EN

W415-3006 / A / 05.27.21

3

safety information

• This appliance is hot when operated and

can cause severe burns if contacted.

• Any changes or alterations to this

appliance or its controls can be

dangerous and is prohibited.

• Do not operate appliance before reading and

understanding operating instructions. Failure

to operate appliance according to operating

instructions could cause fi re or injury.

• Ensure the glass door is opened or removed

when lighting the pilot for the fi rst time and

when the gas supply has run out.

• Risk of fi re or asphyxiation, do not operate

appliance with fi xed glass removed and never

obstruct the front opening of the appliance.

• Do not connect 110 volts to the control valve,

with the exception of models; GSST8 and

GT8.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves, protective footwear, and safety glasses during

installation. Sheet metal edges may be sharp.

• Do not burn wood or other materials in this appliance.

• Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing

and operating the appliance.

• High pressure will damage valve. Disconnect gas supply piping before pressure testing gas line at

test pressures above 1/2 psig. Close the manual shut-off valve before pressure testing gas line at test

pressures equal to or less than 1/2 psig (35mb).

• The appliance must not be operated at temperatures below freezing (32°F / 0°C). Allow the appliance

to warm to above freezing prior to operation, with the exception of models; GSS36, GSS42; these

appliances are suitable for 0°F / -18°C.

• Children and adults should be alerted to hazards of high surface temperature and should stay

away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room as the

appliance. Toddlers, young children and others may be susceptible to accidental contact

burns. A physical barrier is recommended if there are at risk individuals in the house. To

restrict access to an appliance or stove, install an adjustable safety gate to keep toddlers,

young children and other at risk individuals out of the room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from

furniture and draperies.

• Furniture or other objects must be kept a minimum of 4 feet (1.22m) away from the front of the appliance.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot

surfaces.

• Even after the appliance is off, it will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children

from hot surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen, guard or barrier removed for servicing the appliance, must be replaced prior

to operating the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the

appliance and venting system are kept clean. The appliance and its venting system should be inspected

before use and at least annually by a qualifi ed service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. The appliance area must be kept clear and

free from combustible materials, gasoline and other fl ammable vapors and liquids.

• If the appliance shuts off, do not re-light until you provide fresh air. If appliance keeps shutting off, have it

serviced. Keep burner and control compartment clean.

• Under no circumstances should this appliance be modifi ed.

• Do not allow wind or fans to blow directly into the appliance. Avoid any drafts that alter burner fl ame

patterns.

LA VITRE CHAUDE CAUSERA

DES BRÛLURES.

NE PAS TOUCHER LA VITRE

AVANT QU’ELLE AIT REFROIDI.

NE JAMAIS LAISSER LES

ENFANTS TOUCHER LA VITRE.

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

!

DANGER

!

AVERTISSEMENT

A barrier designed to reduce the risk of burns from the hot

viewing glass is provided with this appliance and must be

installed for the protection of children and other at-risk

individuals.

Une barriére conçu à réduire le risque de brûlures causées

par le verre chaud est fourni avec l’appareil et doit être

installé pour la protection des enfants et d’autres

personnes à risque.

HEISSES GLAS FÜHRT ZU

VERBRENNUNGEN.

BERÜHREN SIE DAS GLAS ERST,

WENN ES ABGEKÜHLT IST.

LASSEN SIE KINDER NIEMALS

DAS GLAS BERÜHREN.

!

GEFAHR

Mit diesem Gerät erhalten Sie eine Sicherheitsbarriere, die

zum Schutz von Kindern und anderen gefährdeten

Personen installiert werden sollte, um das Risiko von

Verbrennungen durch das heiße Sichtglas zu verringern.

FRENCH

GERMAN

HEET GLAS VEROORZAAKT

BRANDWONDEN.

RAAK HET GLAS NIET AAN TOT

HET IS AFGEKOELD.

LAAT KINDEREN NOOIT HET

GLAS AANRAKEN.

!

GEVAAR

Dit apparaat is voorzien van een barrière die is ontworpen om het

risico van brandwonden door het hete kijkglas te beperken. Deze

barrière moet worden geïnstalleerd ter bescherming van kinderen

en personen uit andere kwetsbare groepen die gevaar lopen.

DUTCH

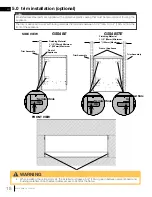

3.1C

!

WARNING

!

WARNING

• Do not use a blower insert, heat exchanger insert or other accessory not approved for use with this

appliance.

• This appliance must not be connected to a chimney fl ue pipe serving a separate solid fuel burning

appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician

to inspect the appliance and to replace any part of the control system and any gas control which has

been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass

should be done by a licensed or qualifi ed service person, if equipped.

• Do not strike or slam shut the appliance glass door, if equipped.

• Only doors / optional fronts certifi ed with the appliance are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As

with all plastic bags, these are not toys and should be kept away from children and infants.

• Carbon or soot should not occur in a vent free appliance as it can distribute into the living area of your

home. If you notice any signs of carbon or soot, immediately turn off your appliance and arrange to have

it serviced by a qualifi ed technician before operating it again.

• If equipped, the screen must be in place (closed) when the appliance is in operation.

• When equipped with pressure relief doors, they must be kept closed while the appliance is operating

to prevent exhaust fumes containing carbon monoxide, from entering into the home. Temperatures of

the exhaust escaping through these openings can also cause the surrounding combustible materials to

overheat and catch fi re.

• Carbon monoxide poisoning may lead to death; early signs of carbon monoxide poisoning resemble the

fl u, with headache, dizziness and/or nausea. If you have these signs, the appliance may not be working

properly. Get fresh air at once! Have appliance serviced. Some people; pregnant women, persons with

heart or lung disease, anemia, those under the infl uence of alcohol, those at high altitudes are more

affected by carbon monoxide than others. Failure to keep the primary air opening(s) of the burner(s) clean

may result in sooting and property damage.

• As with any combustion appliance, we recommend having your appliance regularly inspected and

serviced as well as having a Carbon Monoxide Detector installed in the same area to defend you and

your family against Carbon Monoxide (not applicable for outdoor appliances).

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the

appliance. Elevated temperatures on the wall or in the air above the appliance can cause melting,

discolouration or damage to decorations, a TV or other electronic components.

• For appliances equipped with a safety barrier; if the barrier becomes damaged, the barrier

shall be replaced with the manufacturer’s barrier for this appliance.

• Installation and repair should be done by a qualifi ed service person. It is imperative that control

compartments, burners and circulating air passageways of the appliance be kept clean.

• For outdoor products only: this appliance must not be installed indoors or within any structure that

prevents or inhibits the exhaust gases from dissipating in the outside atmosphere.

• If applicable, the millivolt version of this appliance uses and requires a fast acting thermocouple. Replace

only with a fast acting thermocouple supplied by Wolf Steel Ltd.

!

WARNING

!

Disconnect the appliance main gas valve/control

from the supply piping when pressure testing that

system at pressures in excess of 1/2 psi (3.5 kPa).

Isolate the appliance with it’s shut off valve during

any pressure testing of the supply piping at

pressures equal to or less than 1/2 psi (3.5 kPa).

FIRE RISK HAZARD / DELAYED IGNITION

High supply pressure will damage the valve / controls.

Add California Prop 65 warning