Page 8

ASSEMBLY (continued)

FOR SHIPPING, WHEEL ADJUSTMENT PINS ARE NOT INSERTED CORRECTLY THROUGH

HANDLE FRAME.

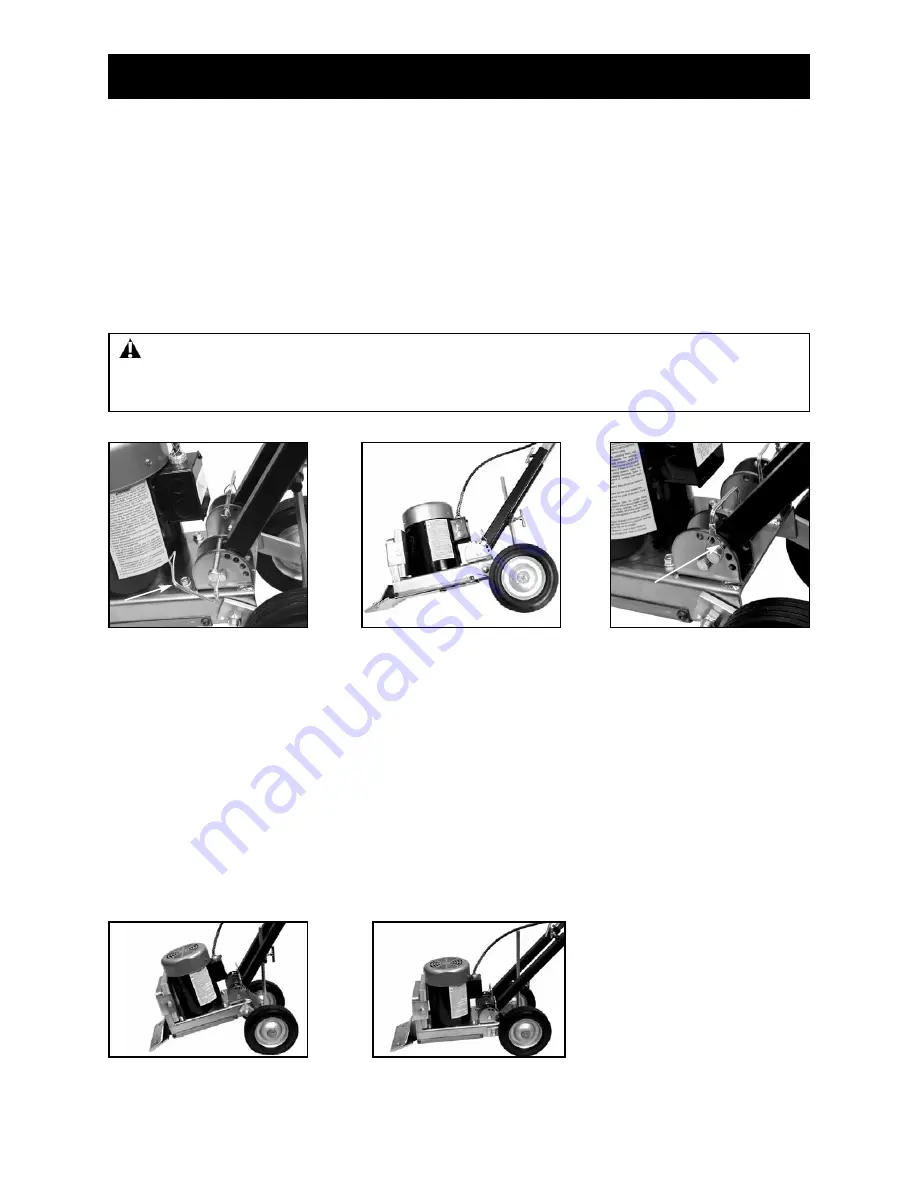

1. Remove handle adjustment pins (See Figure A). It may be necessary to maneuver handle so it is not

touching the handle adjustment pins. OR, lay machine onto side (See Figure B).

2. Adjust handle to proper angle (center hole is the most common).

3. Insert handle adjustment pins into desired hole (See Figure C) and secure.

WARNING:

Do not operate machine around excessive moisture areas, such as abatement work

and flooded pool areas without GFI wall plug (stock #530 Circuit Guard). Failure to do so could cause

damage in machine or injury to operator.

Figure A

Figure B

Figure C

GENERAL OPERATION

Remove handle

adjustment pins

Insert pin into

desired hole

WHEEL ADJUSTMENT

Adjusting wheel angle will change the blade angle to the floor. A steep wheel angle is recommended on

hard tear-outs such as tile over concrete (See Figure D). A low wheel angle is recommended on vinyl

tear-outs and plywood floors (See Figure E).

1. Loosen T-Bolt on adjustment T-bar.

2. Adjust wheels (by handle) to preferred angle.

3. Securely tighten T-bolt on adjustment T-bar.

NOTE:

Adjustment by trial at the beginning of a job will give optimum performance.

Figure D

Figure E

Steep Angle

Low Angle

Lay unit on side