W415-2159 / D / 11.24.17

37

IOM

12.3 GAS INLET PRESSURE

12.4 LEAK TESTING

12.5 PURGING GAS LINES

H17.2B

IMPORTANT:

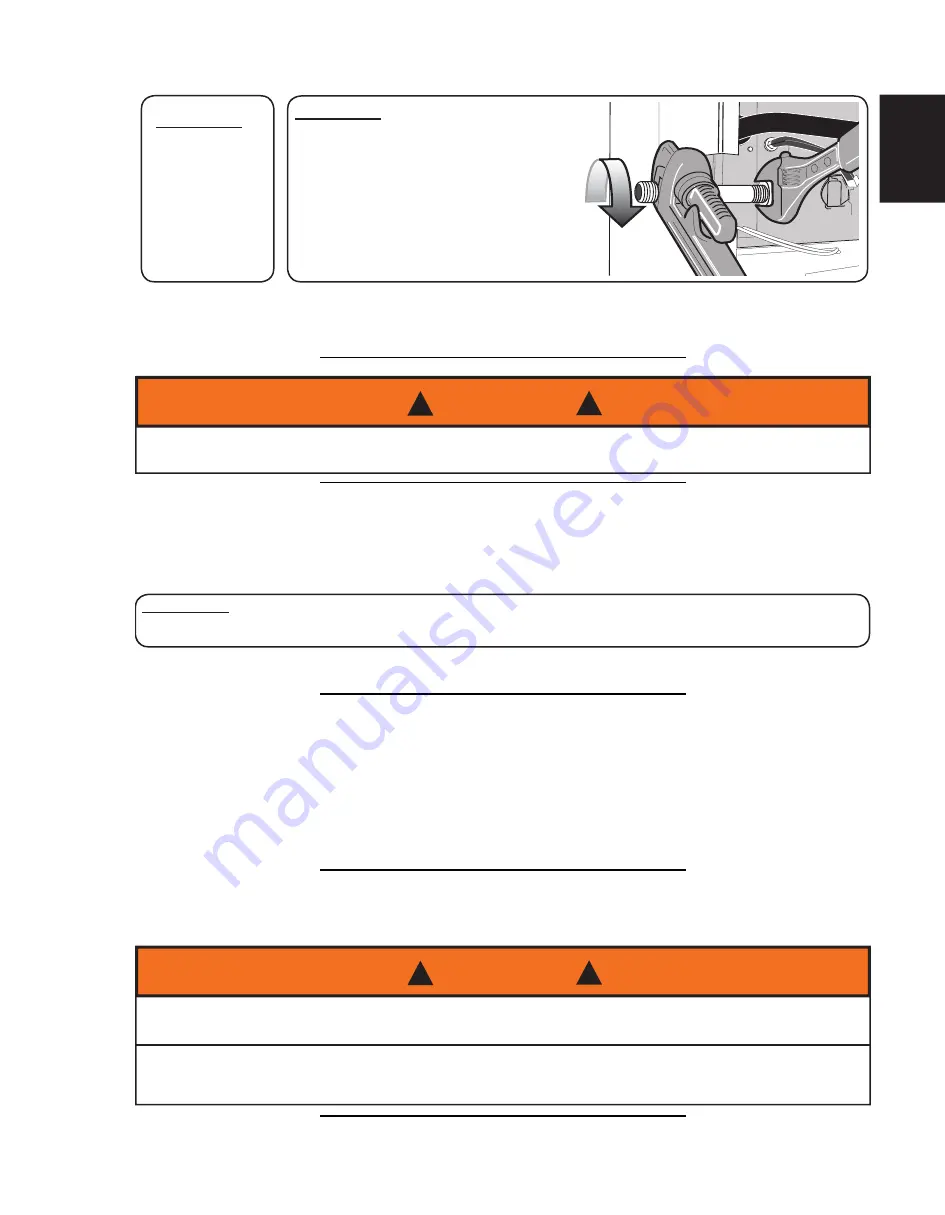

ALWAYS USE A BACKUP

WRENCH TO PREVENT TWISTING

OF THE GAS VALVE. ANY

STRAINS ON THE GAS VALVE

CAN AFFECT POSITIONING OF

THE ORIFICES RELATIVE TO THE

BURNERS. THIS COULD RESULT

IN FAULTY BURNER OPERATION.

Install a manual gas shut-off valve and dirt pocket as close to the furnace as possible. Some local codes call

for the manual gas shut-off valve to be located between 4 feet (1.2m) to 5 feet (1.5m) above

fl

oor level to

prevent tampering by small children. Ensure that the valve is readily accessible.

IMPORTANT:

ENSURE

THAT THE

GAS VALVE

IS NOT

SUBJECTED

TO HIGH

PRESSURES.

H3.19

DISCONNECT THE MANUAL SHUT-OFF VALVE AND GAS VALVE DURING ANY

PRESSURE TESTING THAT EXCEEDS 1/2 P.S.I.G. (3.45 KPA).

WARNING

!

!

H17.3.3A

The natural gas inlet supply pressure should be 5” to 7” w.c. (7” w.c. recommended). These pressures must be

maintained while all other gas

fi

red appliances are operating at maximum conditions.

IMPORTANT:

DO NOT EXCEED 13” W.C. INLET PRESSURE.

The gas valve has two adjustable internal regulator for controlling burner manifold pressure. Burner manifold

high

fi

re and low

fi

re pressures are listed on the furnace rating plate.

H17.4

All new gas piping installations should be pressure tested as speci

fi

ed by CAN/CSA-B149.1 & 2, or NFPA 54

ANSI Z223.1 or ANSI/NFPA 58,

“Standard for the Storage and Handling of Liquefi ed Petroleum Gases.”

Gas piping that has not been pressure tested, from the manual shut-off valve to the furnace gas valve for

example, should be leak tested using an electronic combustible gas detector, a commercially prepared leak

detector, or other locally approved method.

H3.20

NEVER USE A MATCH, TAPER, CIGARETTE LIGHTER, FLAME OR ANY OTHER IGNITION

SOURCE TO CHECK FOR LEAKS IN A GAS LINE.

FAILURE TO ADHERE TO THIS WARNING CAN CAUSE A FIRE OR EXPLOSION

RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE.

WARNING

!

!

Summary of Contents for 9600E E-STAR Series

Page 27: ...W415 2159 D 11 24 17 27 IOM FIGURE 14A DIRECT VENT TERMINAL CLEARANCES...

Page 28: ...W415 2159 D 11 24 17 28 IOM IOM FIGURE 14B NON DIRECT VENT TERMINAL CLEARANCES...

Page 57: ...W415 2159 D 11 24 17 57 IOM 23 0 SERVICE HISTORY 43 1...

Page 58: ...W415 2159 D 11 24 17 58 IOM IOM 24 0 NOTES 44 1...

Page 74: ...6 0 NOTES 44 1 W415 2159 D 11 24 17 UM 74...