12

WS-415-63 / 11.24.98

OPERATION / MAINTENANCE

OPERA

OPERA

OPERA

OPERA

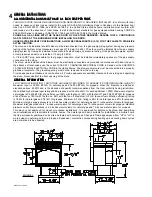

OPERATING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONS

The on-off switch is located on the back of the unit at the top left corner. When lit for the first time, the fireplace will

emit a slight odour for a few hours. This is a normal temporary condition caused by the curing of the logs and the

"burn-in" of internal paints and lubricants used in the manufacturing process and will not occur again. Simply

open a window to sufficiently ventilate the room. After extended periods of non-operation such as following a

vacation or a warm weather season, the fireplace may emit a slight odour for a few hours. This is caused by dust

particles in the heat exchanger burning off. Open a window to sufficiently ventilate the room.

INSTRUCTIONS TO TURN OFF GAS:

1.

Turn off all electrical power to the unit if service is to

be performed.

2.

Push in gas control knob slightly and turn clockwise

to off. DO NOT FORCE.

When lighting and re-lighting, the gas knob cannot

be turned from pilot to off unless the knob is

depressed slightly.

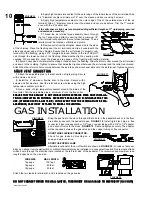

1.

Stop! Read the above safety information

on this label.

2.

Turn off all electric power to the fireplace.

3.

Turn the gas knob clockwise

to off.

4.

Wait five (5) minutes to clear out any gas. If you

smell gas including near the floor. Stop! Follow "B"

in the above safety information on this label. If you

don't smell gas go the next step.

5.

Turn gas knob counter-clockwise

to pilot.

6.

Depress slightly and hold gas knob while lighting the pilot

with the push button ignitor. Keep knob depressed for one

minute, then release. If pilot does not con-

tinue to burn, repeat steps 3 through 5.

7.

With pilot lit, depress and turn gas knob

counter-clockwise

to on.

8.

If equipped with remote on-off switch/thermostat,

main burner may not come on when you turn valve to on. Re-

mote switch must be in the on position to ignite burner.

9.

Turn on all electric power to the fireplace.

