SERVICING PARTS AND ASSEMBLIES

When the performance of a compound meter indicates a need for servicing, refer to the following instructions pertaining to

removal, inspection and installation of service parts and assemblies Also see the

Recordall Compound Series Meter Parts List

for

part numbers of replaceable components and correct ordering information If satisfactory repair cannot be made, contact

Badger Meter

Removing the High Flow Turbo Meter Head Assembly

A typical installation would be equipped with drain and piping valves To inspect or replace components of the High Flow

Turbo Head Assembly, close the upstream and downstream valves However, if the installation does not have a drain valve,

proceed as follows to relieve pressure See

UPSTREAM AND DOWNSTREAM VALVES MUST BE CLOSED BEFORE ATTEMPTING TO REMOVE METER HEAD FROM

HOUSING. FAILURE TO DO SO CAN LEAD TO THE HEAD BEING "EJECTED" FROM HOUSING, CAUSING PERSONAL INJURY

AND/OR PROPERTY DAMAGE!

1 Loosen each of the High Flow Turbo Head Assembly bolts about 1-1/2 turns Do not completely remove the bolts

2 If the O-ring between the High Flow Turbo Head Assembly and the housing is secure and not leaking, pry the

Measuring Element Assembly loose by inserting a screwdriver blade where the head and housing join together

BE SURE THAT ANY WATER COMING OUT OF THE METER HEAD DOES NOT SPRAY ONTO ELECTRICAL EQUIPMENT AND

CREATE A SHOCK HAZARD.

3 Allow the meter to drain and relieve internal pressure

4 When pressure is relieved, remove the head bolts Lift the Turbo measuring element assembly from the housing

5 Follow the instructions for

“Servicing the Chamber and Disc” on page 19

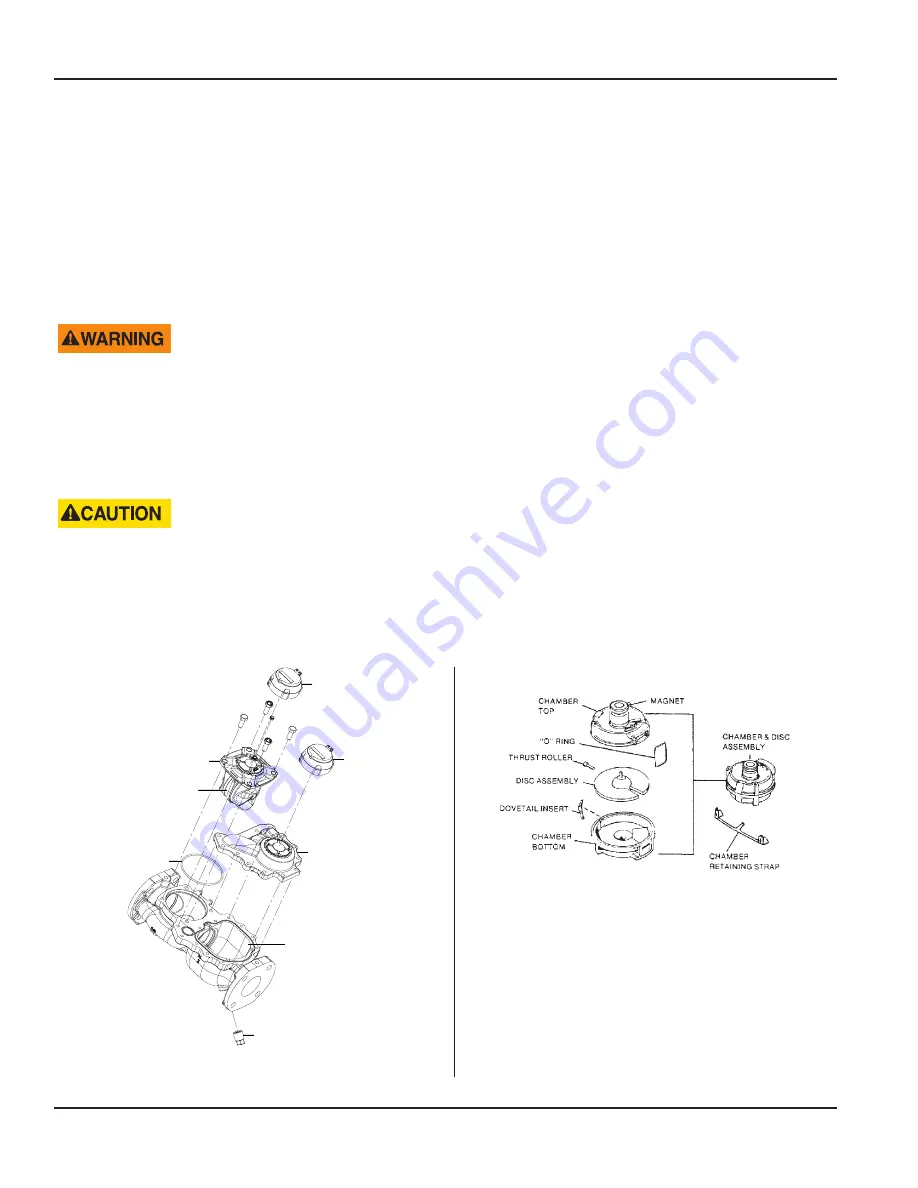

Drain Plug

Cover

Assembly

Low Flow

Register

High Flow

Register

High Flow Turbo

Meter Head

Assembly

Cage Seal

O-Ring

Housing

Figure 8: Removing the high flow turbo meter head assembly

Figure 9: Chamber and disc assembly

Servicing Parts and Assemblies

June 2016

RCS-UM-00076-EN-04

Page 12