Summary of Contents for PC16

Page 2: ...Thank you for choosing our machines www nargesa com...

Page 21: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B20 A1 List of parts...

Page 22: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B21...

Page 23: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B22...

Page 24: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B23...

Page 25: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B24...

Page 26: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B25 A2 Material cylinder...

Page 27: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B26...

Page 28: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B27 A3 Cylinder...

Page 29: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B28...

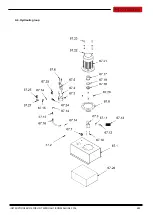

Page 30: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B29 A4 Hydraulic group...

Page 31: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B30...

Page 32: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B31...

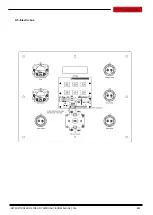

Page 33: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B32 A5 Electric box...

Page 34: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B33...

Page 35: ...INSTRUCTIONS BOOK FOR HOT WROUGHT IRON MACHINE PC16 B34 A6 Electric map...