32

W415-0763 / B / 10.28.11

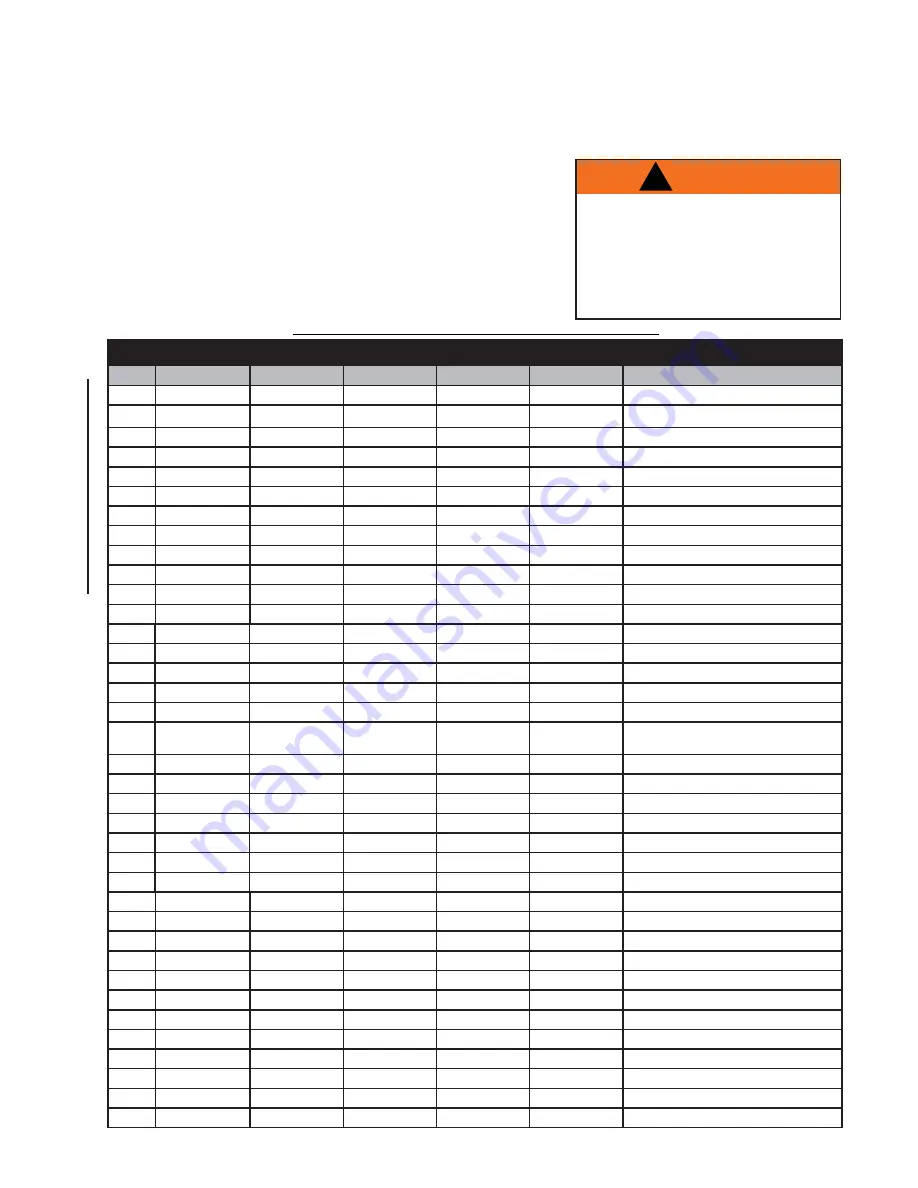

9.0 REPLACEMENTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally

all parts can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

•

Model & Serial Number of appliance

•

Installation date of appliance

• Part

number

•

Description of part

• Finish

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR

FURTHER INFORMATION, CONTACT YOUR AUTHORIZED DEALER.

41.1

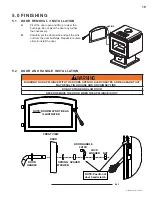

FAILURE TO POSITION THE PARTS

IN ACCORDANCE WITH THIS

MANUAL OR FAILURE TO USE ONLY

PARTS SPECIFICALLY APPROVED

WITH THIS APPLIANCE MAY

RESULT IN PROPERTY DAMAGE OR

PERSONAL INJURY.

!

