13

WS-415-63 / 11.24.98

ADJUSTMENTS

PILOT BURNER ADJUSTMENT

PILOT BURNER ADJUSTMENT

PILOT BURNER ADJUSTMENT

PILOT BURNER ADJUSTMENT

PILOT BURNER ADJUSTMENT

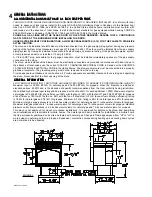

Adjust the pilot screw to provide properly

sized flame. Turn in a clockwise direc-

tion to reduce the gas flow.

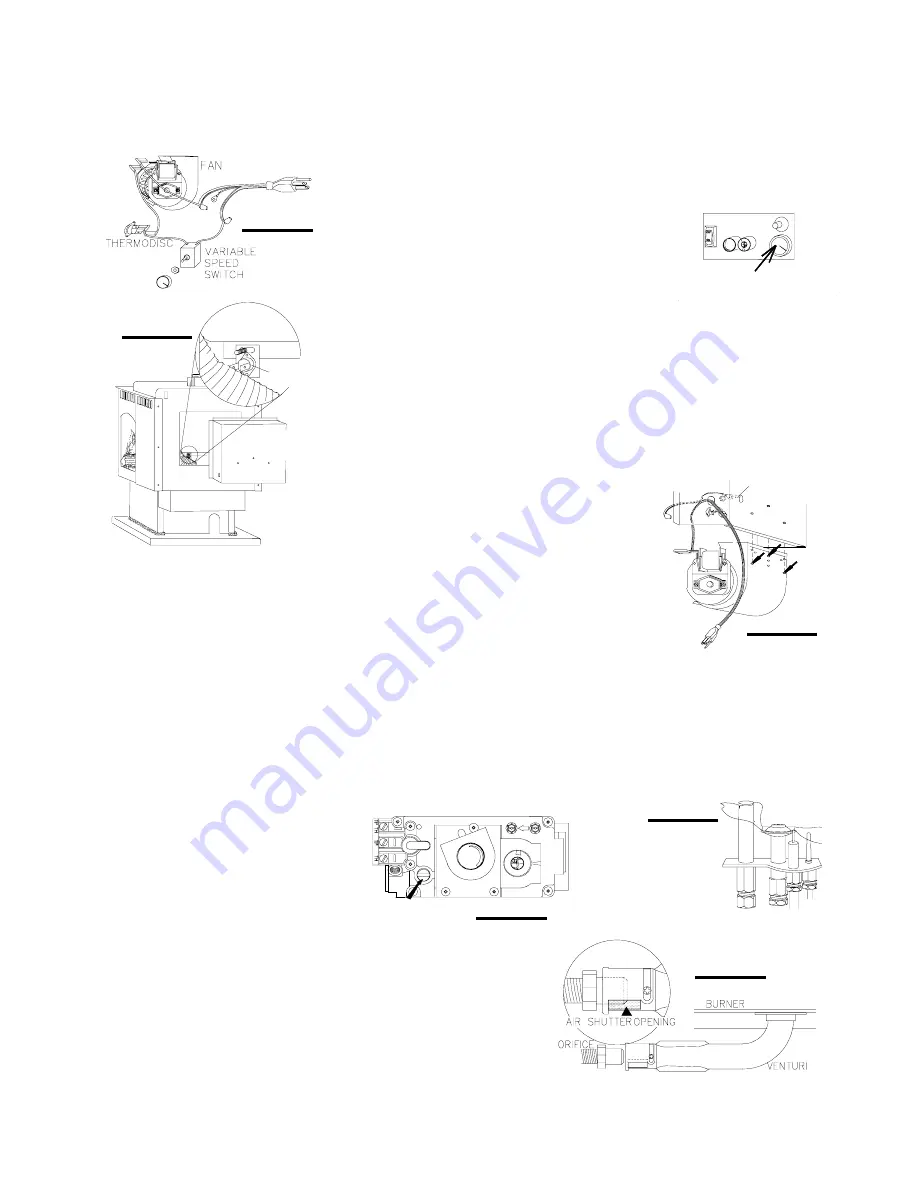

FIGURES 26 & 27.

VENTURI ADJUSTMENT

VENTURI ADJUSTMENT

VENTURI ADJUSTMENT

VENTURI ADJUSTMENT

VENTURI ADJUSTMENT

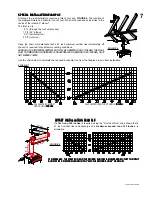

To access the venturi, remove the four screws securing the burner to the

base; slide to the left, lift up and out. Natural gas models have air shut-

ters set at 3/16 (.188) inch open. Propane gas models have air shutters

set at 1/4 (.250) inch open. Closing the air shutter will cause a more

yellow flame, but can lead to carboning. Opening the air shutter will cause

a more blue flame, but can cause flame lifting from the the burner ports.

The flame may not appear yellow immediately; allow 15 to 30 minutes for

the final flame colour to be established.

P

I

PI

PILOT SCREW

LOT

N

O

L

O

T

H I

LO

FF

O

FIGURE 26

FLAME MUST ENVELOP

UPPER 3/8" TO 1/2" OF

THERMOCOUPLE &

THERMOPILE

THERMOPILE

THERMO-

COUPLE

FIGURE 27

FIGURE 28

Air shutter adjustment must only be done by a qualified gas installer!

OPTIONAL BLOWER INSTALLATION

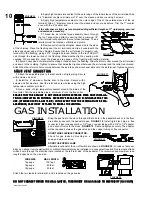

Provision has been made on the Napoleon stove to install an optional blower on

the rear wall. Because the blower is thermally activated, when turned on, it will

automatically start after approximately 30 minutes from a cold start (pilot off) or

15 minutes from a warm start (pilot on) and will run for approximately 30 minutes

after the stove has been turned off. Use of the fan in-

creases the output of heat.

1.

Mount the variable speed switch: insert the rheostat

stem through the 3/8" diameter hole in the pedestal

and from the front secure with the pal nut. Add the knob.

2.

Remove the blower housing located at the rear of the

stove. Attach the bracket holding the heat sensor as shown to the weld stud and

secure using one of the #6 nuts.

FIGURE 24.

3.

Attach the bare end of the wire (with one bare lead / one flag connector end) to

the

black

wire of the speed switch using a nut connector. Attach the flag connec-

tor at the other end to one of the prongs of the heat sensor.

4.

Thread the leads of the power cord through the slot located at the bottom left

of the blower housing. Attach the terminal of the ground wire

(green)

to the

threaded weld stud and secure with a nut.

5.

Connect one of the two bare leads of the other wire to the

white

wire of the

speed switch using a nut connector. Connect the other end to the bare lead wire

of the blower cord using a nut connector.

6.

Attach the other terminal of the wire

(already at-

tached to the blower)

to the heat sensor.

7.

Mount the cord terminal to the other blower prong.

8.

Using the holes shown, attach the blower to the

blower housing.

9.

Bring out any slack in the blower cord. Place the cord into the split strain relief bushing,

just at the point where the cord enters the slot. Clamp the two pieces together and insert

the bushing securely into the slot.

FIGURE 25.

VARIABLE SPEED

SWITCH

H

I

L

P

O

FF

N

T

I

O

O

LO

GROUND

WELD STUD

FIGURE 25

white

black

ground

FIGURE 23

SENSOR

BLOWER

HOUSING

HEAT

FIGURE 24