English

17

in the ON position, then by moderate depressing the rear switch button

part (1), the switch will be released and returned to the initial position, i.e.

the machine will be switched off.

Motor electronics (EBU 13-14 E)

Starting current limitation

Electronically controlled continual running secures device acceleration

without back thrust. Due to starting current limitation in the device, 16 A

protection is suffi cient.

Switching off during back thrust

During sudden drop of revolutions, for example blocking in dividing cut,

the current input in motor stops. For re-starting, the device must be first

switched off and again switched on.

Protection against re-starting

Prevent uncontrolled starting of the device after current supply cut off. For

re-starting, the device must be fi rst switched off and again switched on.

Revolutions pre-setting

Use the revolutions regulator (4) for smooth revolutions pre-setting.

1

3 500 min

-1

2

4 600 min

-1

3

6 000 min

-1

4

7 600 min

-1

5

8 900 min

-1

6

11 000 min

-1

Required number of revolutions depends on applied grinding wheel and

worked material.

Constant electronics

Constant electronics maintains revolutions during operation and idle run

near the constant. Regular operating shift is achieved.

Protection from overloading dependant on

temperature

The safety electronics switches to cooling regime when the critical tem-

perature is reached. Motor continues running at approximately 2 500 min

–1

revolutions, constant electronics is deactivated.

After cooling to approximately 10–20 s, the device is fully operational.

Heat protection for devices heated during operation, reacts adequately

sooner.

Grinding and cutting discs

Check that the label on the disc shows the permissible peripheral speed or

permissible revolution speed.

If the permissible revolution speed is given on the disc, it must not be lower

than the highest no-load speed of the grinder.

Discs with a permissible peripheral speed of 80 m/s and higher may be

used.

Test new cutting discs by letting them run for about one minute with no

load.

Unbalanced or vibrating discs should not be used and should be discarded.

Protect grinding discs from shock, impact and lubricants.

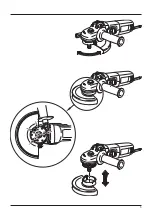

If the grinding and cutting wheels are worn down to the mark on the wheel

guard (see the arrow sign), they should be replaced with new ones. This

maintains the optimum grinding and cutting performance of the machine

(peripheral speed of the grinding and cutting wheels).

Maintenance

Vent holes (2) of the motor guard may not be covered.

Cable replacement must be carried out by a specialized service station au-

thorized correspondingly.

After ca 200 hours of operation the following activities and works

have to be carried out:

Check of brush length. The brushes shorter than 5 mm have to be replaced

for new ones.

The grinder will be stopped automatically if the brushes are worn. The

grinder is sent to the service station for maintenance.

Grease replacement in gearbox and bearings.

To preserve the class of protection, the grinder must be inspected and

checked from the point of safety.

These works must be carried out by a specialized service station au-

thorized correspondingly.

Storage

Packed appliance may be stored in dry, unheated storage place with tem-

perature not lower than -5°C.

Unpacked appliance should be stored only in dry storage place with tem-

perature not lower than +5°C with exclusion of all sudden temperature

changes.

Environmental protection

Power tools, accessories and packaging should be sorted for environmen-

tal-friendly recy.

Only for EU countries:

Do not dispose of power tools into household waste!

According to the European Directive 2002/96/EC on waste electrical and

electronic equipment and its incorporation into national law, power tools

that are no longer suitable for must be separately collected and sent for

recovery in an environmental-friendly manner.

Warranty

Our equipment is under warranty for at least 12 months with regard to ma-

terial or production faults in accordance with national legislation. In the EU

countries, the warranty period for exclusively private use is 24 months (an

invoice or delivery note is required as proof of purchase).

Damage resulting from, in particular, normal wear and tear, overloading,

improper handling, or caused by the user or other damage caused by not

following the operating instructions, or any fault acknowledged at the time

of purchase, is not covered by the warranty.

Complaints will only be acknowledged if the equipment has not been dis-

mantled before being sent back to the suppliers or to an authorised NAREX

customer support workshop. Store the operating instructions, safety notes,

spare parts list and proof of purchase in a safe place. In addition, the manu-

facturer’s current warranty conditions apply.

Information about noise level and vibrations

The values have been measured in conformity with EN 60745.

Acoustic pressure level L

pA

, acoustic power level L

wA

:

Typ

EBU 13-9

EBU 13-11

EBU 13-14 E

L

pA

91.2 dB (A)

91.2 dB (A)

91 dB (A)

L

wA

102 dB (A)

102 dB (A)

104 dB (A)

In accuracy of measurements K = 3 dB (A).

Wear noise protectors!

The weighted value of vibrations affecting hands and arms a

h

:

Typ

EBU 13-9

EBU 13-11

EBU 13-14 E

a

h

20.25 m/s

2

20.25 m/s

2

4.11 m/s

2

In accuracy of measurements K = 1.5 m/s

2

.

The emission values specified (vibration, noise) were measured in accord-

ance with the test conditions stipulated in EN 60 745 and are intended for

machine comparisons. They are also used for making preliminary estimates

regarding vibration and noise loads during operation.

The emission values specified refer to the main applications for which the

power tool is used. If the electric power tool is used for other applications,

with other tools or is not maintained sufficiently prior to operation, how-

ever, the vibration and noise load may be higher when the tool is used.

Take into account any machine idling times and downtimes to estimate

these values more accurately for a specified time period. This may signifi-

cantly reduce the load during the machine operating period.

Certificate of Conformity

We declare that the device meets requirements of the following standards

and directives.

Safety:

EN 60745-1; EN 60745-2-3

Directive 2006/42/EC

Electromagnetic compatibility:

EN 55014-1; EN 55014-2; EN 61000-3-2;EN 61000-3-3

Directive 2004/108/EC

2012

Narex s.r.o.

Chelčického 1932 Antonín Pomeisl

470 01 Česká Lípa

CEO of the company

01. 01. 2012

Changes are reserved

Summary of Contents for EBU 13-11

Page 3: ...3...

Page 4: ...4 1 2 6 5 7 9 10 12 13 14 15 18 11 14 16 8a 8b 4 3 17...

Page 5: ...5...

Page 23: ...23 1 2 a RCD RCD 3 a 4 a 5 a...

Page 24: ...o 24 a a...