PACIFIC D23

26 |

P a g e

PACIFIC D23

Nardi Compressori – www.nardicompressori.com

7.18

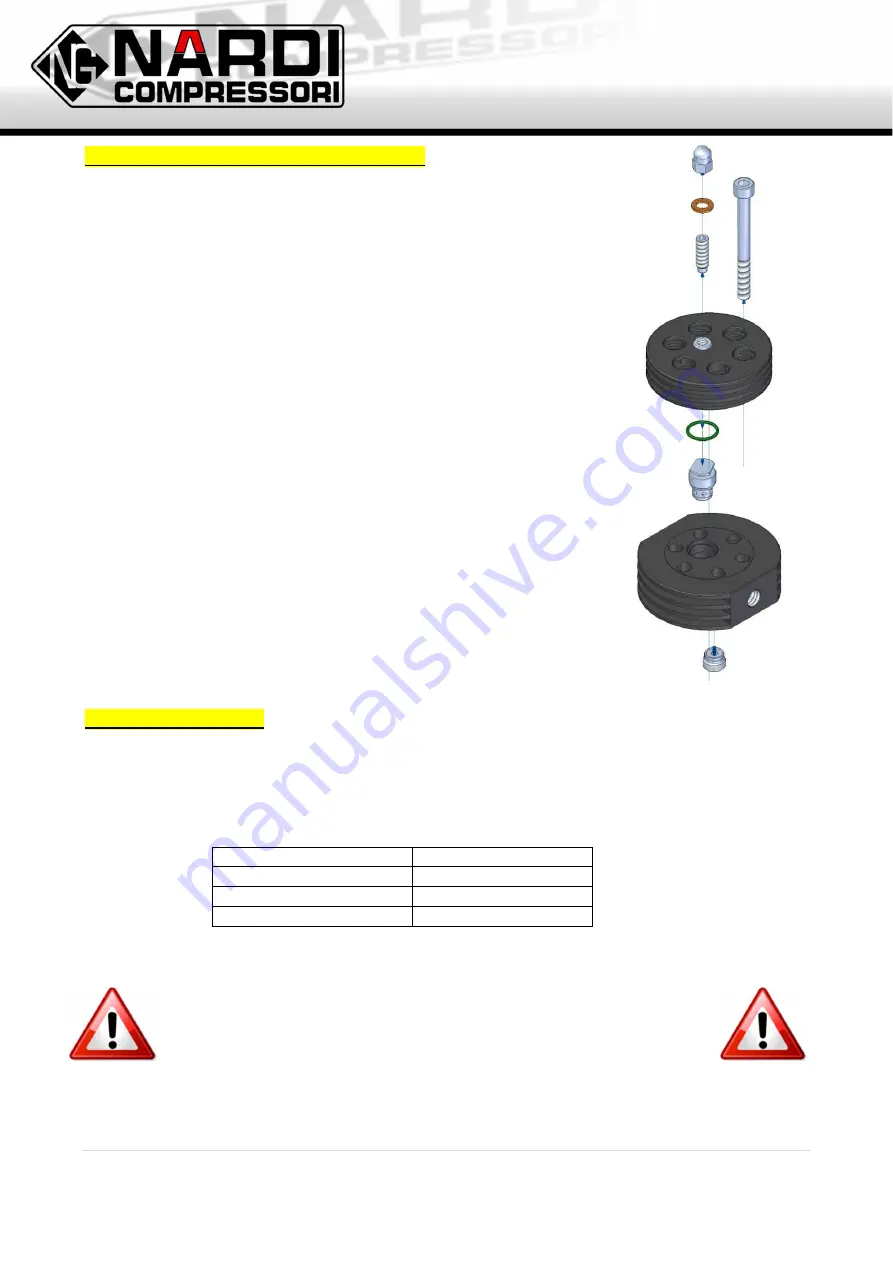

VALVE REPLACEMENT – THIRD STAGE:

The steps for replacement or cleaning of the valve are the following::

•

Disconnect the cooling hoses from the fittings.

•

Remove the screws and detach completely the head from the cylinder.

•

Put the head in a vice.

•

Unscrew the valve bodies (one of these bodies is unscrewed with a special tool

that is to be requested to Nardi Compressori).

•

Clean and remove all debris.

•

If the parts show signs of wear, change the worn parts.

•

Mount all the components following the same sequence and changing the seals.

•

On the bottom of the head there are three points that need to be engraved with a

punch after the valve is set.

•

Test the valve by blowing compressed air in the flow direction.

•

Check the O-ring seal and replace if damaged.

•

Attach the head to the cylinder.

•

Secure the cooling tubes.

7.19

SAFETY VALVES:

Queste valvole hanno un’importanza fondamentale per la sicurezza dell’operatore e del compressore.

Sono valvole tarate ad una certa pressione, che scaricano l’aria nel caso di anomalie o malfunzionamenti.

Ogni cilindro è dotato di una valvola di sicurezza, ed ogni valvola ha impostata una taratura differente:

SAFETY VALVE

MAXIMUM PRESSURE

1st STAGE

11 BAR

2nd STAGE

80 BAR

3rd STAGE

225/330 BAR

IT IS NOT ALLOWED TO CHANGE THE MAXIMUM PRESSURE CALIBRATION

OF ANY VALVE. ANY CHANGES CAN CAUSE SERIOUS DAMAGE AND

CONSEQUENT VOID OF THE WARRANTY!!