PACIFIC M35

36 |

P a g e

PACIFIC M35 REV.01-17 COD. PA201-M35-ENG

Nardi Compressori – www.nardicompressori.com

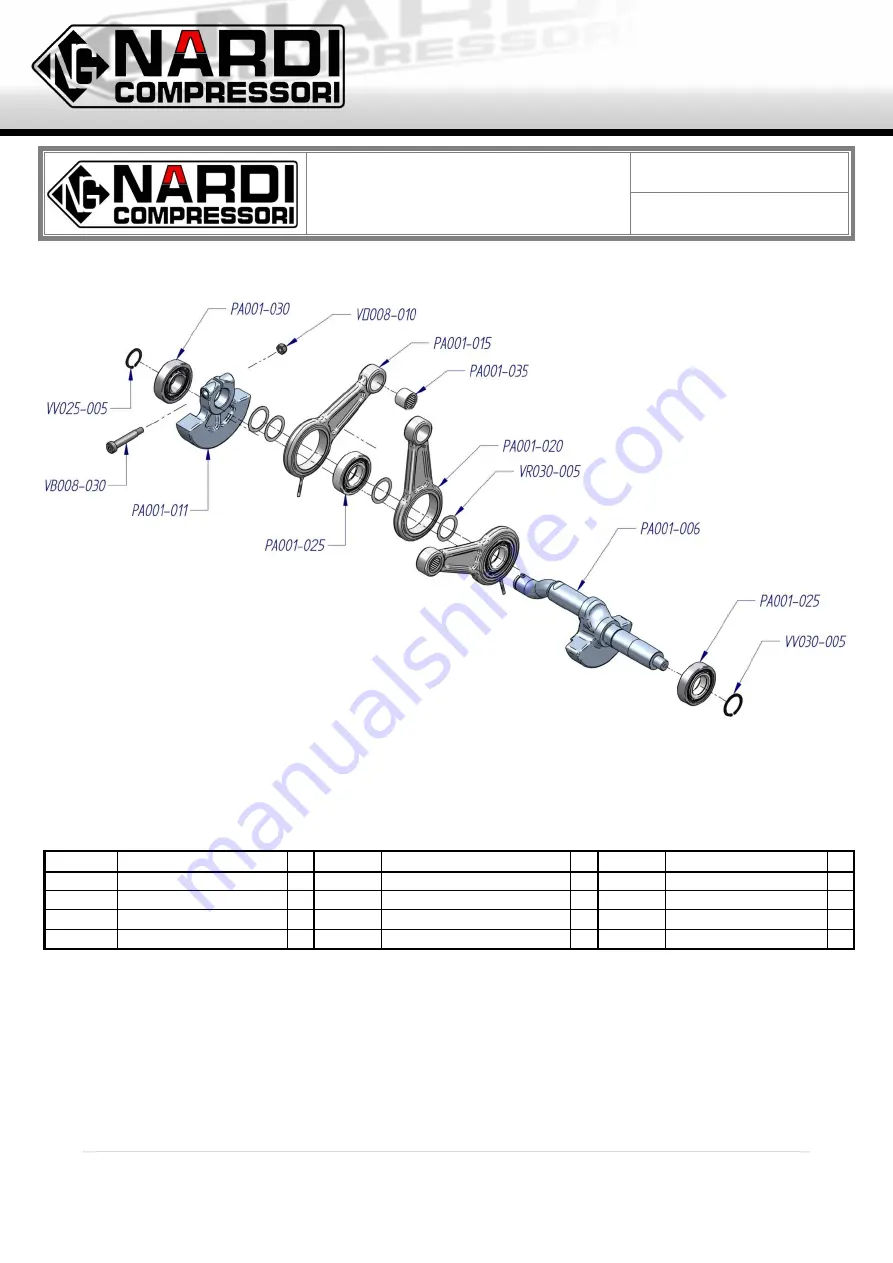

SPARE PARTS

PACIFIC 35

Driving gear

PA001-044 Rev.00

2015 Rev. 00

CODE

DESCRIPTION

CODE

DESCRIPTION

CODE

DESCRIPTION

PA001-006

Shaft

PA001-025

Roller bearing

VD008-010

Nut

PA001-011

Counterbalance

PA001-030

Roller bearing

VR030-005

Washer

PA001-015

Connecting rod with oil thrower pin

PA001-035

Roller bearing

VV025-005

Safety ring

PA001-020

Connecting rod

VB008-030

Screw

VV030-005

Safety ring