Shut down

1.

Turn the control knob to “0" setting.

2.

Lift the safety lever.

3.

Turn off the oil tank fuel supply valve.

The oil tank fuel supply valve should always be shut off when the oil stove is not in operation.

ADJUSTMENTS

Oil flow adjustments

The oil flow setting is done by the manufacturer and

normally should not require any adjustments. These

adjustments if required must be done by a qualified

technician.

Always burn the stove on low for at least 15 minutes before

attempting to adjust the flow.

Turn the screw only a quarter turn at a time. Walt 10 to

15 minutes between adjustments to allow the fire to

stabilise.

If the burner fails to respond to the control knob settings,

other possible causes should be checked (chimney draft,

dirty filter or the oil supply line) prior to attempting to adjust

the carburetor.

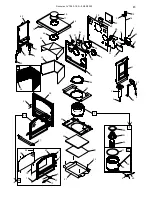

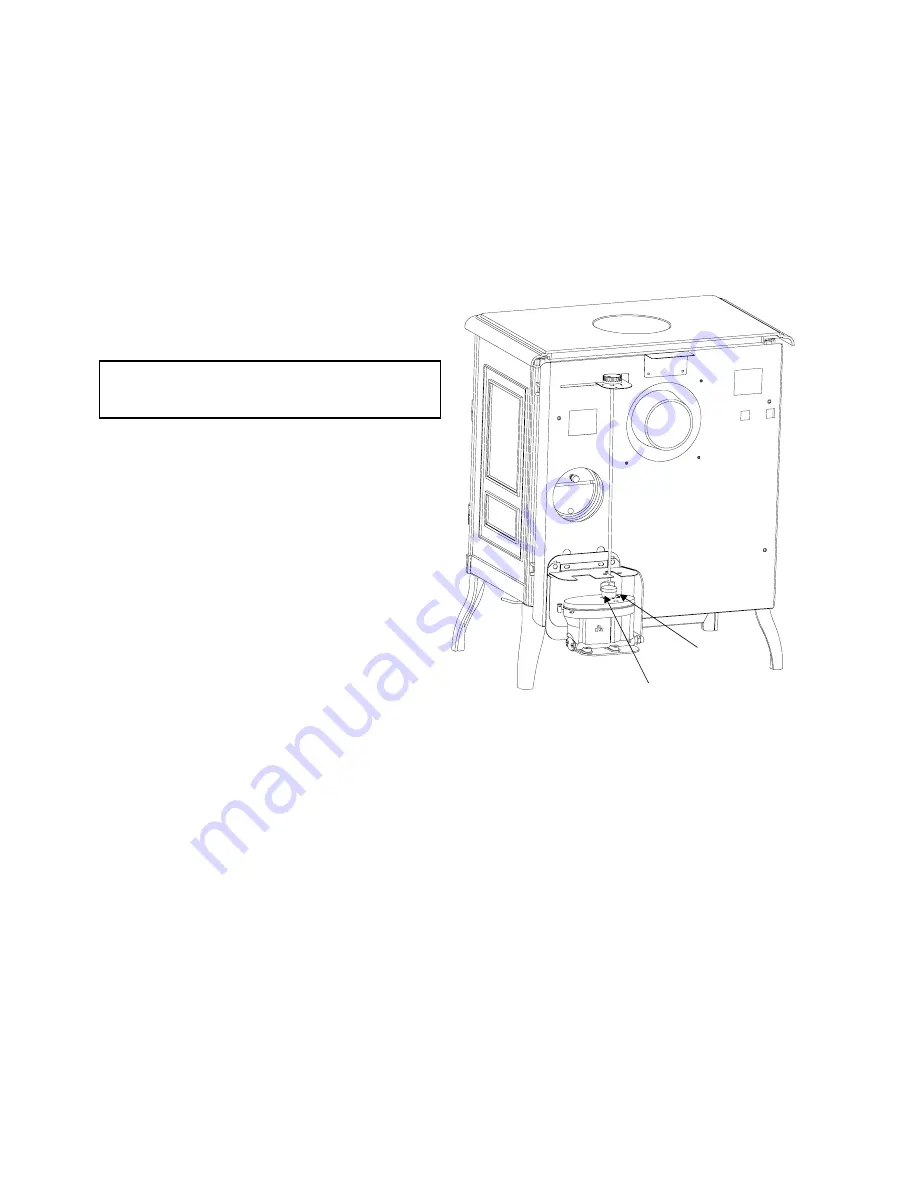

Adjustment at minimum speed ( figure 16) :

Turn the control knob

‘A’

to the (1) dial setting and allow

the burner to run for a few minutes. The flame must

completely cover the bottom of the burner pot and the

catalyser should glow red. If the flame is too small, the oil

stove will quickly soot up. Turn the set screw

‘B’

, located

on the top of the carburetor, clockwise with a screwdriver to

increase the flow of oil.

If the flame is too high, reduce the oil flow by turning the set

screw counter-clockwise. The flames should be blue with

occasional yellow tips. The catalyser should glow red.

Adjustment at maximum speed (figure 16) :

Gradually turn the control knob

‘A’

to dial setting (6) and

allow the burner to run for a few minutes. The flame should

be in a cone form with the top level with the upper part of

the door. If the flame is too low, the oil flow rate should be

increased by turning the set screw ‘

C

’ on the carburetor

counter-clockwise.

If the flame is too high, turn the screw clockwise. The flames should have only occasional contact with the burner ring. The

bottom 2" (50 mm) of the flames should be blue in colour with the remaining portion yellow.

Chimney draft adjustment

A volume of air, depending on height and diameter of the flue system, is contained in the chimney. This air starts to rise as it

is heated by the burning stove and begins the draft cycle. The amount of draft depends on the volume of air within the

chimney system and the temperature of that air. Too large a flue could cause cooling of the flue gases, resulting in a poor

draft and stove performance.

The stove is equipped with a draft regulator to ensure a constant and stable air intake despite external variations in wind

strengths and other factors.

Adjustments to the draft with the regulator should be carried out when the chimney is hot (after a minimum 30 minutes of

operations).

See Page 4 and Page 5, General information, for chimney draft requirement.

Overheating

Adjusting the control knob to a high setting prematurely allows too much oil to enter the burning pot. This and/ or the lack of

sufficient draft creates a fire intensity which in turn creates vibrations. Similarly, if the oil stove or the chimney connector

start to glow red, the appliance is being overheated. Turn off the oil supply until the fire has decreased to a normal steady

burn. Adjust draft to specifications.

Adjustments, if any, to your oil stove have been made by your installer. Do not attempt any further adjustments yourselves

but report any failures or shortcomings in the stove’s performance to your authorized dealer.

Document n° 1092-1 EN ~ 04/02/2002

10

Figure 16

A

B

C