Machine Maintenance

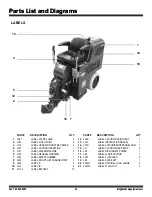

FIG. AC

LEAK MAINTENANCE

All

fi

ttings on this machine are O-ring style.

1. Disconnect machine from power.

2. If a leak is detected, tighten

fi

tting with the proper wrench size. DO NOT over

tighten. Over tightening could damage O-rings.

CHECK OIL LEVEL

1. Remove Breather Dip Stick (G).

2. Check to see that Hydraulic Fluid is visible on Dip Stick.

OR

1. Remove Filler plug (H).

2. Oil should be visible 5 cm (2”) below hole.

3. Reinsert

plug.

OIL CHANGE OUT

1. Disconnect machine from power (charger or battery).

2. Drain

fl

uid by removing the drain plug from side of tank (I).

3. Replace drain plug (I).

4. Remove

fi

ller plug (H).

5. Add oil into the

fi

ller plug hole until visual 2” below hole.

HOSE CHANGE OUT/REMOVAL

1. Disconnect machine from power.

2. Remove

hood.

3. Using proper wrench size, remove hose from

fi

tting.

4. When replacing, make sure O-ring is properly seated on hose

fi

tting.

WHEEL MOTOR CHANGE OUT

1. Disconnect machine from power.

2. Block up machine to remove wheel. See wheel changing on page 28.

3. Remove

wheel.

4. Remove oil lines from wheel motor. A small amount of oil will run out of the lines.

Drain into a container. Wipe up spills immediately.

5. Remove four 1/2” wheel motor securing nuts.

6. Pull out on wheel motor to remove.

FOOT PEG REMOVAL/REPLACE

1. Insert a socket wrench into foot peg and secure bolt head.

2. Remove

nut.

3. Remove bolt and foot peg.

4. Replace foot peg before operating machine. DO NOT use machine without foot

pegs.

FIG. AD

Fax: 763-535-8255

info@nationalequipment.com

27

G

H

I

CAUTION:

THIS UNIT CONTAINS 7 ½ GALLONS OF FLUID. MAKE SURE YOU

HAVE THE PROPER AMOUNT OF CONTAINERS CATCH FLUID.