W415-1326 / 05.23.14

20

EN

28.5A

A.

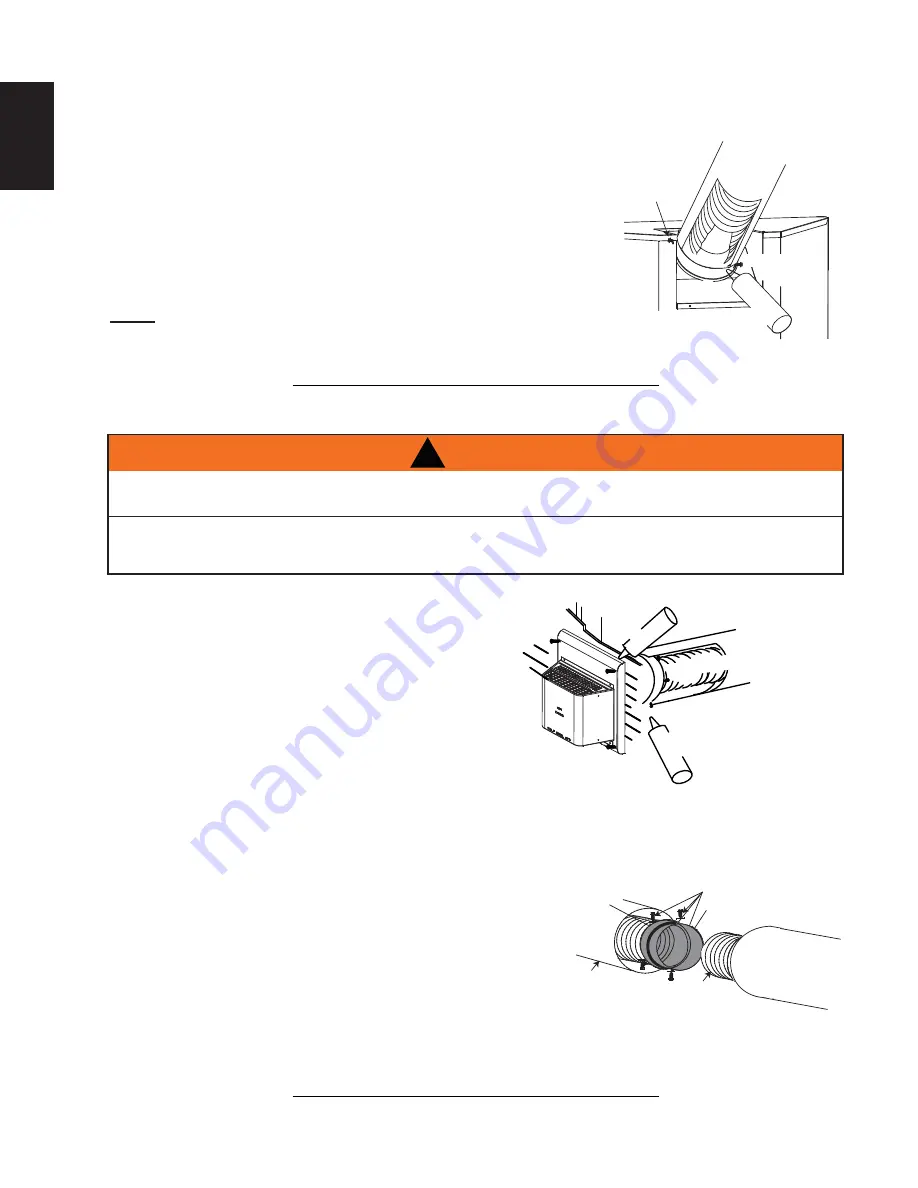

Attach the adjustable pipe to the last section of rigid pipe. Secure

with screws and seal.

B.

Install the inner

fl

ex pipe to the appliance. Secure with 3 screws

and

fl

at washers. Seal the joint and screw holes using the high

temperature sealant W573-0007 (not supplied).

C.

Run a bead of high temperature sealant (not supplied) around the

inside of the air intake collar. Pull the adjustable pipe a minimum 2”

(50.8mm) into the air intake collar.

NOTE: Ensure that the sealant is not visible on the exterior pipes once

installation is completed. An optional decorative black band is available

for this use. In the event that the venting must be disassembled, care

must be taken to reseal the venting.

#8 X 1/2”

SELF

DRILLING

SCREWS

HIGH TEMPERATURE

SEALANT

2” (50.8mm)

OVERLAP

TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE

RETURN FLANGE OF THE MOUNTING PLATE.

DO NOT ALLOW THE INNER FLEX PIPE TO BUNCH UP ON HORIZONTAL OR VERTICAL RUNS AND

ELBOWS. KEEP IT PULLED TIGHT.

!

WARNING

A.

Stretch the inner

fl

ex pipe to the required length

taking into account the additional length needed for

the

fi

nished wall surface. Apply a heavy bead of the

high temperature sealant W573-0007 Mill Pac (not

supplied) to the inner sleeve of the air terminal. Slip

the vent pipe a minimum of 2” (50.8mm) over the inner

sleeve of the air terminal and secure with 3 #8 screws.

`

B.

Using the outer rigid pipe, slide over the outer combustion air

sleeve of the air terminal and secure with 3 #8 screws. Seal

using high temperature sealant W573-0002 (not supplied).

C.

Insert the vent pipes through the

fi

restop maintaining the required clearance to combustibles. Holding the air

terminal (lettering in an upright, readable position), secure to the exterior wall and make weather tight by sealing

with caulking (not supplied).

D.

From inside the house, using silicone, seal between the vent

pipe and the

fi

restop. Then slide the black trim collar over the

vent pipe up to the

fi

restop.

E.

If more vent pipe needs to be used to reach the appliance,

couple them together as illustrated. The vent system must

be supported approximately every 3 feet (0.9m) for both

vertical and horizontal runs. Use noncombustible strapping

to maintain the minimum clearance to combustibles.

The air terminal mounting plate may be recessed into the exterior wall or siding no greater than the depth of its

return fl ange.

23.7C

SCREWS

#10x2"

SEALANT

HIGH TEMP

2" (50.8mm) OVERLAP

CAULKING

7" (177.8mm) RIGID

PIPE

4" (101.6mm) FLEX PIPE

#8 X 1/2”SELF DRILLING

SCREWS & WASHERS

INNER COUPLER

HI-TEMP

SEALANT

OUTER

RIGID PIPE

INNER

FLEX PIPE

OUTER

RIGID PIPE

4.2 APPLIANCE VENT CONNECTION

4.3 HORIZONTAL AIR TERMINAL INSTALLATION