W415-1066 / A / 03.06.12

12

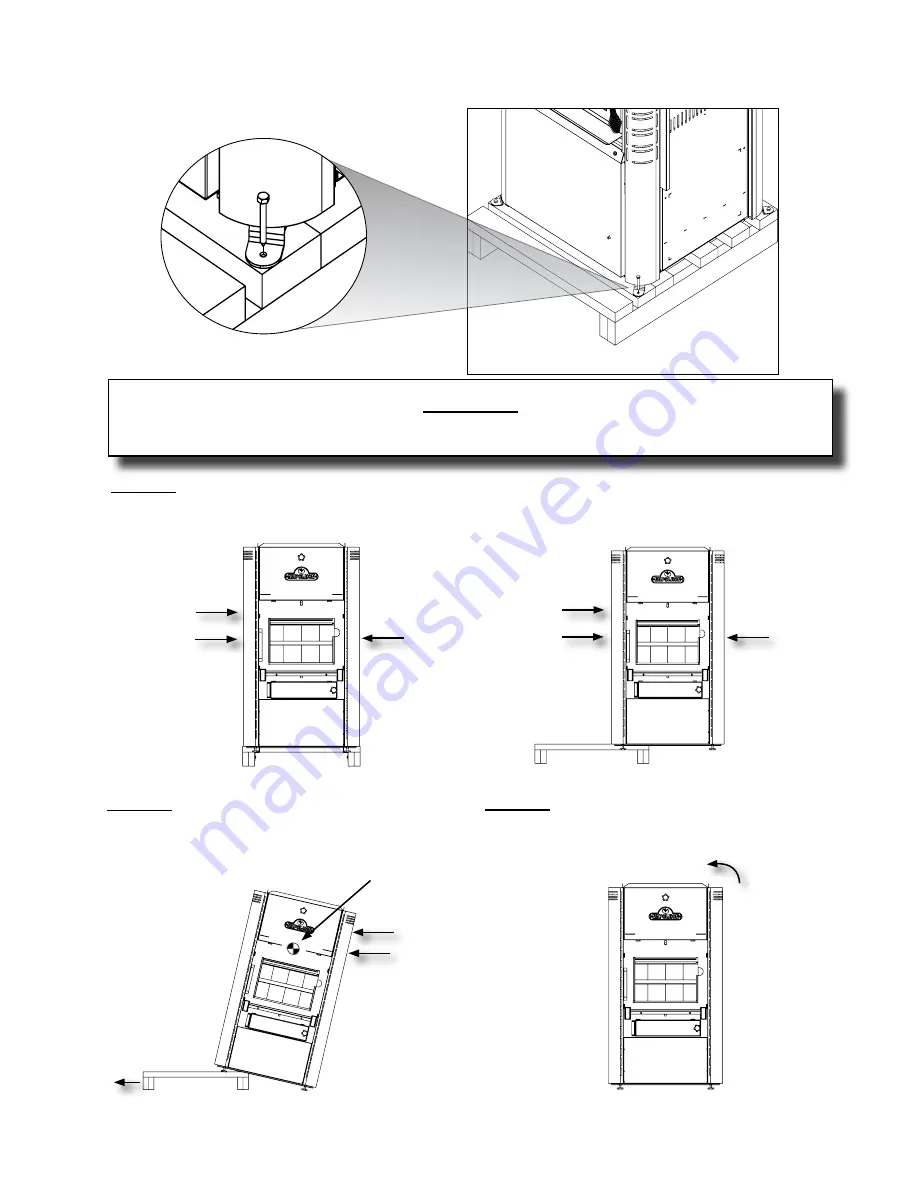

CAUTION

high cenTre of grAviTy! uSe eXTreme cAuTion To Avoid ToPPling of The furnAce

"cruSh hAzArd"!

sTEp #1:

Push the furnace to one side until close to the weight tipping the skid.

sTEp #2:

firmly support side of the furnace (near top) to

prevent furnace toppling, when the skid/furnace are

tilted.

high cenTre

of grAviTy

2nd inSTAller

SuPPorTS

WeighT of uniT

from ToP

inSTAller #1

inSTAller #2

inSTAller #2

inSTAller #1

sTEp #3:

Pull the skid from under the unit, and gently tilt the

furnace upright onto the levelling feet.

UsE ExTREME

CAUTION TO AvOID

TOppLINg OF UNIT,

"CRUsH HAzARD".

4.3 rEmOvAL OF FurNACE FrOm BASE OF SkId

noTe - hmf150 model ShoWn