English

15

Commissioning and use

Any unauthorised use might cause damage to the tool. Therefore follow

these instructions:

- Always use sharp drill bits.

- Load the tool to avoid any significant reduction of speed or stoppage.

- Always change the speed gear when the machine is idle or at the

machine slow-down at low speed, in no case during the drilling or

when the machine is otherwise loaded.

Check whether the data on the name plate correspond with the actual

power supply voltage. Tools designed for 230 V may be connected also

to 220 / 240 V.

Additional handle

For safety reasons always use the additional handle (11), firmly mounted on

the clamping neck (3). The stop bar (12) can be used to adjust the drilling

depth. By rotating the handle the position of the addition al handle and the

depth stop can be modified.

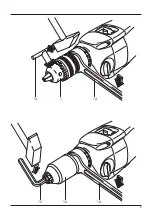

Clamping of drill bits

Chuck with ring gear

Open the chuck to allow mounting of the tool. Mount the tool on. Mount

the tool on and, using the chuck hook (13) clamp in evenly.

Quick-tightening chuck

Open the chuck to allow mounting of the tool. Mount the tool on.

Tighten the quick-tightening chuck by your hand so strongly that a “click”

sound is heard clearly. Thus the chuck will be secured automatically.

This lock will release again if you turn the sleeve contra directionally to

remove the tool.

Be careful as the chuck gets hot:

In case of longer work tasks, especially in impact drilling, the chick

might get very hot. In this case you are recommended to wear

protective gloves.

Switching on and off

By pressing the switch button (7) the machine activates and releasing the

button stops it.

Controls

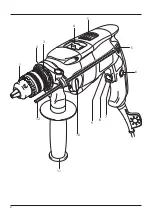

1 ............ Chuck with ring gear

2 ............ Spots on spindle

3 ............ Clamping neck

4 ............ Lever for impact shifting

5 ............ Air vents

6 ............ Latching pin

7 ............ Switch / controller

8 ............ Speed pre-selection wheel

9 ............ Alteration switch lever

10 .......... Gear-shifting lever

11 .......... Additional handle

12 .......... Stop bar

13 .......... Chuck hook

14 .......... Spanner

15 .......... Socket screw wrench

16 .......... Quick-tightening chuck

The displayed or described accessories need not be included in the delivery

package.

Double insulation

To ensure maximum safety of the user, our tools are designed and built to

satisfy applicable European standards (EN standards). Tools with double

insulation are marked by the international symbol of a double square.

These tools must not be grounded and a two-wire cable is sufficient to

supply them with power. Tools are shielded in accordance with EN 50114.

Use

The machine is intended drilling in wood, metal, ceramic and plastic.

Machines with electronic control and right/left rotation are also suitable

for screwing and thread cutting ( Only for soft screwdriving applications).

In addition, the machine is designed for impact drilling in brick, concrete

and stone as well as for drilling in wood, metal, ceramics and plastics.

Machines with electronic control and right/left rotation are also suitable for

screwing and thread-cutting.

The user alone is responsible for any liabilities caused by usage other than

intended.

Technical data

Impact drill

Type

EVP 13 G-2H3

EVP 13 G-2A

Supply voltage

230–240 V

230–240 V

Power frequency

50–60 Hz

50–60 Hz

Power input

760 W

760 W

Speed under load

1st speed gear

0–600 min

-1

0–600 min

-1

2nd speed gear

0–1 750 min

-1

0–1 750 min

-1

Idle speed

1st speed gear

0–1 100 min

-1

0–1 100 min

-1

2nd speed gear

0–3 050 min

-1

0–3 050 min

-1

Number of impacts

1st speed gear

0–22 000 min

-1

0–22 000 min

-1

2nd speed gear

0–61 000 min

-1

0–61 000 min

-1

Speed pre-selection

ü

ü

Right-left turning

ü

ü

Extent of chuck dia.

1.5–13 mm

1.5–13 mm

Thread on spindle

1/2“-20 UNF

1/2“-20 UNF

Quick-tightening chuck Auto-Lock

û

ü

Drilling dia. max

into steel

13 mm

13 mm

into aluminium

25 mm

25 mm

into wood

45 mm

45 mm

into concrete

20 mm

20 mm

Clamping neck dia.

43 mm

43 mm

Weight

2.1 kg 2.2 kg

Protection class

II /

II /

Summary of Contents for EVP 13 G-2A

Page 3: ...3...

Page 4: ...4 1 2 3 4 5 5 6 7 8 9 10 11 12...

Page 5: ...5 1 13 14 15 16 14...

Page 22: ...o 22 1 2 a RCD RCD 3 a 4 a 5 a a...

Page 34: ...34...

Page 35: ...35...