W415-0973 / B / 08.28.13

39

IOM

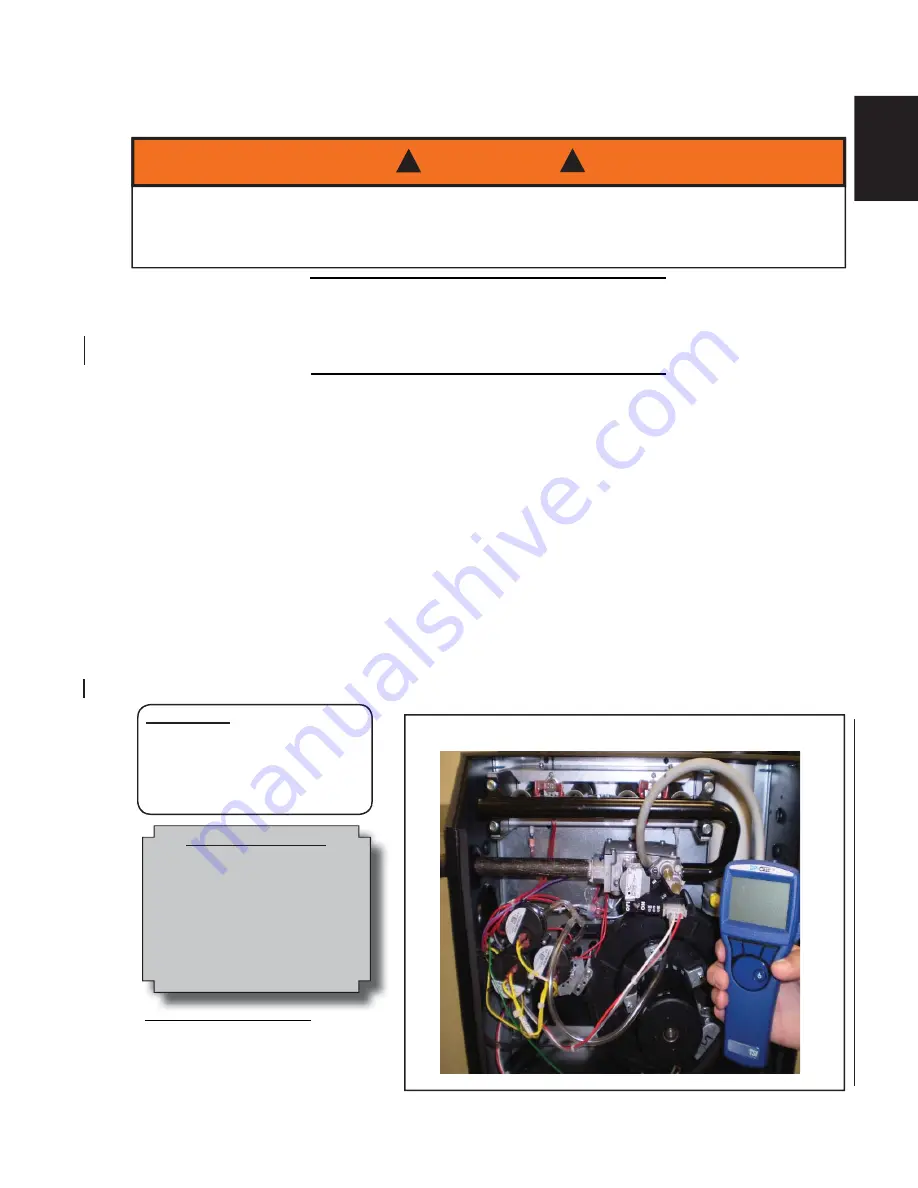

13.5 CHECKING FURNACE INPUT

FIGURE 30 - MANOMETER MEASURING GAS MANIFOLD PRESSURE

6.

Remove the manometer hose from the outlet pressure tap boss, and tighten the outlet pressure tap screw

using the 3/32” Allen wrench. (Clockwise, 7 in-lb minimum).

H3.21

ALL REGULATOR ADJUSTMENTS MUST BE DONE BY A TRAINED, QUALIFIED

TECHNICIAN. IMPROPER MODIFICATIONS OR ADJUSTMENTS CAN RESULT IN FIRE OR

EXPLOSION CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR LOSS OF

LIFE.

WARNING

!

!

H18.5.1

7. Turn on the gas supply and electrical power to the furnace.

8. Turn on system power and energize valve.

9. Using a leak detection solution, check for leaks at pressure boss screw. Bubbles forming indicate a leak.

SHUT OFF GAS AND FIX ALL LEAKS IMMEDIATELY!

H18.6.1

The natural gas supply pressure should be a maximum of 7” w.c. and minimum of 5” w.c. The burner manifold

pressure is factory set to 3.5” w.c. The input rating of the furnace is based on 1000 Btu/ft.³ gas with a speci

fi

c

gravity of 0.6.

Since heating values for the gas vary geographically, the actual furnace input and output will vary accordingly.

For example, natural gas with a 900 Btu/ft.³ heating value will reduce the input to 90% of the rated input.

Natural gas with a 1100 Btu/ft.³ heating value will increase the input to approximately 110% of the rated input.

This is not usually a problem; however, adjustments to compensate for this can be made by minor adjustments

to the burner manifold pressure or by changing the burner ori

fi

ce size. Contact the fuel supplier for speci

fi

c

heating content values.

Any adjustments to the burner manifold pressure should be carried out with the use of a manometer or

calibrated Magnehelic® gauge. Do not adjust the gas valve pressure regulator more than ±0.3” w.c. Refer to

Setting The Manifold Gas Pressure and Figure 30.

IMPORTANT:

NEVER ADJUST THE INPUT

OF THE FURNACE TO

EXCEED THE INPUT SHOWN

ON THE RATING PLATE.

Input =

Heating Value of Gas x 3600

Time in Sec. for 1 cu. ft.

where:

•

input is expressed in Btu/hr

•

heating value of the gas is expressed in Btu/ft

3

• and time is the number of seconds required for

the test dial to indicate 1 cubic foot.

If using a gas meter with SI (metric) units:

•

1 cubic foot = 0.0283 cubic meters

•

1 cubic meter = 35.315 cubic feet

•

0.01 cubic meter = 0.3531 cubic feet

•

0.5 cubic meter = 1.766 cubic feet

Summary of Contents for 9500 series

Page 25: ...W415 0973 B 08 28 13 25 IOM FIGURE 14A DIRECT VENT TERMINAL CLEARANCES...

Page 26: ...W415 0973 B 08 28 13 26 IOM IOM FIGURE 14B NON DIRECT VENT TERMINAL CLEARANCES...

Page 55: ...W415 0973 B 08 28 13 55 IOM 23 0 SERVICE HISTORY 43 1...

Page 56: ...W415 0973 B 08 28 13 56 IOM IOM 44 1 24 0 NOTES...