3 If a leak exists at this point in the disassembly of the meter, remove the calibration shaft O-ring Before reinserting the

O-ring, apply a light coat of silicon grease to it

4 Clean all parts

To gain access to the calibration ring, the straightening vane/nose cone must be removed See

“Removing the Magnet Carrier/Top Gear Set” on page 14

for instructions

To remove the calibration ring from the nose cone assembly:

1 Align the ring slots with the bayonets of the nose cone assembly (located on inner ring of calibration ring)

2 Carefully lift the calibration ring from the nose cone assembly

To reinstall the calibration mechanism, follow this procedure in reverse

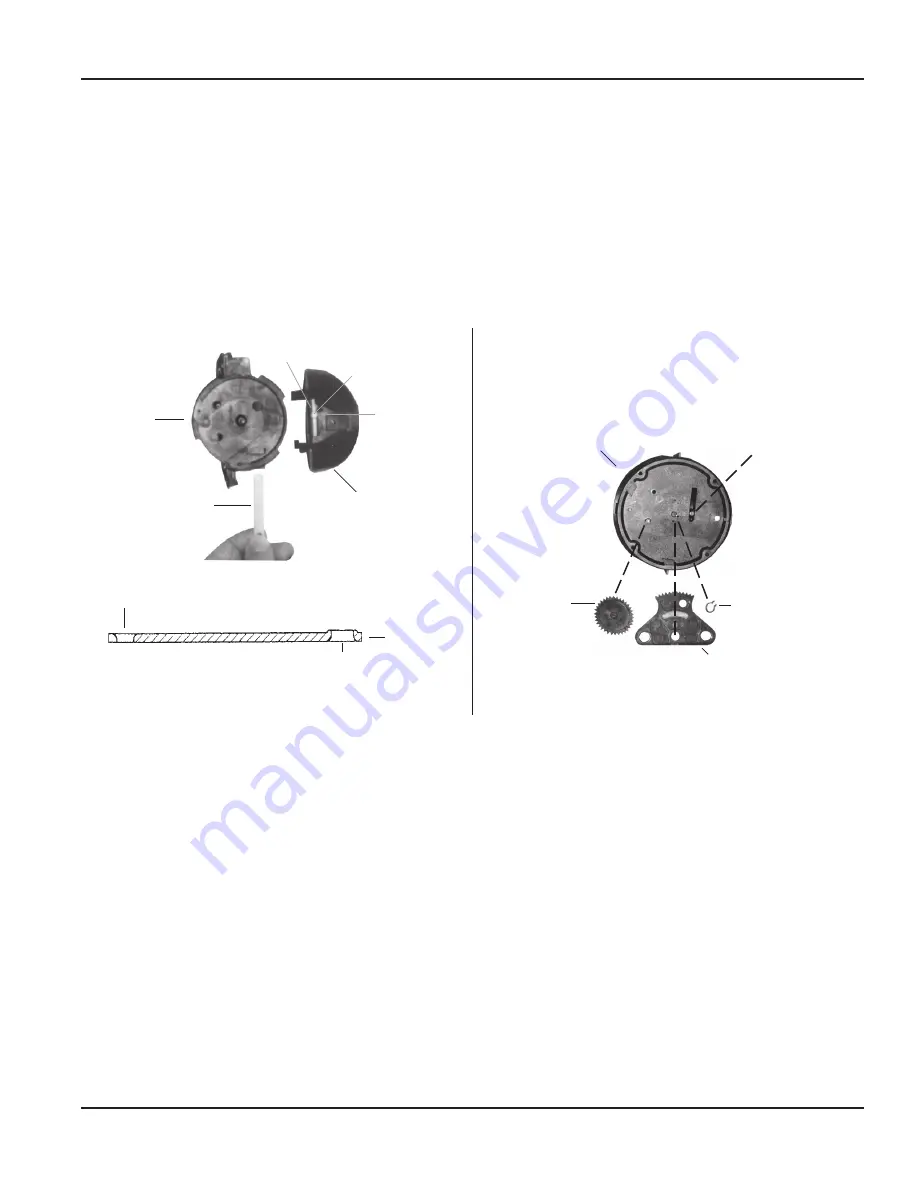

CALIBRATION

LINKAGE

ARROW TIP

CAGE

INSERT

NOSE

CONE

TOP SIDE

SMALL HOLE WITH

CHAMFER UP

LARGE HOLE WITH

CHAMFER DOWN

INTO CAGE

THIS END

CALIBRATION RING

PIN

2", 3" and 4"

RETAINING RING

TRANSMISSION

GEAR

CALIBRATION DRIVE

PLATE

CAGE INSERT

(TOP VIEW)

PIN OF

CALIBRATION

RING

6"

Figure 11: Calibration ring/linkage assemblies

Reassembling the Calibration Mechanism

1 Align the pin on the perimeter of the calibration ring with the arrow tip located on the nose cone assembly (see

)

2 For 2", 3" and 4" sizes, install the calibration linkage into the cage with the larger hole to engage the calibration ring

tab, with the side of chamfered edge of the hole towards the nose cone assembly (see

3 With the calibration linkage fully inserted to the cage stop, install the nose cone onto the cage and rotate it counter-

clockwise to engage the pin of the ring to the calibration linkage The hole of the calibration linkage has to be aligned

onto the calibration shaft, engaging it fully so that the calibration ring cannot vibrate during operation

4 Tighten the calibration shaft lock screw to securely hold the calibration ring in position

After servicing or replacing the calibration mechanism, check the accuracy and calibration according to the instructions in the

Recordall Turbo Series Meter User Manual

Servicing Parts and Assemblies

June 2016

RCS-UM-00076-EN-04

Page 15