OPERATING PROCEDURES

100 Avon Street, P.O. Box 1547

Charlottesville, VA 22902

Tel: 434-295-9126 Tech Support: 800-247-9796 Fax: 888-239-0778

Revision: 11/98 Page -

13

-

NATIONAL

INCORPORATED

It is suggested that the operator now run additional test lenses, changing the bevel

placement and size. The operator can also experiment with the three control features (

Finish

Only

,

Rimless

, and

Pause

), to gain a familiarity with the edger’s operating sequence and

controls.

BEVEL PLACEMENT SYSTEMS - TWO ALTERNATIVES:

The edger is supplied with two methods of controlling the placement of the bevel (or

groove) on the periphery of the lens.

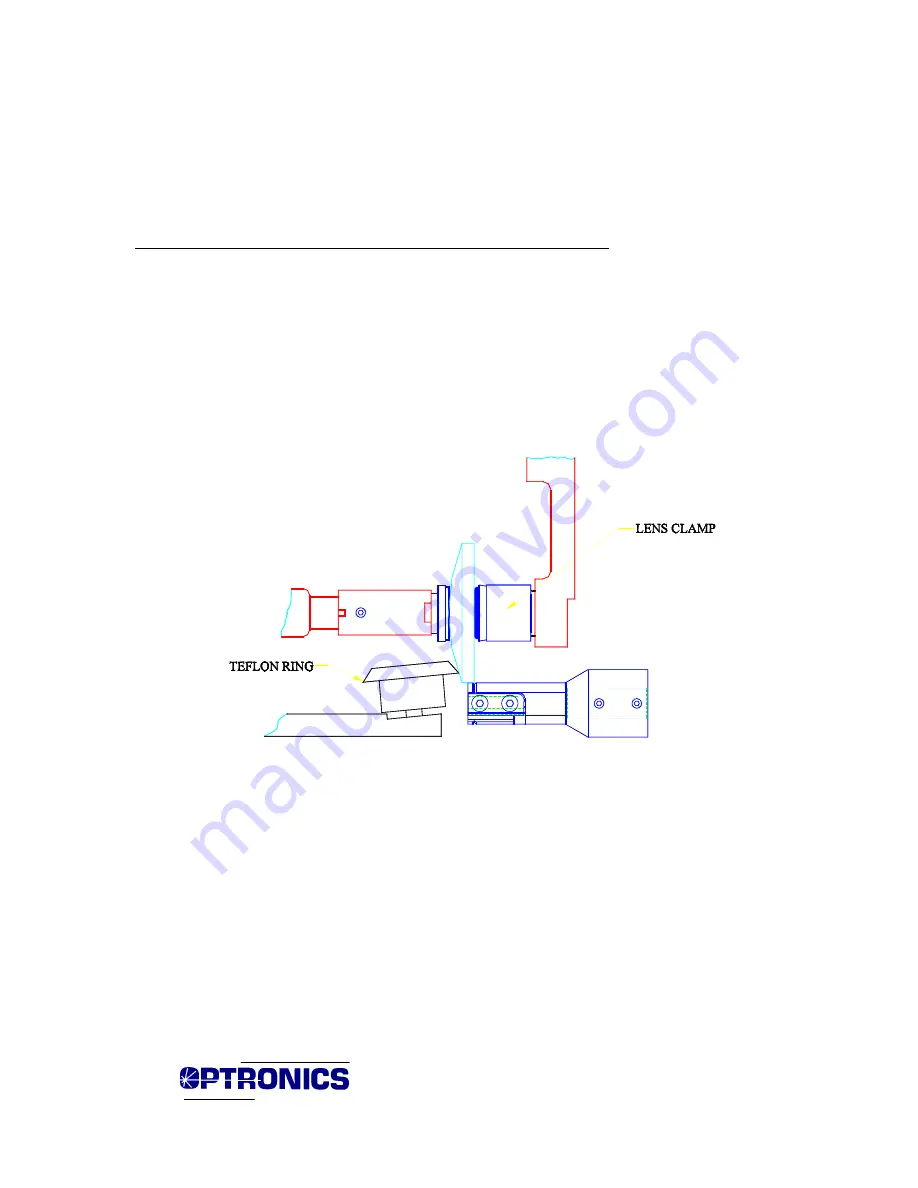

Front Curve Tracking Bevel System In Place

The bevel guide wheel tracking system uses a Teflon wheel, which tracks the front

curve of the lens (

Fig. 4

). The position of the wheel is controlled by the knob on the right

side of the edger.

Figure 4 – Front Curve Tracking System in Place

It is important that the edge of the Teflon guide wheel be concentric within a few

thousandths of an inch, as the bevel, groove and facet placements on the lens are extremely

responsive to the position of the wheel. It is advisable to occasionally run your finger around

the wheel edge to dislodge any particles and check for wear. See the Maintenance section for

instructions on changing the wheel.

Note:

The position of the bevel guide wheel is factory-set at the beveling position. When

running faceted lenses, the wheel must be raised away from the cutter to allow clearance for

the top of the ramps. (Refer to the Faceting procedures.)