NI UMI-7774/72 User Guide and Specifications

12

ni.com

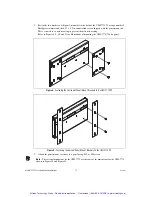

1.

Fasten the two brackets of the panel-mount kit to the back of the UMI-7774/72 using a number 2

Phillips screwdriver and the 8-32

.25 in. countersink screws shipped with the panel-mount kit.

These screws have a nylon coating to prevent them from loosening.

Refer to Figures 8, 9, 10, and 11 for illustrations of mounting the UMI-7774/72 on a panel.

Figure 8.

Fastening the Horizontal Panel-Mount Brackets to the UMI-7774/72

Figure 9.

Fastening the Vertical Panel-Mount Brackets to the UMI-7774/72

2.

Attach the panel-mount accessory to a panel using 8-32 or M4 screws.

Note

The external dimensions for the UMI-7772 are the same as the dimensions for the UMI-7774,

shown in Figure 10 and Figure 11.

NA

TIO

NA

L

INS

TR

UM

EN

TS

NA

TIONA

L

INS

TR

UM

EN

TS

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com