6-701A

5

Rev. 09/09/19

PLEASE REVIEW ALL WARNING INSTRUCTIONS PRIOR TO OPERATION. SAVE THIS MAN U AL FOR FUTURE REF ER ENCE.

Always turn off the air supply, drain

hose of air pressure and detach tool

from air supply before installing,

removing or adjusting any part or

accessory on this tool, or before per-

forming any maintenance on this tool.

The position of the shearing head

can be changed by loosening the

allen head screw shown in fig. 1.

1. Detach from air supply.

2. Then turn cutter housing to desired

position and tighten allen head

screw securely. NEVER use this air

shear on material with a gauge

greater than 18 as this will result in

breakage of the center blade.

Cutting with this tool will create

sharp edges. Wear gloves to

protect hands.

Cutting edges and shear blades

can become hot during use. Do

not touch.

Never force the tool to cut faster

or through heavier gauge material

than rated capacity.

NOTE: During operation, safety goggles

should always be worn to guard against

flying debris (users and bystanders).

OPERATION

Specifications

Overall Length .............................. 10"

Width ......................................... 2.36"

Weight .................................... 2.2 lbs.

RPM .................................. 2,600 SPM

Max. material thickness

metal sheet ............18 gauge (1.2mm)

Sound Level ............................ 80dBa

Vibration Level .......................1.6m/s2

Air Consumption ................... 3.1CFM

Air Inlet Thread Size .......1/4"-18 NPT

Recommended Hose Size ....3/8" I.D.

Recommended

Air Pressure .................90psi (6.2 bar)

WARRANTY

Important: DO NOT RETURN DEFECTIVE PRODUCT OUTSIDE OF ORIGINAL ONE (1) YEAR WARRANTY PERIOD TO

PLACE OF PURCHASE.

WARRANTY POLICY:

This Carlyle Air Tool is warranted against defects in material and workmanship for a period of One (1) Year

from the date of original purchase. We will replace, at our option, any part which proves to be defective in material or workman-

ship. Repairs or replacements are warranted as described above for the duration of the original warranty period. In the unlikely

event a replacement unit is required during this One (1) year period, return the unit to your local NAPA Auto Parts Store for a

replacement. This warranty does not apply to products which have been subjected to abuse, misuse, modification, neglect, lack of

maintenance, use in a production-related service, or repaired by anyone other than an Authorized Carlyle Air Tool Service Center.

For complete listing of Authorized Master Repair Centers, see enclosed Customer Warranty Repair Form, or

visit www.toolwarrantyrepair.com

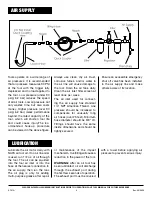

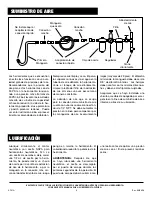

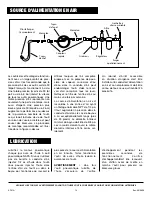

fig. 1.

Air Inlet