Initialization software uses the configuration information specific to each adjacent peripheral

module to evaluate local bus compatibility.

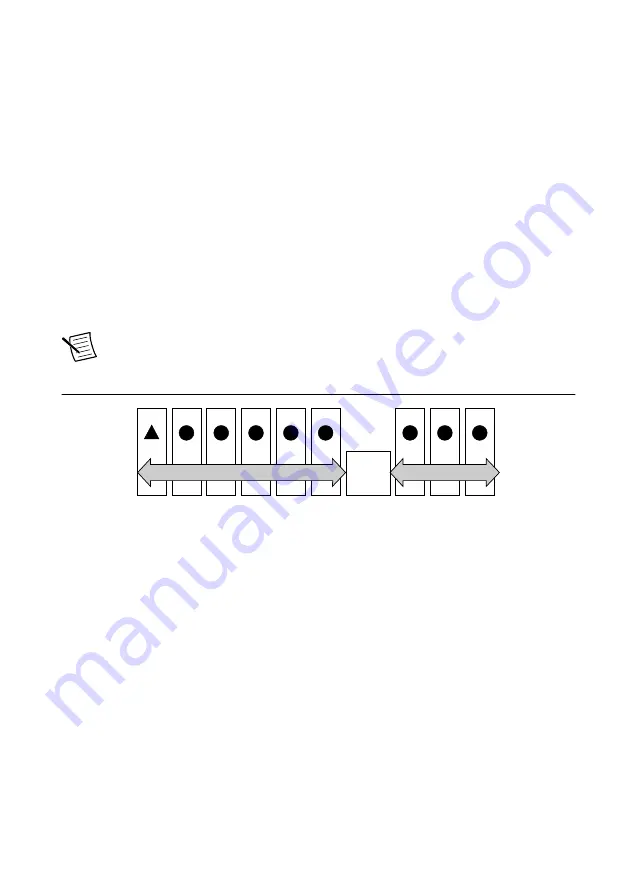

PXI Trigger Bus

All slots on the same PXI bus segment share eight PXI trigger lines. You can use these trigger

lines in a variety of ways. For example, you can use triggers to synchronize the operation of

several different PXI peripheral modules. Modules can pass triggers to one another on the

lines, allowing precisely timed responses to asynchronous external events the system is

monitoring or controlling.

The PXI trigger lines from adjacent PXI trigger bus segments can be routed in either direction

across the PXI trigger bridges through buffers. This allows you to send trigger signals to, and

receive trigger signals from, every slot in the chassis. Static trigger routing (user-specified line

and directional assignments) can be configured through Measurement & Automation Explorer

(MAX). Dynamic routing of triggers (automatic line assignments) is supported through certain

National Instruments drivers like NI-DAQmx.

Note

Although any trigger line may be routed in either direction, it cannot be

routed in more than one direction at a time.

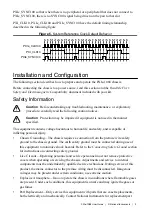

Figure 4. PXI Trigger Bus Connectivity Diagram

H

H

H

7

8

9

H

H

H

H

1

2

3

4

5

6

PXI

Trigger

Bridge #1

PXI Trigger Bus #1

PXI Trigger Bus #2

H

System Reference Clock

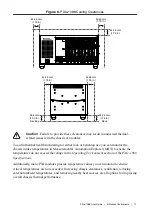

The PXIe-1088 chassis supplies PXI_CLK10, PXIe_CLK100 and PXIe_SYNC100 to every

peripheral slot with an independent driver for each signal.

An independent buffer (having a source impedance matched to the backplane and a skew of

less than 250 ps between slots) drives PXI_CLK10 to each peripheral slot. You can use this

common reference clock signal to synchronize multiple modules in a measurement or control

system.

An independent buffer drives PXIe_CLK100 to each peripheral slot. These clocks are matched

in skew to less than 100 ps. The differential pair must be terminated on the peripheral with

LVPECL termination for the buffer to drive PXIe_CLK100 so that when there is no peripheral

or a peripheral that does not connect to PXIe_CLK100, there is no clock being driven on the

pair to that slot.

An independent buffer drives PXIe_SYNC100 to each peripheral slot. The differential pair

must be terminated on the peripheral with LVPECL termination for the buffer to drive

8

|

ni.com

|

PXIe-1088 User Guide