Machine Maintenance

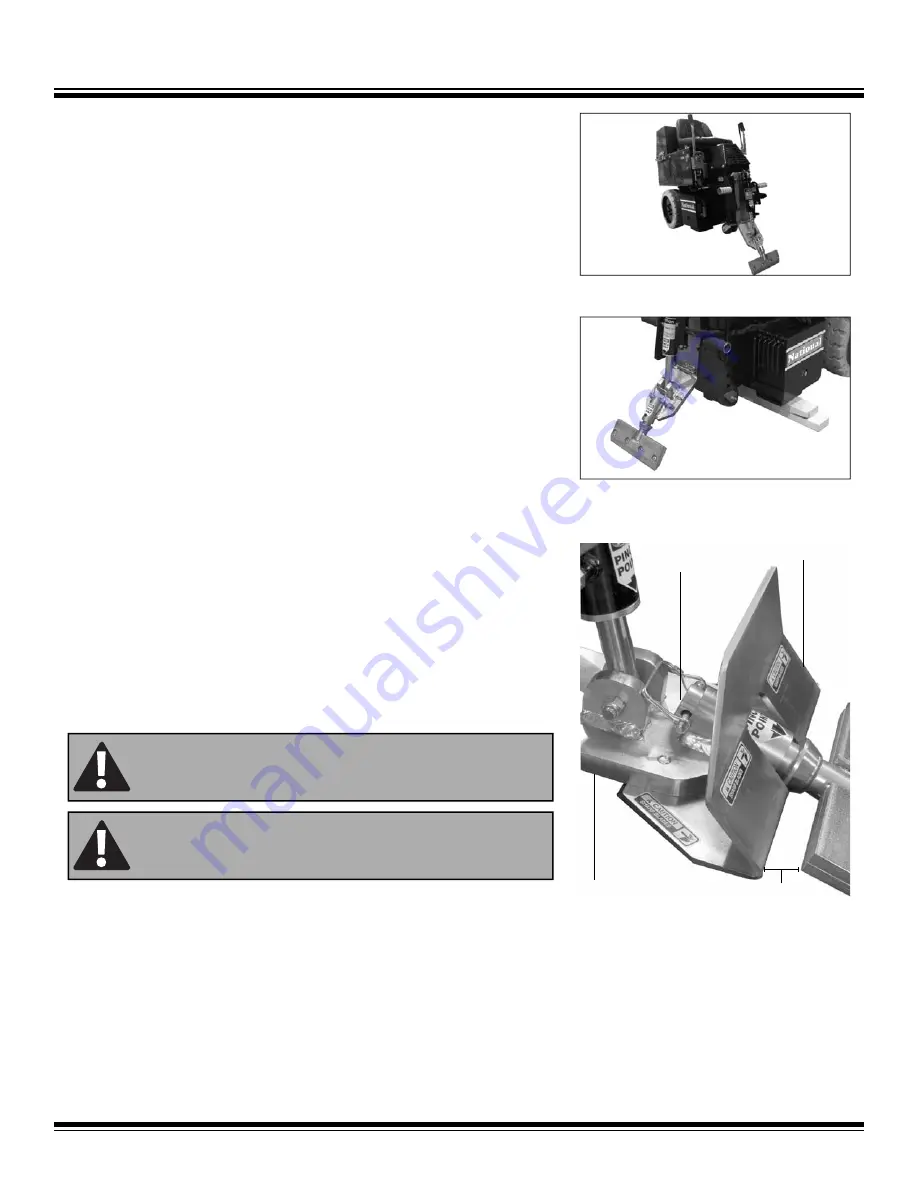

FIG. AG

CASTER WHEEL MAINTENANCE

1. Keep clean and free of debris, make sure it can move freely.

2. Give a shot of grease in grease

fi

tting on caster every six months to keep moving

freely.

3. To remove caster, machine will need to be raised. Push the cylinder lift lever for-

ward to lower and adjust the angle of the cutting head to jack up the machine

(Figure AG). Block up machine (Figure AH). Remove four bolts, pull caster off and

clean/replace as needed.

4. Replace

caster.

5. Replace

and

fi

rmly tighten the four bolts.

6. Lower the machine.

SEAT REPLACEMENT

1. Remove four (4) hexhead screws on each side of the hood (4 times).

2. Slightly raise seat plate & unplug wire harness.

3. Lift hood off.

4. Remove

seat.

5. To replace seat, set seat on top of hood.

6. Replace the four 3/8” x 16” x 3/4” hexhead screws from underneath the hood.

7. Firmly

tighten.

8. Reconnect back-up beeper and seat switch wires.

9. Replace hood and screws.

DEBRIS DEFLECTOR (FIGURE AI)

1. Place the debris de

fl

ector under the lower cutting head support and align with the

two threaded holes.

2. Firmly secure debris de

fl

ector under the cutting head with the two bolts supplied.

FIG. AH

Fax: 763-535-8255

info@nationalequipment.com

29

WARNING:

DO NOT ALTER A SWITCH OR LEVER. DO NOT DEFEAT A

SAFETY DEVICE.

WARNING:

THE BACK-UP BEEPER IS ON THE MACHINE FOR SAFETY. IT IS

IMPORTANT TO KEEP IT IN GOOD WORKING CONDITION. FAILURE TO DO SO

COULD CAUSE BODILY INJURY.

FIG. AI

1” Clearance

Lower Cutting

Head Support

Insert & Secure

Cutting Head

Debris De

fl

ector