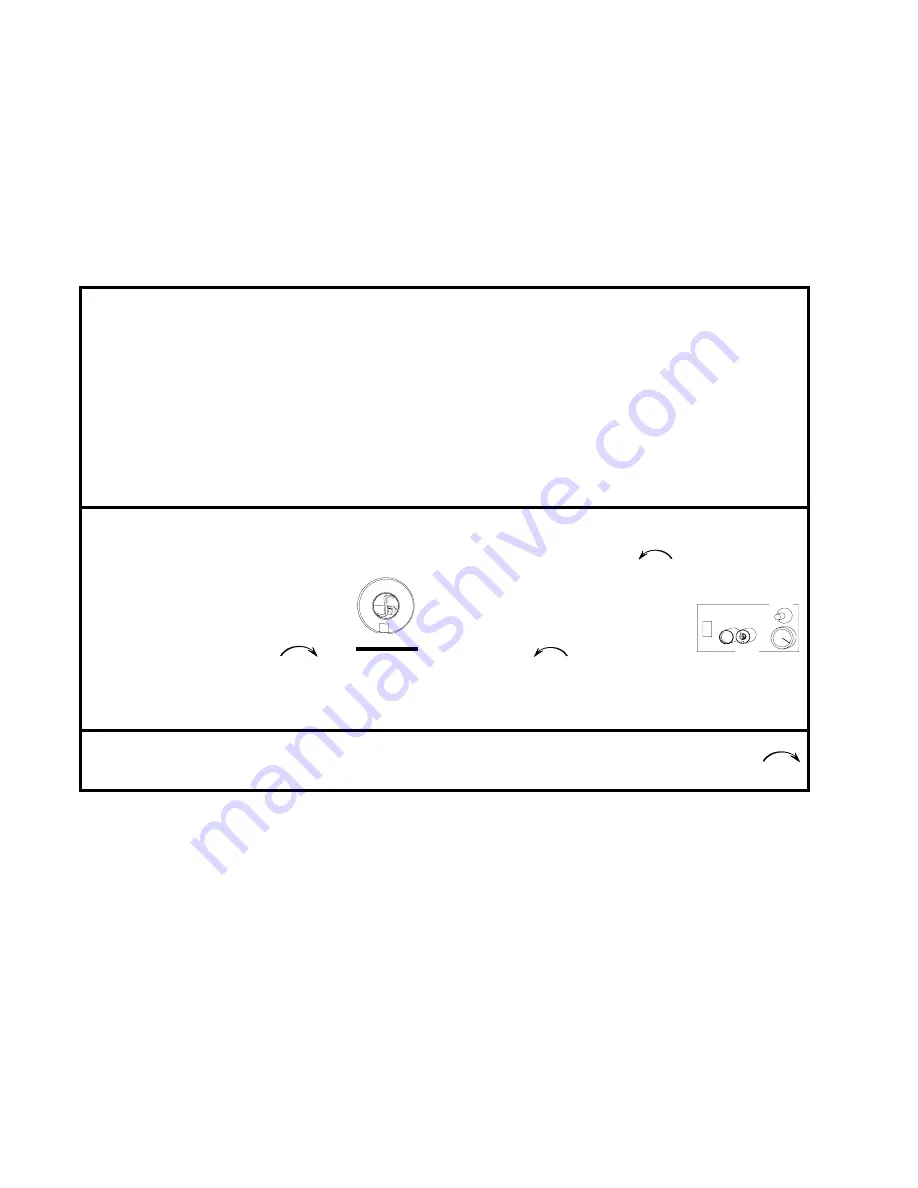

P

I

N

O

L

O

T

FF

O

GAS KNOB

LO

FLAME

KNOB

ADJUSTMENT

I H

VARIABLE

SPEED

SWITCH

L

P

O

FF

N

T

I

O

O

PILOT

KNOB

ON/OFF

IGNITOR

PIEZO

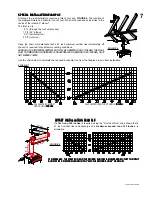

LIGHTING INSTRUCTIONS:

WARNING

The gas valve has an interlock device which will not allow the pilot burner to be

lit until the thermocouple has cooled. Allow approximately 60 seconds for the thermocouple to cool.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbour's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

FOR YOUR SAFETY READ BEFORE OPERATING

A.

This fireplace is equipped with a pilot which must be lit by hand while following these instructions exactly.

B.

Before operating smell all around the fireplace area for gas and next to the floor because some gas is heavier than

air and will settle on the floor.

C.

Use only your hand to turn the gas control knob. Never use tools. If the knob will not turn by hand, do not try to

repair it. Call a qualified service technician. Force or attempted repair may result in a fire or explosion.

D.

Do not use this fireplace if any part has been under water. Immediately call a qualified service technician to inspect

the fireplace and replace any part of the control system and any gas control which has been under water.

WHAT TO DO IF YOU SMELL GAS:

• Turn off all gas to the fireplace.

• Open windows.

• Do not try to light any appliance.

1.

In order to properly clean the burner and pilot as-

sembly, remove the logs to expose both assemblies.

2.

Keep the control compartment, logs, burner, air

shutter opening and the area surrounding the logs

clean by vacuuming or brushing,

at least once a year

.

3.

Check to see that all burner ports are burning.

Clean out any of the ports which may not be burning

or are not burning properly. (end brick panel must be

removed in order to facilitate burner removal, where

applicable.)

4.

Check to see that the pilot flame is large enough to engulf

the thermocouple and thermopile and reaches toward the burner

with the third jet.

5.

Replace the cleaned logs.

6.

Check to see that the main and runner burners ignite com-

pletely on all openings when the gas knob for the burners is

turned on. A 5 to 10 second total light-up period is satisfactory.

If ignition takes longer, consult your Napoleon dealer / distribu-

tor.

7.

Check that the gasketing on the sides, top and bottom of the

door is not broken or missing. Replace if necessary.

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE FIREPLACE.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and danger-

ous operation. Verify proper operation after servicing. This fireplace and its venting system should be inspected before

use and at least annually by a qualified service person. The fireplace area must be kept clear and free of combustible

materials, gasoline or other flammable vapours and liquids. The flow of combustion and ventilation air must not be

obstructed.