Safety

7

HYDRAULIC SAFETY

Maintaining a Safe Work Environment

Establishing a safe work environment in and around your hydraulic equipment is extremely important. The easiest and most effective way to

avoid problems is to make sure associates understand their equipment, know how to operate the machines safely, and recognize the dangers if

handled carelessly. A few things to be aware of are:

• Pressure:

Hydraulic fluid under pressure is dangerous and can cause serious injury. Never look for a leak when unit is under pressure.

Using your hand could cause serious injury. A few common ways to encounter hydraulic fluid under pressure include:

▪

Pinhole: Fluid under pressure can cause serious injury. It can be almost invisible escaping from a pinhole, and it can pierce the skin

into the body.

▪

Leak: Keep fittings and hoses tight. Only check and service when not under pressure. Leaking hydraulic fluid is hazardous; in addition

to making workplace floors slippery and dangerous, it also contaminates the environment. Before cleaning an oil spill, always check

EPA, state, and local regulations.

▪

Burst: Whether due to improper selection or damage, a ruptured hose can cause injury. If it bursts, a worker can be burned, cut,

injected, or may slip and fall.

▪

Coupling Blow-Off: If the assembly is not properly made or installed, the coupling could come off and hit or spray a worker, possibly

resulting in serious injury. Never operate machine without guards.

• Flammability:

When ignited, some hydraulic fluids can cause fires and/or explode.With the exception of those comprised primarily of

water, all hydraulic fluid is flammable (including many “fire-resistant” hydraulic fluids) when exposed to the proper conditions. Leaking pres-

surized hydraulic fluids may develop a mist or fine spray that can flash or explode upon contact with a source of ignition. These explosions

can be very severe and could result in serious injury or death. Precautions should be taken to eliminate all ignition sources from contact

with escaping fluids, sprays or mists resulting from hydraulic failures. Sources of ignition could be electrical discharges (sparks), open

flames, extremely high temperatures, sparks caused by metal -to -metal contact, etc.

• Mechanical:

Hydraulic fluid creates movement, which means some equipment may move. Observe surroundings and equipment at all

times.

• Moisture:

Do not use in wet or high moisture conditions.

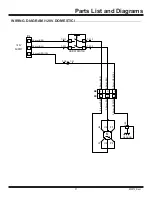

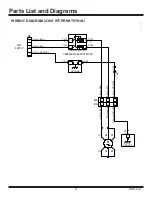

• Electrical:

Faulty wiring can be an electrical hazard. A regular preventive maintenance program should always include a wiring check. If

applicable, disconnect battery before serving.

• Temperature:

Because this machine operates at a relatively low pressure, overheating is not common. If surface of tank becomes too hot

to touch by hand (above 130ºF or 55°C), shut off machine and allow it to cool.

Hydraulic Fluid

Only use Texaco Rando 46 Hydraulic Oil or compatible fluid like ISO or AW #46 from a brand name manufacturer. Non-compatible fluids could

cause damage to unit or serious injury.

CAUTION:

NEVER USE YOUR HANDS TO CHECK FOR LEAKS OVER HOSE OR HYDRAULIC CONNECTIONS. USE A PIECE OF CARD-

BOARD TO LOCATE A PRESSURIZED LEAK. FOR LOW PRESSURE LEAKS (DRIPS), USE A RAG TO CLEAN THE AREA AND DETERMINE

WHERE THE LEAK ORIGINATES.

DANGER:

DO NOT TOUCH A PRESSURIZED HYDRAULIC HOSE ASSEMBLY WITH ANY PART OF THE BODY. IF FLUID PUNCTURES

THE SKIN, EVEN IF NO PAIN IS FELT, A SERIOUS EMERGENCY EXISTS. OBTAIN MEDICAL ASSISTANCE IMMEDIATELY. FAILURE TO DO

SO COULD RESULT IN LOSS OF THE INJURED BODY PART OR DEATH.

7

402972_RevJ