GB - 23

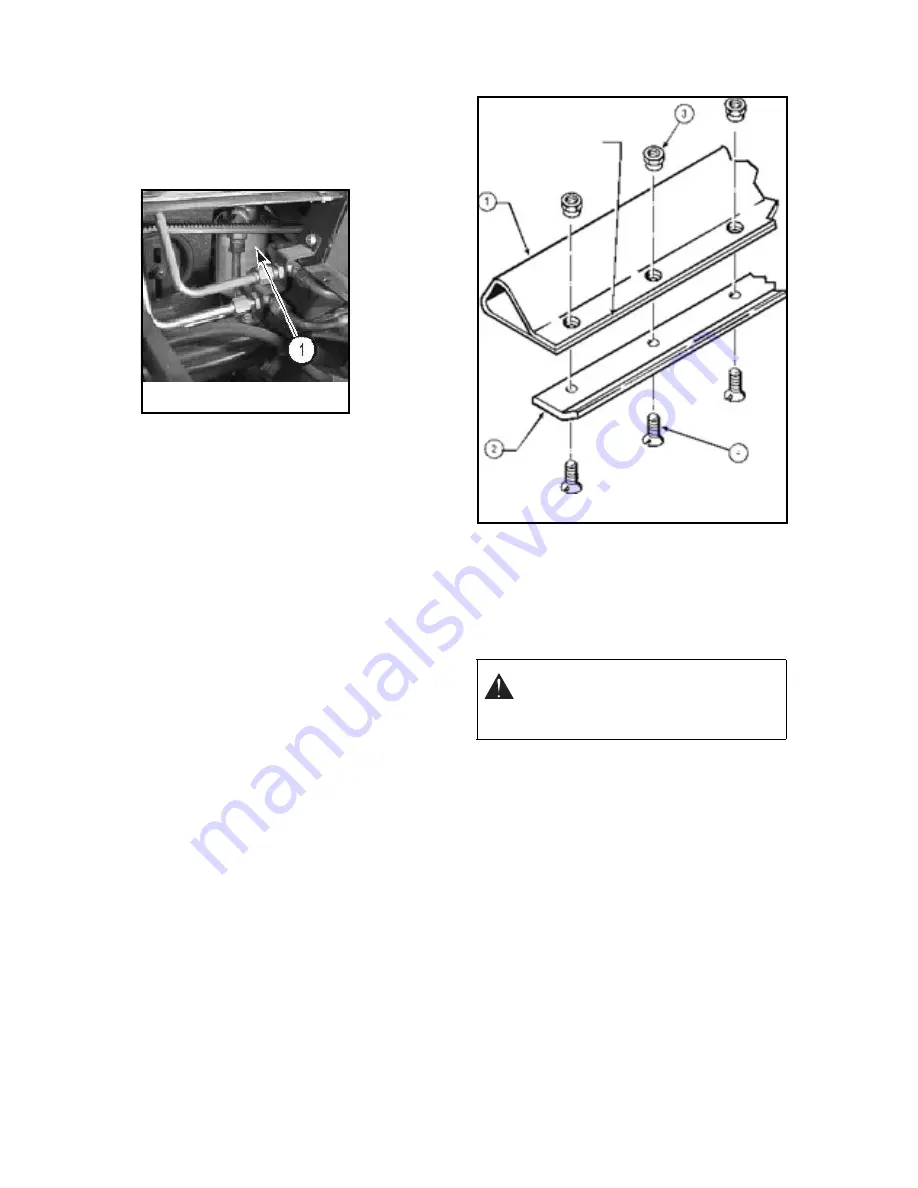

HYDRAULIC OIL FILTER

To prevent damage to the hydraulic system,

the hydraulic oil filter (1, Figure 21), located

under right fender, should be changed after

the first 25 hours of operation and every 250

hours thereafter.

1. Remove the old filter.

2. Install new filter, filling filter with oil

before re-installing. Apply oil to the

o-ring of the filter prior to installation.

Hand-tighten only.

3. Run engine at idle speed with

hydrostatic pump in neutral for five

minutes.

4. Check hydraulic oil level, and add oil if

necessary. Frequently check oil level in

the hydraulic tank. Should the pump run

short of oil, immediate and permanent

damage will result.

BEDKNIFE REPLACEMENT

When the bedknife becomes damaged or too

worn to keep sharp, it must be replaced.

Follow the procedure below.

1. The backbar (1, Figure 22), bedknife (2,

Figure 22), and fasteners have been

assembled at the factory under tension.

To ease replacement and prevent

misalignment of components, you may

wish to clamp the leading edge of the

backbar two or three places before

removing the old fasteners.

2. Remove shoulder nuts (3, Figure 22)

and flathead screws (4, Figure 22). If

shoulder nuts are badly rusted or

corroded, they may have to be cut off

and the screws driven out.

3. Clean the bottom surface of the backbar

for maximum metal contact with the new

bed bar.

4. Fasten the new bed knife to the bottom

of the backbar in the position shown

(bent edge up). Shoulder of shoulder

nuts must be seated firmly in the

backbar and screws must be flush with

the bottom of the bed knife.

5. Torque shoulder nuts 35 to 40 lbf/ft

(47.4 to 54.2 N•m).

LUBRICATION

Figure 23 shows the top view of the 8400 with

guards removed. Lubricate your tractor at the

recommended locations and intervals using

proper lubricants so that maximum service

and long life of the machine may be obtained.

Figure 21

CAUTION: Before doing any work

on your machine, stop the engine,

remove the ignition key, and set

parking brake.

Figure 22

Clamp this edge