WARNING

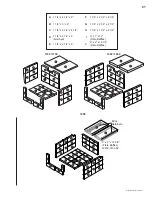

COMPONENTS

REF #

1100

1150

1400

1450

1900

DESCRIPTION

A

W090-0001

W090-0001

W090-0001

W090-0001

W090-0001

BRICK

B

W090-0002

W090-0002

W090-0002

W090-0002

W090-0002

BRICK

C

W090-0003

W090-0003

N/A

N/A

W090-0003

BRICK

D

W090-0004

W090-0004

W090-0004

W090-0004

W090-0004

BRICK, LEFT

D

W090-0005

W090-0005

W090-0005

W090-0005

W090-0005

BRICK, RIGHT

E

W090-0018

W090-0018

W090-0018

W090-0018

W090-0018

BRICK

F

W090-0019

W090-0019

W090-0019

W090-0019

W090-0019

BRICK

G

W090.0016

W090.0016

W090.0016

N/A

W090.0016

BRICK

H

W090-0017

W090-0017

W090-0017

N/A

W090-0017

BRICK

I

W018-0077

W018-0077

N/A

N/A

N/A

BAFFLE, FIBRE

J

N/A

N/A

W018-0078

W018-0078

W018-0130

BAFFLE, FIBRE

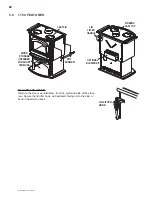

12

W135-0238

W135-0238

W135-0238

N/A

W135-0238

CAST ASH LIP

13

W010-0347

W010-0347

W010-0347

W010-0347

W010-0347

AIRWASH GASKET & SHIELD

14*

W570-0007

W570-0007

W570-0007

W570-0007

W570-0007

SCREWS FOR MANIFOLD SHIELD

15

GZ552

GZ552

GZ552

GZ552

GZ552

REPLACEMENT FAN

16

W325-0045

W325-0033

W325-0045

W325-0045

W325-0045

SPRING HANDLE LARGE

17

W325-0044

W325-0032

W325-0044

W325-0044

W325-0044

SPRING HANDLE SMALL

18*

W018-0077 (#10)

W018-0077 (#10)

W018-0078 (#11)

W018-0078 (#11)

W018-0092 (#12)

W018-0093 (#13)

FIBRE BAFFLE

19*

EP-11MS

N/A

EP-14MS

EP-14MS

EP-19MS

MANIFOLD SHIELD

20

KB-35

N/A

KB-35

KB-35

KB-35

VARIABLE SPEED CONTROL C/W KNOB

21*

W580-0001

W580-0001

W580-0002

W580-0005

W580-0003

COMPLETE BRICK SET

22*

CL28

N/A

CL28

N/A

CL28

BLACK CANOPY LOUVRES

23*

CL28G

N/A

CL28G

N/A

CL28G

GOLD PLATED CANOPY LOUVRES

24

W010-0349

W715-0641

W010-0349

N/A

W010-0349

PEDESTAL TRIM

25

W010-0243

N/A

W010-0243

N/A

W010-0243

ASH PAN (NO FRONT PLATE)

26

W325-0011

N/A

W325-0011

N/A

W325-0011

ASH PAN HANDLE

27

W200-0077

N/A

GS-330K

N/A

GS-330K

BLACK TRIVET

28

N/A

W710-0030

N/A

W710-0025

N/A

ASH TRAY

29

N/A

W325-0041

N/A

N/A

N/A

ASH DRAWER HANDLE

30

N/A

W525-0024

N/A

N/A

N/A

POT FENDER

31*

N/A

W290-0101

N/A

N/A

N/A

LID GASKET

32

N/A

W135-0234**

N/A

N/A

N/A

CAST - FIREBOX TOP

33

N/A

W135-0235**

N/A

N/A

N/A

CAST - LID

34

N/A

W135-0236**

N/A

N/A

N/A

CAST - FLUE COLLAR

35

N/A

W135-0237**

N/A

N/A

N/A

CAST - PEDESTAL BASE

36

N/A

W135-0238**

N/A

N/A

N/A

CAST - ASH TRAY

37*

N/A

W325-0040

N/A

N/A

N/A

HANDLE - LID LIFTER

Summary of Contents for EPA 1100

Page 34: ...34 W415 0763 B 10 28 11 27 20 45 30 32 33 34 40 38 16 25 39 35 29 28 13 12 15 24 26 17 36...

Page 37: ...37 W415 0763 B 10 28 11 43 1 12 0 SERVICE HISTORY...

Page 38: ...38 W415 0763 B 10 28 11 13 0 NOTES 44 1...

Page 39: ...39 W415 0763 B 10 28 11 44 1...

Page 40: ...40 W415 0763 B 10 28 11 44 1...