirmed may cause malfunction.

Before setting the Special Extra-Hose to the

iron, clean the inside of the hose by washing

out any dust and dirst. To do this, first fix the

Special Extra-Hose to the boiler, then open

the boiler’s steam valve, and steam flow will

wash out dust and dirt.

CAUTION

While the above cleaning work is being

carried out, place a receptacle (like the

NAOMOTO cartridge-type water tank at

the open end of the Extra Hose to catch the flow

of steam gushing out. Do not touch the Hose with

bare hands as it can be extremely hot. In addition,

take care not to get scalded by the gushing steam

No.

Name

1

NAOFLON EXTRA HOSE

2

Inner Tube

(Teflon Hose with Dia. 3-4 mm.)

(Lengthen hose more for more drain water)

3

Hose Joint Spring

4

O-ring Stopper

5

Silicone O-ring (P-4)

When water drops do not come out of the iron

while steaming, above inner tube is not

necessary.

- Installation of the Steam Supply Hose

Insert the inner tube(2) into the hose joint

spring(3), the O-ring stopper(4) and the

O-ring(5), then insert the tube-tip into the

back hole in the steam supply hose joint

of the iron.

1

2

3

4

5