15

W415-0847 / A / 06.08.10

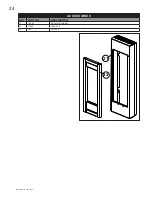

5.3 FRAME

INSTALLATION

CONTROL DOOR

BOTTOM

TRIM

BRACKET

W385-0479

W385-0479

5.3.1

Align the two holes in the

upper portion of the hinge

on the control door to those

in the bottom trim bracket,

secure using two of the #8

x 1/2” hex head screws

supplied.

5.3.2

Install the top trim bracket to

the

fi

rebox using the three

#9 - 14 x 1/2” hex head

screws supplied in the

manual baggie.

5.3.3

Rest the top lip of the

frame on the top trim bracket, and

the securing tabs at the bottom of the

frame on the bottom

trim bracket.

5.3.4

Align the two slots in the top of the

frame with the two holes

in the top trim bracket and secure using the two #10 pan head screws

supplied however do not fully tighten to leave room for adjustment.

5.3.5

Align the holes in the securing tabs at the bottom of the

frame with the holes in the bottom trim bracket and secure using the

two remaining #8 x 1/2” hex head screws, however do not fully tighten

to leave room for adjustment.

5.3.6

If required, the bottom trim bracket can be adjusted by loosening it’s securing

screws.

5.3.7

Once

the

frame is perfectly square and the control door will close without

rubbing against the sides of the

frame, tighten all screws.

5.3.8

Open the control door.

5.3.9

Insert the door stop chain into the receiving slot in the control door.

5.3.10

Insert the door stop chain into the receiving slot in the

frame so that when

fully open the control door has a clear-

ance of 1/8” to the

fi

nished wall.

NOTE:

In most cases, a count of 9 balls

between receiving slots will give the

desired clearance.

5.3.11

Close the control door.

The

frame has been designed to accom-

modate

fi

nished material thicknesses of .500” - .750”.

If it is necessary to pull the

frame out to the

max. .750” the magnetic catch will need to be adjusted.

Minor adjustment can be made by removing shims

from behind the magnet. Major adjustments can be made

by moving the magnet to the outside of the panel.

Adjustment may be required to accommodate the door stop chain slack when the control door is closed. The control door

securing screws can be loosened to allow adjustment. Before re-tightening the screws ensure the control door is still re-

cessed into the

frame at a similar offset to the top trim piece.

RECEIVING

SLOTS

DOOR

STOP

CHAIN

FRAME

TOP

TRIM

BRACKET

BOTTOM

TRIM

BRACKET

W385-0479