7

WS-415-63 / 11.24.98

SPECIAL INST

SPECIAL INST

SPECIAL INST

SPECIAL INST

SPECIAL INSTALLA

ALLA

ALLA

ALLA

ALLATION EXAMPLE

TION EXAMPLE

TION EXAMPLE

TION EXAMPLE

TION EXAMPLE

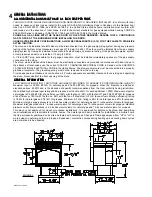

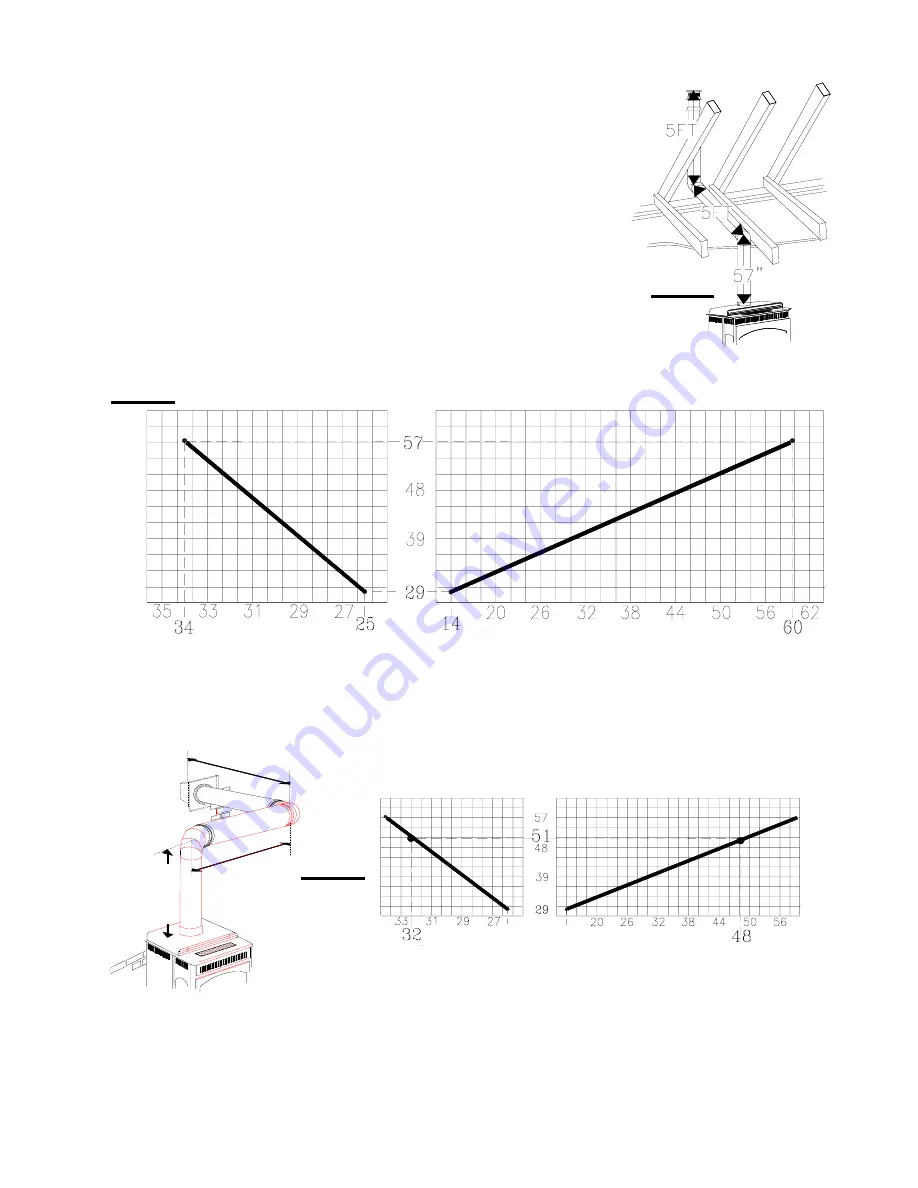

A through the roof installation requires a total 5 foot rise.

FIGURE 6.

The location of

the fireplace dictates a horizontal run of 5 feet. What is the required vertical rise to the

centre of the initial 90° elbow?

The total run is:

5 ft. (through the roof vertical rise)

10 ft. (90° elbow)

5 ft. (horizontal run)

20 ft. (total run)

Using the chart, will determine that a 57 inch minimum vertical rise immediately off

the unit is required for satisfactory venting conditions.

ALTHOUGH THE IMMEDIATE VERTICAL RUN MAY BE GREATER THAN 57 INCHES, THE MAXI-

MUM COMBINATION OF HORIZONTAL AND VERTICAL RUNS, BEYOND THE 57 INCHES,

MUST

NOT EXCEED 20 FEET.

Use the chart below to calculate the required horizontal run from the fireplace in an offset installation.

FIGURE 6

FIGURE 7

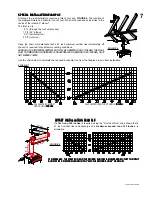

OFFSET INST

OFFSET INST

OFFSET INST

OFFSET INST

OFFSET INSTALLA

ALLA

ALLA

ALLA

ALLATION EXAMPLE

TION EXAMPLE

TION EXAMPLE

TION EXAMPLE

TION EXAMPLE

If a

first run of 48 inches

is required, using the "First Vent Run" chart shows that a

51 inch vertical rise is necessary and a

maximum second run of 32 inches

is

allowable.

IF NECESSAR

IF NECESSAR

IF NECESSAR

IF NECESSAR

IF NECESSARYYYYY, THE FIRST RUN AND THE SECOND RUN MA

, THE FIRST RUN AND THE SECOND RUN MA

, THE FIRST RUN AND THE SECOND RUN MA

, THE FIRST RUN AND THE SECOND RUN MA

, THE FIRST RUN AND THE SECOND RUN MAY BE REVERSED SO THA

Y BE REVERSED SO THA

Y BE REVERSED SO THA

Y BE REVERSED SO THA

Y BE REVERSED SO THAT THE FIRST

T THE FIRST

T THE FIRST

T THE FIRST

T THE FIRST

RUN MA

RUN MA

RUN MA

RUN MA

RUN MAY BE A MAXIMUM LENGTH OF 34" AND THE SECOND RUN 60" MAXIMUM.

Y BE A MAXIMUM LENGTH OF 34" AND THE SECOND RUN 60" MAXIMUM.

Y BE A MAXIMUM LENGTH OF 34" AND THE SECOND RUN 60" MAXIMUM.

Y BE A MAXIMUM LENGTH OF 34" AND THE SECOND RUN 60" MAXIMUM.

Y BE A MAXIMUM LENGTH OF 34" AND THE SECOND RUN 60" MAXIMUM.

14" MIN

60" MAX

57"

MAX

29"

MIN

second run

first run

25" MIN

34" MAX

FIGURE 8

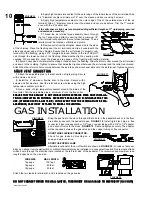

CALCULATED

SECOND

VENT RUN IN INCHES

INCHES

INCHES

INCHES

INCHES

CALCULATED

FIRST VENT RUN IN INCHES

INCHES

INCHES

INCHES

INCHES