26

Gas Furnace

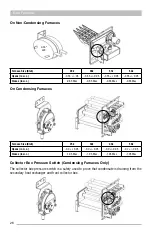

On Non-Condensing Furnaces

Furnace Size (Btuh)

28k

38k

51k

64k

Opens (in w.c.)

-0.55 +/- .05

-0.55 +/- 0.05

-0.55 +/- 0.05

-.055 +/- 0.05

Closes (in w.c.)

-0.65 Max

-0.65 Max

-0.65 Max

-0.65 Max

On Condensing Furnaces

Furnace Size (Btuh)

25k

32k

43k

50k

Opens (in w.c.)

-0.9 +/- 0.05

-0.9 +/- 0.05

-0.9 +/- 0.05

-0.7 +/- 0.05

Closes (in w.c.)

-1.05 Max

-1.05 Max

-1.05 Max

-1.05 Max

Collector Box Pressure Switch (Condensing Furnaces Only)

The collector box pressure switch is a safety used to prove that condensate is draining from the

secondary heat exchanger and front collector box.

0.55”

WC

On Condensing furnaces

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.9 +/- .05

-.9 +/- .05

-.9 +/- .05

-.7 +/- .05

Closes ("wc)

-1.05 Max

-1.05 Max

-1.05 Max

-1.05 Max

Collector Box Pressure Switch (Condensing Furnaces Only)

The collector box pressure switch is a safety used to prove that condensate is draining from the secondary heat exchanger

and front collector box.

The Pressure Switch is normally open

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.2 +/- .05

-.3 +/- .05

-.3 +/- .05

-.6 +/- .05

Closes ("wc)

-.35 Max

-.45 Max

-.45 Max

-.75 Max

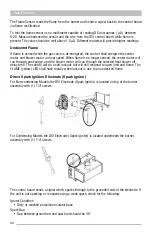

To check the pressure switch, first prove that the inducer assembly is pulling adequate static pressure at the pressure

switch tubing using a manometer.

To prove the pressure switch has welded closed, use an ohmmeter, and verify there is continuity across the terminals when

disconnected from the pressure switch tubing.

If the unit is experiencing faults with the pressure switch check for the following:

•

Proper venter motor operation with no obstructions in the housing.

•

Inspect the tubing for blockages, cracks, or other damage.

•

Check the ports on the venter housing for blockage with corrosion or debris.

•

Verify that the venter tubing is installed properly on the pressure switch (non-condensing models) (gray – negative

On Condensing furnaces

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.9 +/- .05

-.9 +/- .05

-.9 +/- .05

-.7 +/- .05

Closes ("wc)

-1.05 Max

-1.05 Max

-1.05 Max

-1.05 Max

Collector Box Pressure Switch (Condensing Furnaces Only)

The collector box pressure switch is a safety used to prove that condensate is draining from the secondary heat exchanger

and front collector box.

The Pressure Switch is normally open

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.2 +/- .05

-.3 +/- .05

-.3 +/- .05

-.6 +/- .05

Closes ("wc)

-.35 Max

-.45 Max

-.45 Max

-.75 Max

To check the pressure switch, first prove that the inducer assembly is pulling adequate static pressure at the pressure

switch tubing using a manometer.

To prove the pressure switch has welded closed, use an ohmmeter, and verify there is continuity across the terminals when

disconnected from the pressure switch tubing.

If the unit is experiencing faults with the pressure switch check for the following:

•

Proper venter motor operation with no obstructions in the housing.

•

Inspect the tubing for blockages, cracks, or other damage.

•

Check the ports on the venter housing for blockage with corrosion or debris.

•

Verify that the venter tubing is installed properly on the pressure switch (non-condensing models) (gray – negative

0.55”

WC

On Condensing furnaces

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.9 +/- .05

-.9 +/- .05

-.9 +/- .05

-.7 +/- .05

Closes ("wc)

-1.05 Max

-1.05 Max

-1.05 Max

-1.05 Max

Collector Box Pressure Switch (Condensing Furnaces Only)

The collector box pressure switch is a safety used to prove that condensate is draining from the secondary heat exchanger

and front collector box.

The Pressure Switch is normally open

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.2 +/- .05

-.3 +/- .05

-.3 +/- .05

-.6 +/- .05

Closes ("wc)

-.35 Max

-.45 Max

-.45 Max

-.75 Max

To check the pressure switch, first prove that the inducer assembly is pulling adequate static pressure at the pressure

switch tubing using a manometer.

To prove the pressure switch has welded closed, use an ohmmeter, and verify there is continuity across the terminals when

disconnected from the pressure switch tubing.

If the unit is experiencing faults with the pressure switch check for the following:

•

Proper venter motor operation with no obstructions in the housing.

•

Inspect the tubing for blockages, cracks, or other damage.

•

Check the ports on the venter housing for blockage with corrosion or debris.

•

Verify that the venter tubing is installed properly on the pressure switch (non-condensing models) (gray – negative

On Condensing furnaces

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.9 +/- .05

-.9 +/- .05

-.9 +/- .05

-.7 +/- .05

Closes ("wc)

-1.05 Max

-1.05 Max

-1.05 Max

-1.05 Max

Collector Box Pressure Switch (Condensing Furnaces Only)

The collector box pressure switch is a safety used to prove that condensate is draining from the secondary heat exchanger

and front collector box.

The Pressure Switch is normally open

BTU Size

25K

32K

43K

50K

Opens ("wc)

-.2 +/- .05

-.3 +/- .05

-.3 +/- .05

-.6 +/- .05

Closes ("wc)

-.35 Max

-.45 Max

-.45 Max

-.75 Max

To check the pressure switch, first prove that the inducer assembly is pulling adequate static pressure at the pressure

switch tubing using a manometer.

To prove the pressure switch has welded closed, use an ohmmeter, and verify there is continuity across the terminals when

disconnected from the pressure switch tubing.

If the unit is experiencing faults with the pressure switch check for the following:

•

Proper venter motor operation with no obstructions in the housing.

•

Inspect the tubing for blockages, cracks, or other damage.

•

Check the ports on the venter housing for blockage with corrosion or debris.

•

Verify that the venter tubing is installed properly on the pressure switch (non-condensing models) (gray – negative

Summary of Contents for CPG41838-U

Page 2: ...2...

Page 5: ...5 Unit Dimensions Original R22 with Gas Heat A B Series 43...

Page 6: ...6 Original R22 with Electric Heat A B Series Unit Dimensions...

Page 7: ...7 Unit Dimensions Original R410A with Gas Heat B C D E Series...

Page 8: ...8 Unit Dimensions Original R410A with Electric Heat B C D E Series...

Page 9: ...9 Unit Dimensions U Series R410A 80 Gas Heat...

Page 10: ...10 Unit Dimensions U Series R410A up to 95 Gas Heat...

Page 11: ...11 Unit Dimensions U Series R410A Electric Heat...

Page 19: ...19 Gas Furnace 3 Remove the 11 screws 4 Remove the front furnace baffle...

Page 46: ...46 Chassis Cooling Section...

Page 79: ...79...