20

NON-DIRECT VENT

INSTALLATION

GUIDELINES

IMPORTANT:

Failure to correctly follow

all venting guidelines may result in

erratic furnace operation, freeze-up of

combustion air or exhaust air piping or

sooting of the furnace.

All exhaust piping must be installed in

compliance with Part 7, “Venting of

Equipment,” of the latest edition of the

National Fuel Gas Code NPFA54/ ANSI

Z223.1-, local codes or ordinances and

these instructions.

1. Vertical piping is preferred.

2. All horizontal piping must slope

upward a minimum of

1

/

4

inch per

foot of run so that condensate drains

toward the furnace.

3. All horizontal runs must be

supported at least every 4 feet. No

sags or dips are permitted.

4.

IMPORTANT:

Do not common vent

with any other appliance. Do not

install in the same chase or chimney

with a metal or high temperature

plastic pipe from another gas or fuel-

burning appliance unless the

required minimum clearances to

combustibles are maintained

between the pvc pipe and other

pipes.

5. All vent runs through unconditioned

spaces where below-freezing

temperatures are expected should

be insulated with 1-in. thick,

medium-density, foil-faced

fiberglass. An equivalent “arm-a-

flex” or “rub-a-tex” insulation may

also be used as long as there is no

heat tape applied to the vent pipe.

For horizontal runs where water may

collect, wrap the vent pipe with self-

regulating 3 or 5 watt heat tape. The

heat tape must be U.L. listed and

installed per the manufacturer’s

instructions.

6. The minimum vent pipe length is

5 feet.

7. Extend the exhaust pipe a minimum

of 18” from the cabinet before turning

vent.

8. Vent cannot be ran underground.

FIGURE 14

TEE TERMINAL – FOR STANDARD

HORIZONTAL NON-DIRECT

INSTALLATION

VENT

12"

