10

WS-415-131 / A / 09.11.00

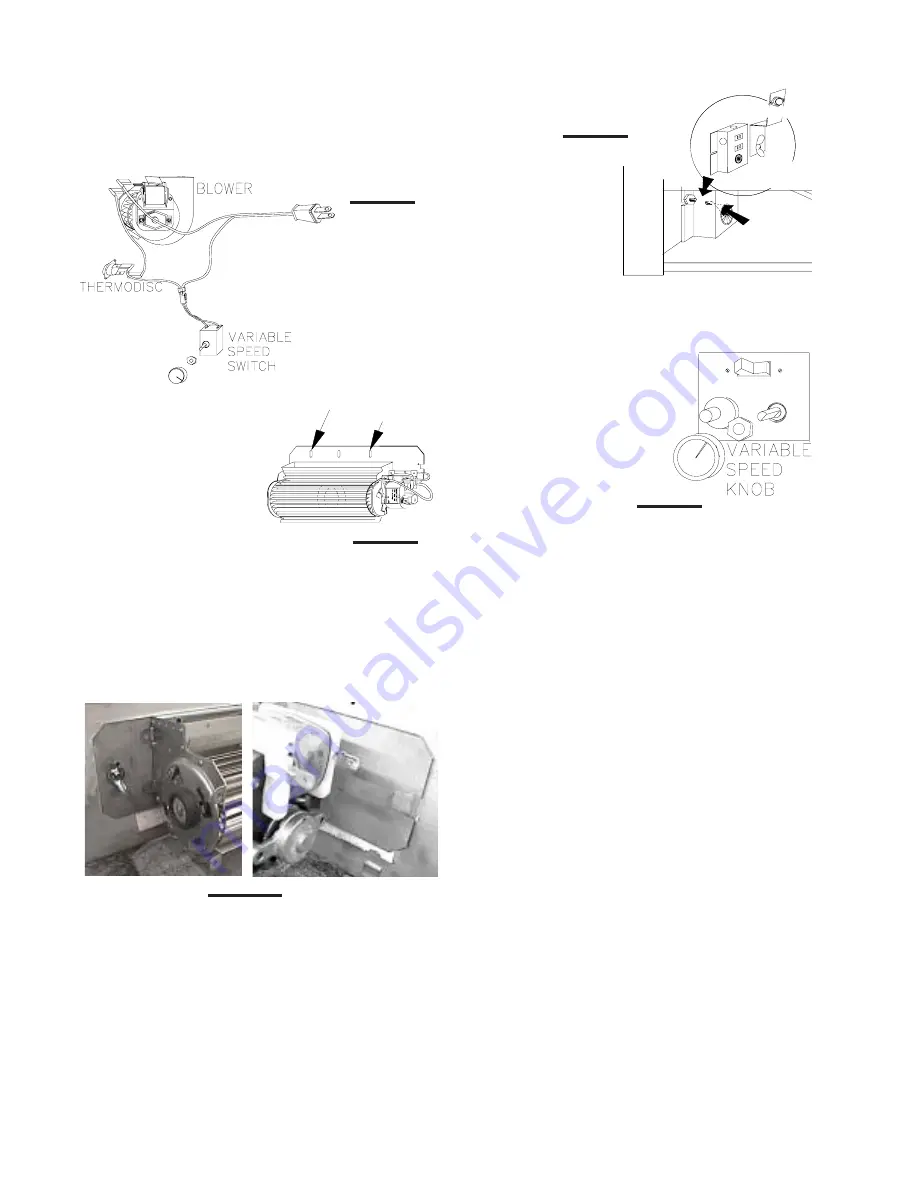

BLOWER INSTALLATION

INSTALLATION TO BE DONE BY A QUALIFIED INSTALLER

and must be electrically connected and grounded in accord-

ance with local codes. In the absence of local codes, use the

current ANSI/NFPA 70-1996

NATIONAL

ELECTRICAL

CODE

.

If the fireplace was

not previously

equipped with a

blower:

route a

grounded 2-wire, 60hz

power cable to the junc-

tion box. At this point, it

must be strain relieved

and insulated.

The three slots on the

blower mounting bracket

allow ease of adjustment

when attaching the

blower. For a quiet run-

ning blower, do not allow

the assembly to sit on the

firebox base.

Slide the vibration reducing pad

(A)

into the clip

(C)

and up

against the threaded stud

(B)

at the other end. The blower

must be able to be positioned entirely onto the pad.

Tilt the blower onto its side. Slide it past the controls and

into the clip

(C)

. Secure to the threaded stud using the lock

washer and wing nut provided. Ensure that the blower

does not touch the fireplace base or the firebox.

Attach the connectors from the black and white wires to the

thermodisc and secure the thermodisc bracket to the se-

curing stud at the bottom left of the unit using a lock washer

and wing nut. Ensure that the thermodisc touches the fire-

box wall.

Attach the connectors from the

black and red wires to the

blower.

Attach and secure the variable

speed switch using the nut pro-

vided. Plug the harness cord

into the receptacle.

The wire harness provided in this kit is a universal

harness. When installed, ensure that any excess

wire is contained, preventing it from making con-

tact with moving or hot objects.

Because the blower is thermally activated, when

turned on, it will automatically start approximately

10 minutes after lighting the fireplace and will run

for approximately 30-45 after the fireplace has

been turned off. Use of the fan increases the out-

put of heat.

Drywall dust will penetrate into the blower bear-

ings causing irreparable damage. Care must be

taken to prevent drywall dust from coming into

contact with the blower or its compartment. Any

damage resulting from this condition is not cov-

ered by the warranty policy.

red

white

black

RECEPTACLE /

THERMODISC

GROUND

SCREW

JUNCTIONBOX

SLOTS

ELONGATED

FIGURE 16

FIGURE 17

C

A

B

FIGURES 18

FIGURE 19

FIGURE 20