68OM-06/03

22

MAINTENANCE

To assure safety, disengage the

engine clutch lever, remove the

ignition key, and disconnect the engine spark plug

wire prior to making any of the following adjustments.

Handle reel assemblies carefully

with protective gloves. Reels are

very sharp. Reels rotate freely and rotating one reel

can cause other reels to rotate. Special care should be

taken in the area where the reel contacts the bed knife.

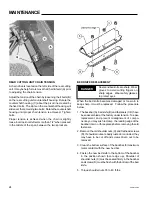

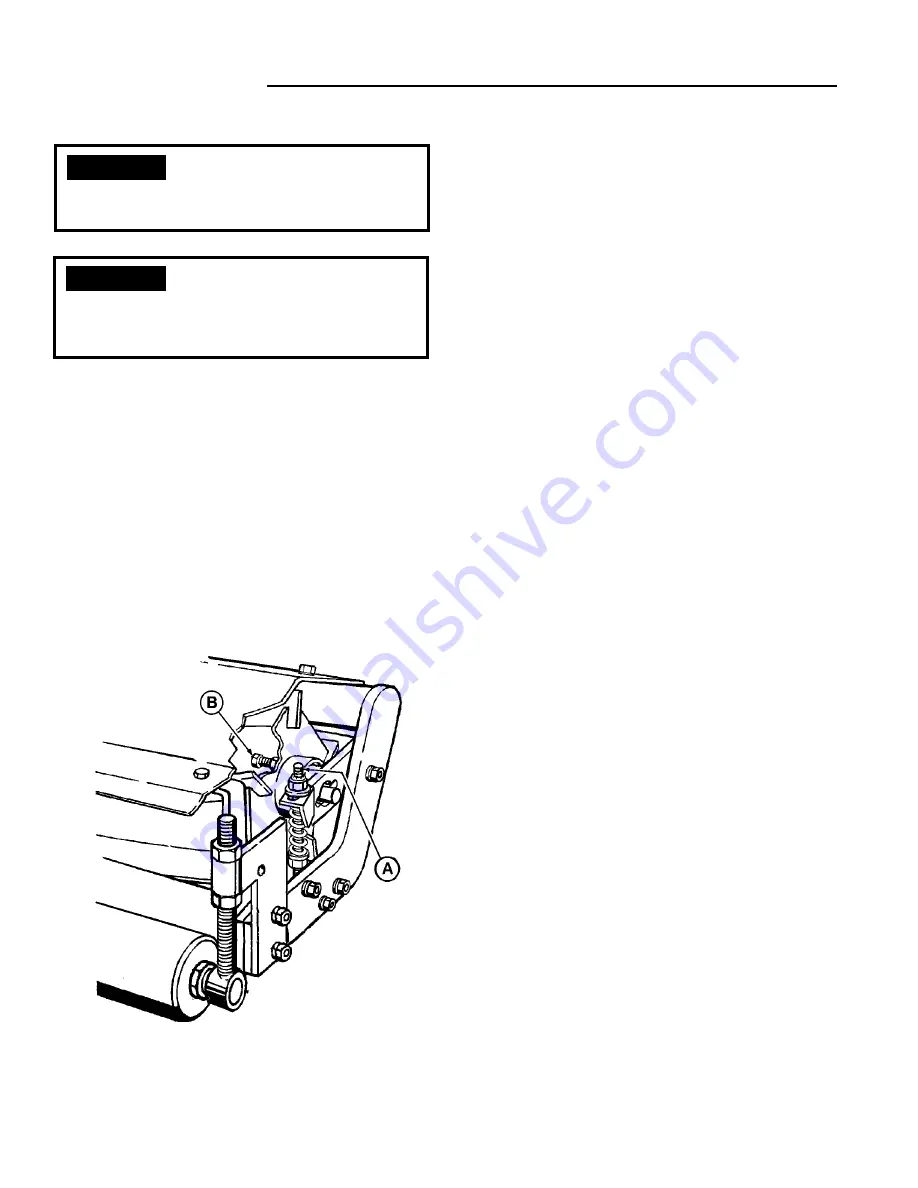

REEL TO BED KNIFE ADJUSTMENT

The reel is adjusted to a fixed position bed knife. This

construction allows a more rugged and durable frame and

retains the proper adjustment longer. The Reel Adjuster

Bolt (A) regulates reel distance from the bed knife.

To reduce the distance, turn the upper hex adjuster nut on

each side of the reel down. Proceed slowly and do not

over-adjust -- use about 1/8 of a turn on each side at first.

REEL ADJUSTMENTS

Do not adjust one side more than the other unless the reel

is obviously out of alignment. Do not get the reel so tight

that it is hard to turn by hand. A too tight reel will wear

faster.

Ideally, the reel should “wipe” or lightly touch the bed

knife. It is not necessary to adjust or change the position

of the lower adjustment nut.

Proper cutting action may be tested by holding paper

strips between the reel and the bed knife. Turn the reel by

hand and check to see if the assembly cuts the paper all

the way across the width of the bed knife. Make sure that

the adjusting and the locking nuts on both side are

tightened securely.

REEL END PLAY ADJUSTMENT

Test for end play periodically by trying to move the reel

from side to side in the frame. If there is ANY movement,

adjust the bearings by loosening the lock nut on the

adjustment bolt (B) which is located on the inside right end

of the reels, and turning the adjustment bolt IN one half

turn or less. Do not overtighten. An overtightened bearing

will cause excessive bearing wear. Test again for end

play and if reel is rotating freely and end play is not

noticeable, tighten the lock nut.

HEIGHT OF CUT ADJUSTMENT

Refer to "Height of Cut Adjustment" in the Operation

section of this manual.

BRAKE ADJUSTMENT

The foot brake is properly adjusted if it slows the machine

when depressed and can be locked when the pedal is

depressed fully.

Adjust brake tension by removing cotter pin and brake

pedal pin and turning brake clevis located under pedal on

brake rod. When adjustment is complete, attach clevis to

pedal with pin and cotter pin.

NOTE: Guards removed or cut away to show detail

DANGER

DANGER

Summary of Contents for 68 DL TRIPLEX

Page 26: ...68OM 06 03 26 MAINTENANCE RECORD e t a D k s a T e c n a n e t n i a M n o s r e P ...

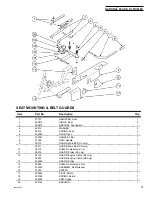

Page 28: ...68OM 06 03 28 FRAME RUNNING GEAR PARTS LIST ...

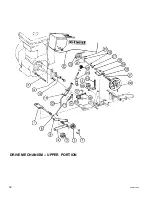

Page 32: ...68OM 06 03 32 DRIVE MECHANISM UPPER PORTION ...

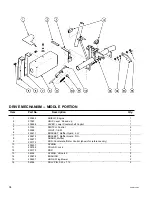

Page 36: ...68OM 06 03 36 DRIVE MECHANISM MODEL 68 DL ...