Using the Internal Real-Time Clock

The system clock of the cRIO-9074XT is synchronized with the internal high-precision real-

time clock at startup. This synchronization provides timestamp data to the controller. You can

also use the internal real-time clock to correct drift of the system clock. Refer to the

Real-Time Clock Specifications

for the accuracy specifications of the real-time clock.

Using the SMB Connector for Digital I/O

(cRIO-9074 only)

You can use the SMB connector of the cRIO-9074XT to connect digital devices to the

controller. For example, if you connect the pulse-per-second output of a GPS device to the

SMB connector of the cRIO-9074XT, you can use the GPS device to correct for drift of the

system clock.

For software that supports GPS drift-correction and other digital I/O through the SMB

connector, go to

and enter the Info Code

criosmb

.

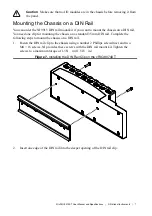

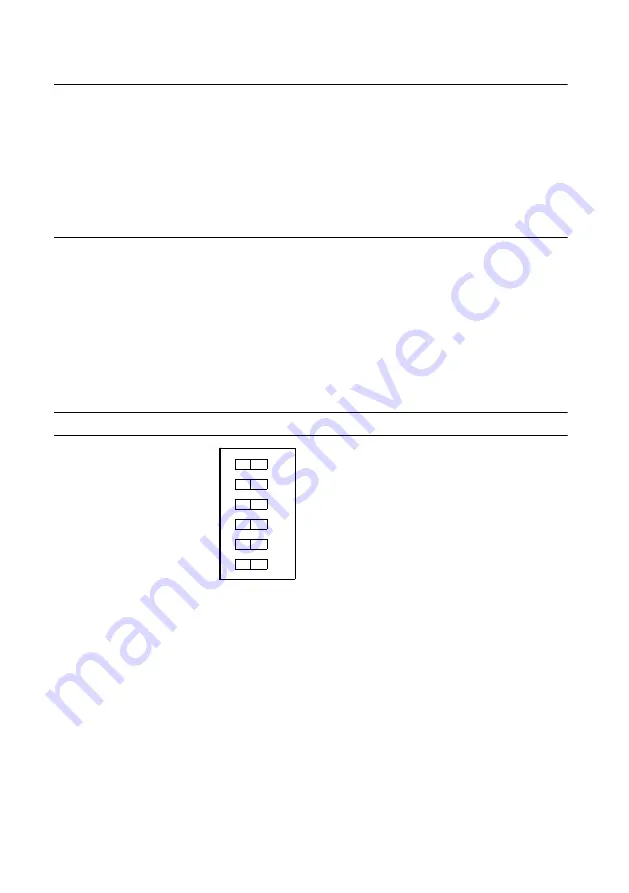

Configuring DIP Switches

Figure 13.

DIP Switches

1

6

5

4

3

2

SAFE MODE

CONSOLE OUT

IP RESET

NO APP

USER1

NO FPGA

OFF

All of the DIP switches are in the OFF position when the chassis is shipped from National

Instruments.

SAFE MODE Switch

The position of the SAFE MODE switch determines whether the embedded LabVIEW Real-

Time engine launches at startup. If the switch is in the OFF position, the LabVIEW Real-Time

engine launches. Keep this switch in the OFF position during normal operation. If the switch is

in the ON position at startup, the cRIO-9074XT launches only the essential services required

for updating its configuration and installing software. The LabVIEW Real-Time engine does

not launch.

If the software on the controller is corrupted, you must put the controller into safe mode and

reformat the controller drive. You can put the controller into safe mode by powering it up

either with the SAFE MODE switch in the ON position or with no software installed on the

NI cRIO-9074XT User Manual and Specifications

|

© National Instruments

|

13

Summary of Contents for NI cRIO-9074XT

Page 1: ...cRIO 9074...