MANUAL OF

USE AND MAINTENANCE

ATLANTIC 100

P g .

|

5

ATLANTIC 100 - Rev.00/16 Cod. AT200-002

- Carefully monitor the condition of the reservoir.

- Never exceed the maximum operating pressure of the reservoir.

- If the reservoir is damaged it must be immediately and entirely replaced.

- The reservoir must be checked and documented in its entirety, with every individual component fitted. It is forbidden to replace any

components without carrying out a subsequent check procedure.

- Regularly check the reservoir internally and externally for any damage caused by corrosion.

- For improved safety NARDI COMPRESSORI recommend replacing the reservoir every 15 years.

GENERAL SAFETY:

1.

Operators authorized to use the machine must be aware of all the operating rules and machine controls, the instruments,

indicators, and various sticker symbols.

2.

Always have first aid materials and a CO2 fire extinguisher on hand. Ensure that the extinguisher is always full and operational.

3.

When using the compressor wear suitable protective clothing including work shoes, protective goggles, gloves, etc.

4.

Always disconnect the power supply cable when carrying out operations inside the compressor. Never carry out operations on

the machine with the electrical power connected or during operation.

GUARANTEE/WARRANTY AND ASSISTANCE

COMPRESSOR GUARANTEE/WARRANTY:

The

ATLANTIC

compressor produced by

NARDI COMPRESSORI

is guaranteed for a period of twelve months from the date of purchase as

indicated on the machine ID plate.

At the time of production and testing a plate is applied making the machine

compliant with EC standards

and bearing the CE symbol. The

GUARANTEE is invalidated if this plate is removed or altered.

The guarantee is only valid if the purchaser has fulfilled all the contractual rules and if the compressor has been used as indicated without being

subject to tampering or modifications, unless agreed and confirmed by NARDI COMPRESSORI.

The guarantee is not applicable:

-

If the machine has been used incorrectly (not as indicted in the present Manual of Use and Maintenance).

-

For consumable materials and those object of routine maintenance, in particular if utilized improperly.

-

If non original NARDI COMPRESSORI spare parts are used.

-

If gasses other than air, or air with percentages of oxygen above 21% are drawn in/compressed.

Replacement of faulty parts will be made free of charge at the Montecchio Maggiore site of Nardi Compressori, or at the premises of one of our

authorized retailers.

Repairs and replacements conducted by NARDI COMPRESSORI or an authorized retailer, during the period of guarantee, do not extend the

guarantee period.

If repairs are conducted outside of Nardi Compressori, the delivery expenses for the spare parts will be charged (defective components must only

be replaced by technically trained personnel, assessed previously by NARDI COMPRESSORI or our authorized personnel).

If the replacement of a part requires the presence of a NARDI COMPRESSORI technician, the expenses for travel and accommodation will be

payable by the purchaser.

ASSISTANCE AND MAINTENANCE:

Spare parts must be ordered by contacting or visiting our retailers in your local area.

In cases of difficulty finding parts, contact NARDI COMPRESSORI who can provide any necessary clarifications and who will put you into contact

with the appropriate personnel.

If you need maintenance work or assistance, CONTACT THE RETAILER WHERE YOU PURCHASED THE COMPRESSOR. If you have problems

with your retailer send your request directly to:

NARDI COMPRESSORI

info@nardicompressori.com or fax to +39.0444.159122

OPERATIONS FOR INITIAL START UP:

UNPACKING AND HANDLING:

The compressor is shipped on a pallet inside a cardboard box, fastened with strapping. After unpacking it is important to check for damage during

transport and if any is identified it is important to inform the transporter and retailer as soon as possible, and in all cases not later than 7 days after

delivery.

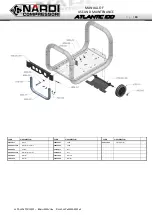

The

ATLANTIC

compressor is designed for easy handling. Its tubular frame provides convenient side handles. The compressor is

mounted on vibration dampers that limit transmission of vibrations to nearby objects. However, it must in any case be positioned on a stable

surface.

The pump unit is not resistant to constant marine corrosion.

If it comes into contact with corrosive agents it is advisable to clean the surfaces and protect them with a protective anti-corrosion spray. Always be

very careful with the electrical components.

LOCATION IN THE OPEN AIR:

To obtain breathable air it is very important to locate the compressor in an open space. It is essential that the compressor does not

intake exhaust fumes from any internal combustion engine.