© National Instruments

|

B-1

B

Internal Power Cables

This appendix lists the internal power cables for the ATE Core Configurations.

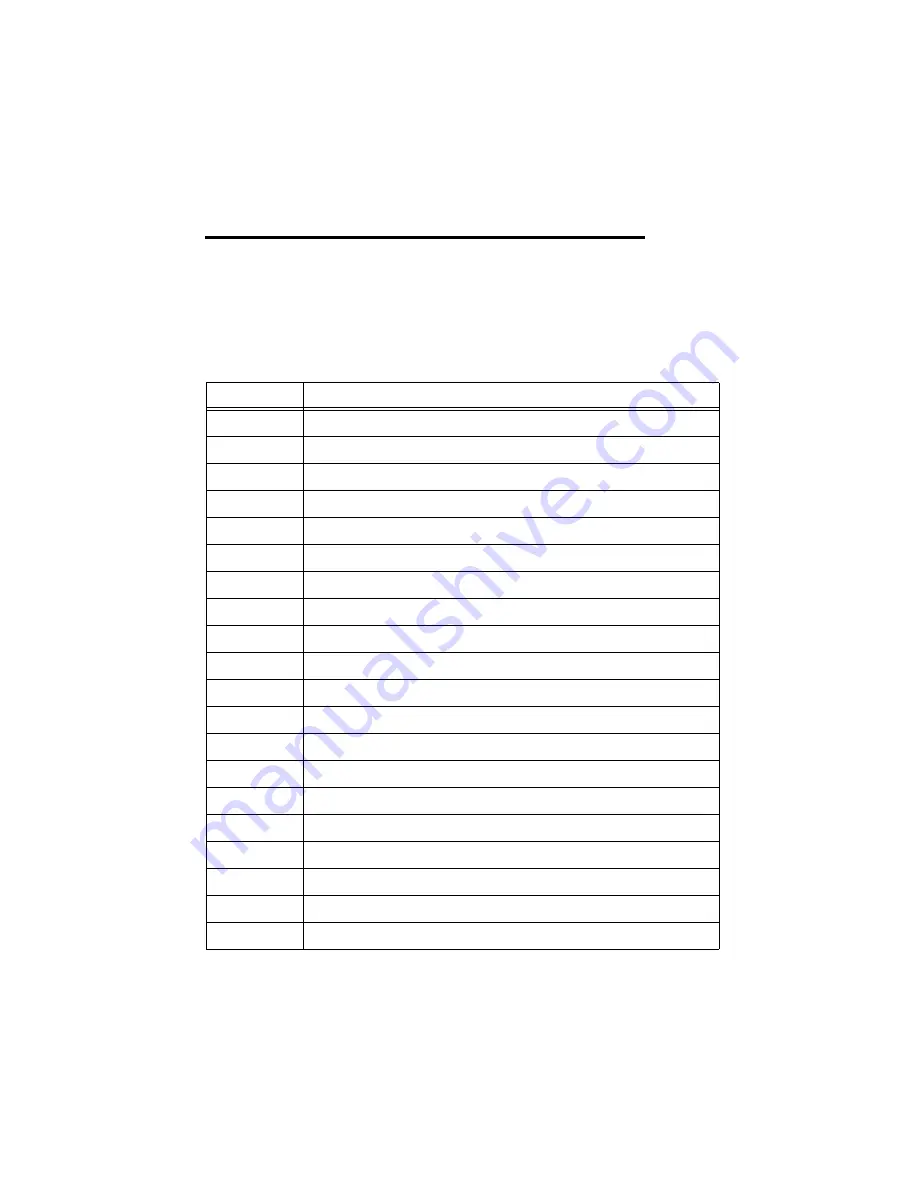

Table B-1.

RMX-10011 Internal Power Cables

Part Number

Description

785707-01

AC, IEC C20 to NEMA 5-20R, 125 V, 16 A, 0.25 m (US)

785708-01

AC, IEC C19 to NEMA 5-20P, 125 V, 16 A, 2.5 m (US)

785709-01

AC, IEC C20 to IEC C13, 240 V, 10 A (EU), 16 A (UL), 1.5 m (US, EU)

785709-02

AC, IEC C20 to IEC C13, 240 V, 10 A (EU), 16 A (UL), 2.5 m (US, EU)

785710-01

AC, IEC C20 to IEC C19, 240 V, 16 A, 1.5 m (US, EU, China, Korea)

785710-0112

AC, IEC C20 to IEC C19, 240 V, 16 A, 1.5 m (Japan)

785710-02

AC, IEC C20 to IEC C19, 240 V, 16 A, 2.5 m (US, EU, China, Korea)

785710-0212

AC, IEC C20 to IEC C19, 240 V, 16 A, 2.5 m (Japan)

785711-01

AC, IEC C20 to Bare Wire, 240 V, 16 A, 1.5 m (US, EU, China, Korea)

785711-0112

AC, IEC C20 to Bare Wire, 240 V, 16 A, 1.5 m (Japan)

785711-02

AC, IEC C20 to Bare Wire, 240 V, 16 A, 2.5 m (US, EU, China, Korea)

785711-0212

AC, IEC C20 to Bare Wire, 240 V, 16 A, 2.5 m (Japan)

785712-01

AC, IEC C14 to Bare Wire, 240 V, 10 A, 1.5 m (EU, China, Korea)

785712-02

AC, IEC C14 to Bare Wire, 240 V, 10 A, 2.5 m (EU, China, Korea)

785713-01

AC, IEC C14 to IEC C13, 240 V, 10 A, 1.5 m (US)

785713-0112

AC, IEC C14 to IEC C13, 240 V, 10 A, 1.5 m (Japan)

785713-02

AC, IEC C14 to IEC C13, 240 V, 10 A, 2.5 m (US)

785713-0401

AC, IEC C14 to IEC C13, 240V, 10 A, 1.5 m (EU, China, Korea)

785713-0402

AC, IEC C14 to IEC C13, 240V, 10 A, 2.5 m (EU, China, Korea)

785727-01

AC, NEMA 5-20P to Bare Wire, 125 V, 20 A, 1.5m (US)