INSTALLATION

Procedures for installing Recordall Compound Series meters are essentially the same for all meter sizes Any special

instructions required for the installation or connection of accessory devices such as AMR/AMI technologies or strainers is

provided in the literature for those devices

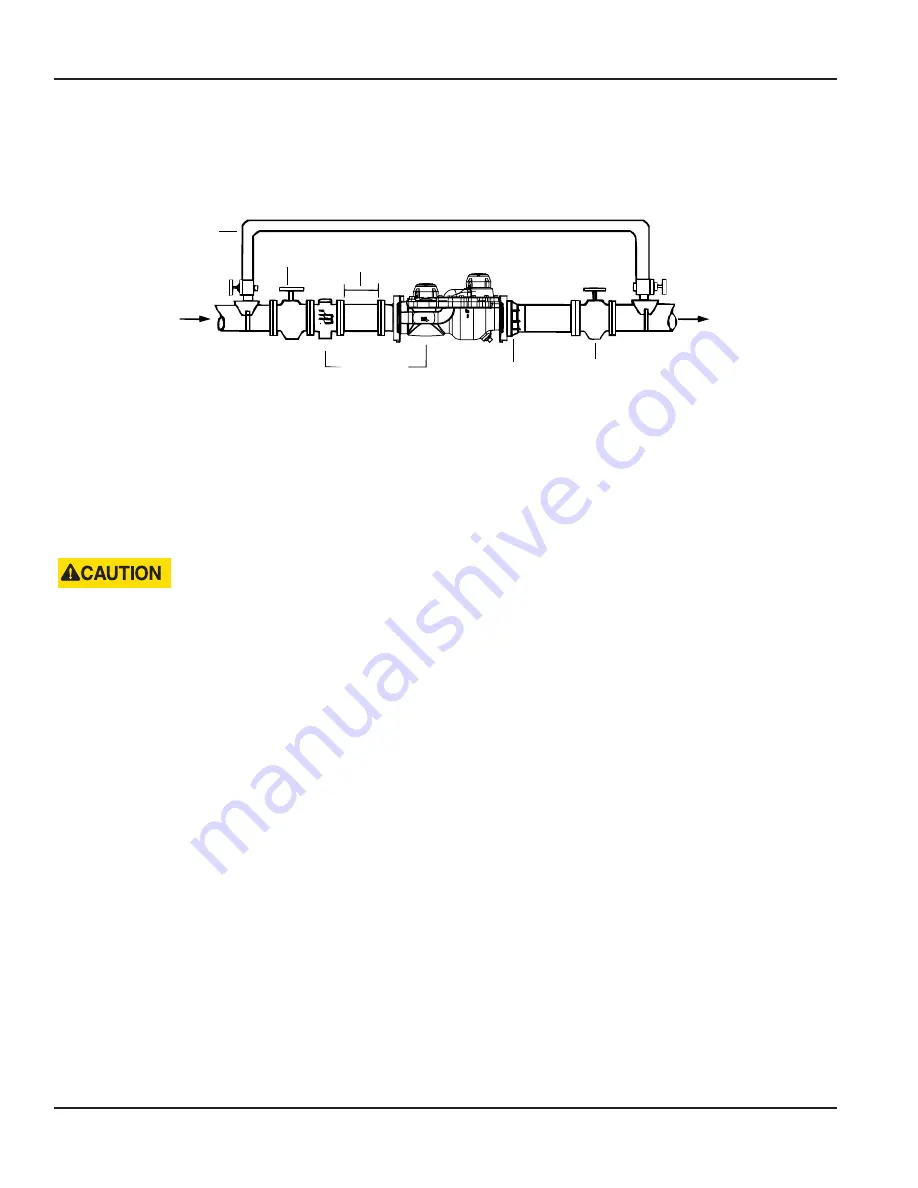

shows a recommended meter installation

By-Pass

(Permanent or

Temporary)

Upstream

Valve

(Open)

Minimum of Five

Diameters of

Straight Pipe

Badger Plate

Strainer and

Compound Meter

By-Pass

(Permanent or

Temporary)

Coupling

Adaptor

Shut-Off

Valve

Downstream

Figure 1: Recommended meter installation

Preinstallation Considerations

Before proceeding any further with the installation, first read the instructions in the paragraphs immediately following to

become familiar with the requirements and procedures involved

NOTE:

N

The Recordall Compound Series meters are designed for operation in HORIZONTAL piping arrangements

• Be sure that the meter flow range and size of the meter coincide with the intended service and demand for water

THE LIFE OF THE COMPOUND METER WILL BE CURTAILED IF OPERATED AT FLOW RATES HIGHER THAN SPECIFIED.

• The meters are designed for use in cold water service (up to 120° F or 27° C) within the applicable flow requirements

for compound meters For use with water at higher temperatures, consult your Badger Meter representative or nearest

Badger Meter regional sales office

• If solid material is present in the water to be metered, a strainer must be installed in the service piping upstream of the

meter The strainer, in addition to protecting the meter from debris in the line, minimizes the effect of velocity profile

distortions or turbulence caused by changes in pipe direction or valving resulting in more accurate registration Contact

your Badger Meter representative for information on Recordall Plate Strainers

• Avoid locating the meter in close quarters Allow sufficient space to permit access for meter reading, testing,

and maintenance

• Because of the need to test large meters periodically to verify their performance, it is recommended that a bypass system

be incorporated into the piping arrangement This will also provide a means of performing periodic cleanout and routine

maintenance without interrupting service to the customer A test port is incorporated in the meter housing and can be

used for field accuracy testing

• The Recordall Compound Series meter is accuracy and pressure tested prior to shipment, therefore no field adjustments

are required As turbine performance is directly related to the flow conditions of the water stream entering the meter,

upstream fittings and piping changes can adversely affect flow registration For valid registration and proper performance,

consider the following installation considerations:

◊ When installing the meter with a Badger Meter Plate Strainer, a minimum of 5 pipe diameters of straight, unobstructed

pipe is required upstream of the meter (A minimum of 10 pipe diameters of straight unobstructed pipe is required

upstream of a meter installed without a plate strainer The deletion of a strainer, however, is not recommended ) This

allows for dampening of velocity profile distortions caused by items such as elbows, pumps and dirt traps upstream

of the meter Where spiral flows are created by three dimensional elbows or rotary pumps, use additional distance

to dampen the effect If a basket or Y-type strainer is used, place it 5 to 10 pipe diameters upstream of the meter to

dampen velocity profile distortions created by this design

Installation

June 2016

RCS-UM-00076-EN-04

Page 6