12" MIN. ABOVE

GRADE OR

SNOW LEVEL

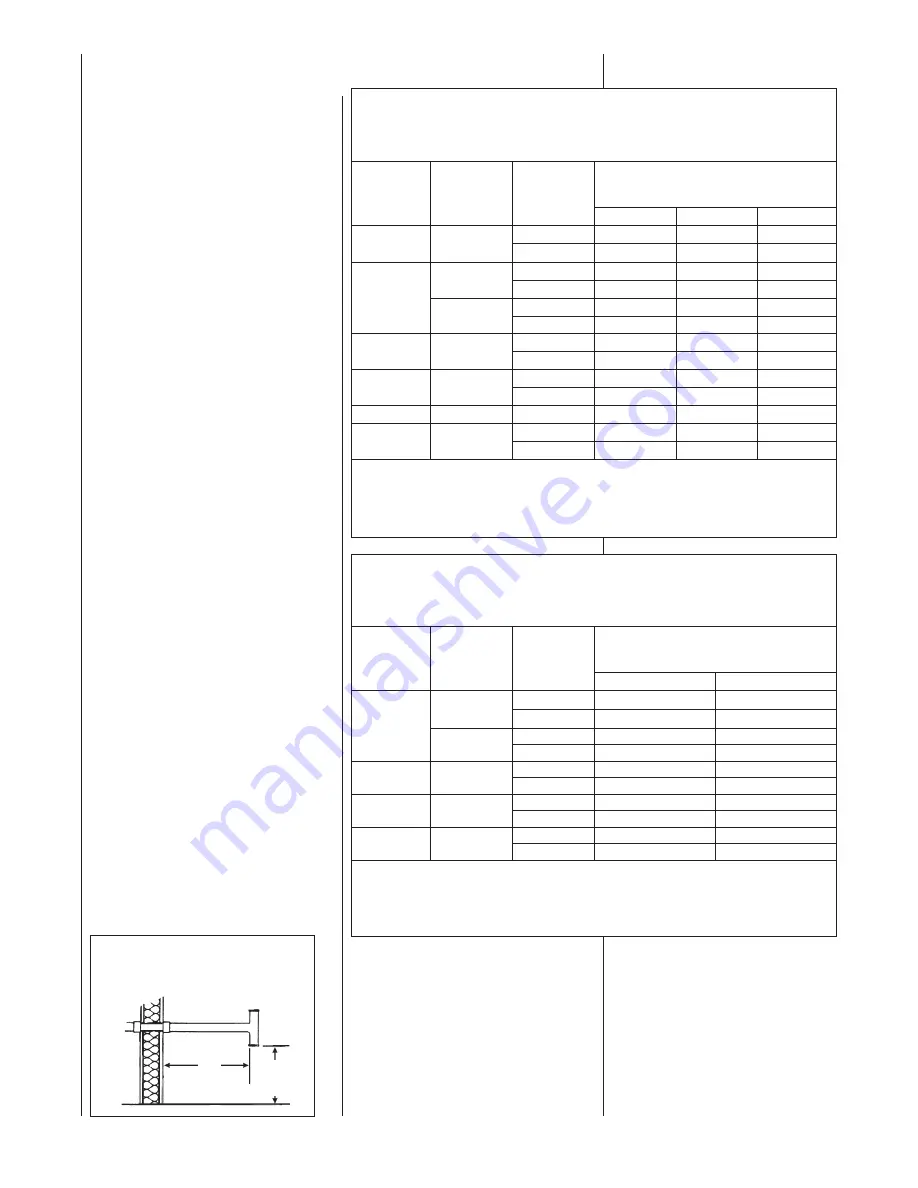

NUMBERS OF ELBOWS

45° OR 90°

Medium / Long Radius ONLY

1-2

3-4

5-6

2”

Standard

60

55

50

45,000

Alternate

55

50

45

2”

Standard

30

25

20

Alternate

25

20

15

60,000

3”

Standard

120

120

115

Alternate

120

120

110

3”

Standard

45

40

NR

75,000

Alternate

NR

NR

NR

3”

Standard

90

85

75

90,000

Alternate

60

50

45

105,000

3”

Standard

45

40

NR

120,000

3”

Standard

70

65

55

Alternate

40

30

25

NOTES:

1. *N.R. - NOT RECOMMENDED.

2. MAXIMUM OF 4 ELBOWS MAY BE USED. DO NOT COUNT ELBOWS REQUIRED FOR

ALTERNATE TERMINATION. USE ONLY MEDIUM OR LONG SWEEP ELBOWS.

3. A 45 OR 22.5 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. NO SCREENS MAY BE USED TO COVER EXHAUST.

*A = 17-1/2” CABINET WIDTH

B = 21) CABINET WIDTH

FURNACE

INPUT

VENT PIPE INSTALLATION

PIPE

SIZE

TERMINATION

TABLE 1

UPFLOW UNITS

FOR NON-DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM INDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE PIPE

ELEVATED SINGLE PIPE

ALTERNATE TEE

TERMINATION

See Figure 15. The tee termination may

be elevated up to 24 inches above the

wall penetration if required for anticipated

snow levels. Use 2 long-sweep, 2-in.

PVC elbows and 2-in. PVC pipe,

attaching the tee so it is 12 inches from

the wall.

NUMBERS OF ELBOWS

45° OR 90°

Medium / Long Radius ONLY

1-2

3-4

2”

Standard

50

40

Alternate

40

30

60,000

3”

Standard

50

40

Alternate

50

40

3”

Standard

50

40

75,000

Alternate

50

40

90,000

3”

Standard

50

40

Alternate

50

40

105,000

3”

Standard

50

40

Alternate

50

40

NOTES:

1. *N.A. - NOT APPLICABLE.

2. MAXIMUM OF 4 - 90 DEGREE ELBOWS MAY BE USED. DO NOT COUNT ELBOWS REQUIRED FOR

ALTERNATE TERMINATION. USE ONLY MEDIUM OR LONG SWEEP ELBOWS.

3. A 45 OR 22.5 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. NO SCREENS MAY BE USED TO COVER EXHAUST.

*A = 17-1/2” CABINET WIDTH

B = 21” CABINET WIDTH

FURNACE

INPUT

PIPE

SIZE

TERMINATION

TABLE 2

DOWNFLOW/HORIZONTAL UNITS

FOR NON-DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM INDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE PIPE