7. MAINTENANCE & CHECKING

In case any problems occur with the iron or the boiler, contact the nearest NAOMOTO office or agent

from whom you purchased the equipment.

In order to ensure your equipment is trouble-free, it is important to operate it correctly and also to

keep up regular maintenance checks. Please observe the following procedures.

7.1 Daily Maintenance & Checking

- Clean the iron by removing dust and adhered starch-residues.

- Empty completely remaining steam and condensate in the iron and the hose.

- Check and confirm that there is no steam leakage at the base-plate and the valve while the

swing-lever is in normal posiyion (i.e. the valve is closed).

7.1 Troublehooting

- If you have any problems with the equipment, please check the symptoms and take necessary

countermeasures outlined below where applicable.

- If you need to replace any parts, ask the nearest NAOMOTO office or its agent for the replacement

parts.

WARNING

Before making any checks or carrying out any maintenance work on the iron, be sure to cut the steam

source and empty out any steam from the iron and the steam hose, then wait until the iron cools down.

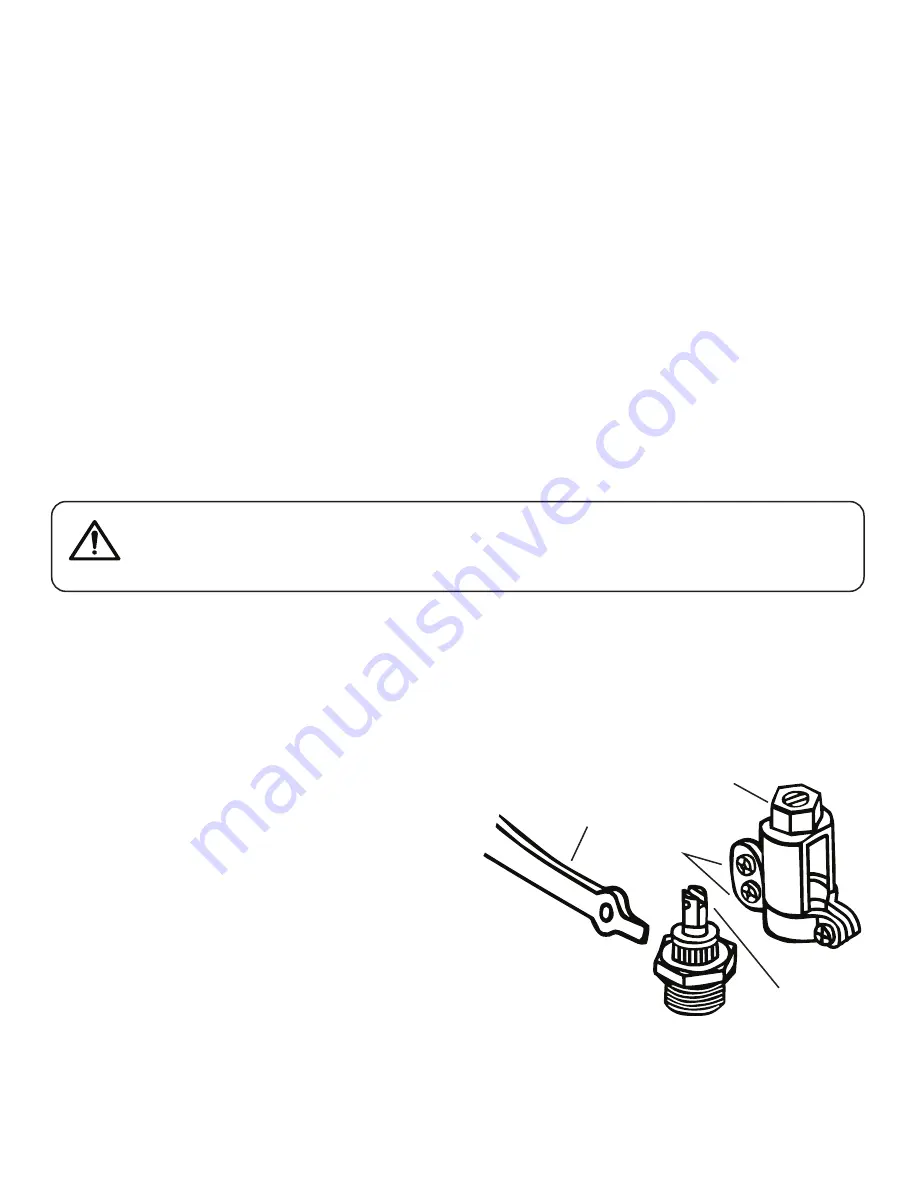

- Inconsistent Steam Flow

- In case steam valve cannot be closed enough

to stop the steam flow, replace the valve

spindle with a new one.

- Also, ascertain that there is no dust or flaw

with each packing, valve seat, O-ring, washer

etc. In case any part is found damaged,

replace it with a new one.

- Disassemble the valve.

- Insert a wire of dia 1.5mm into the valve

spindle while pushing the lever.

- Unscrew 3 stopping screws of the lever, then

remove push lever and metal fitting.

Push Lever

Adjuster Screw

Set Screw

Set Screw

Valve Spindle