Electronic pellet burner controller – NPBC-V3C-1/ NPBC-V4C-1

Common Factory Settings for all types of fuel:

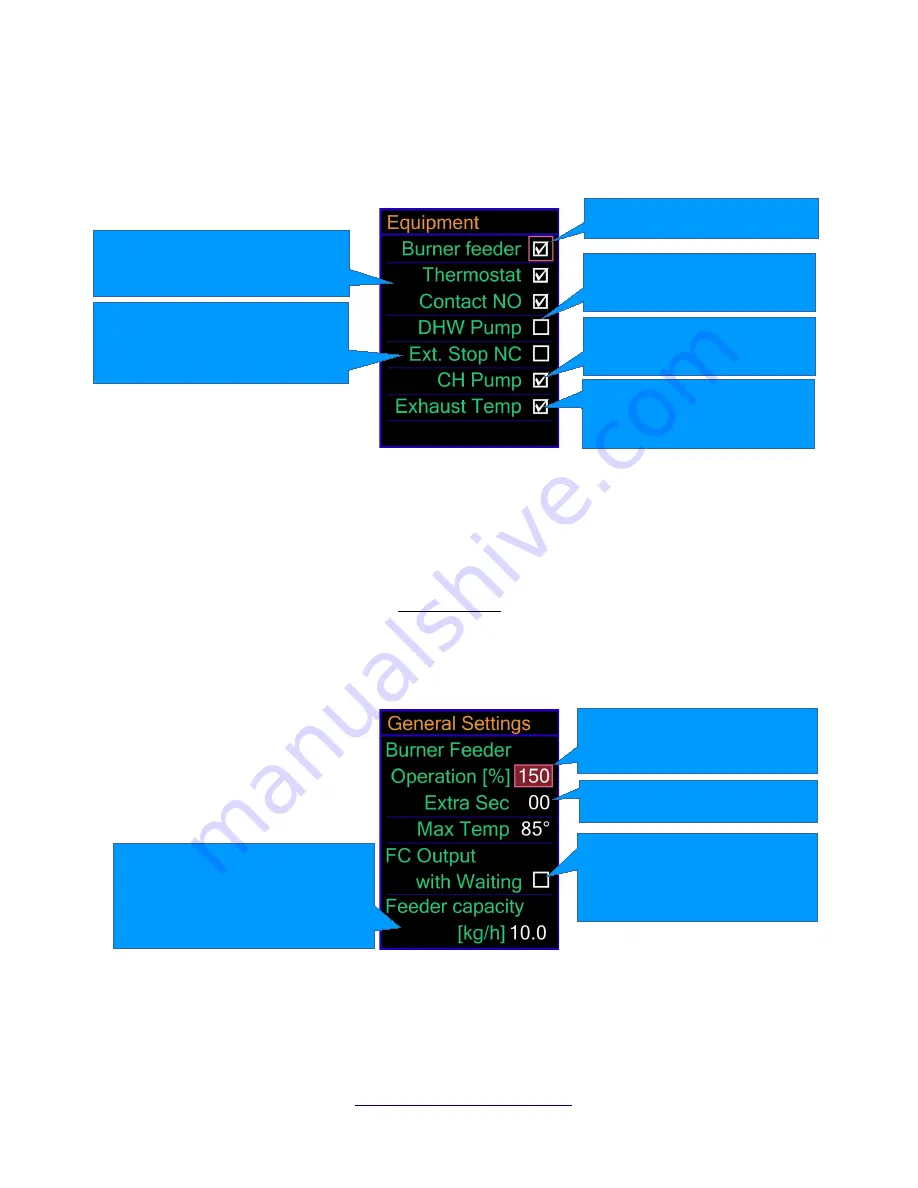

Equipment

– Enable/disable the additional mechanisms and sensors of the burner's configuration and

set the polarity of the room thermostat's and the OD input's contacts:

General Settings

– Set the internal auger motor's active time (Burner Feeder), the maximum allowed

set temperature for the boiler, the main auger's capacity and pending time for FC output, if necessary.

The internal auger motor always starts at the same time with the main auger and works for as long as it

is set in this menu. Its active time in seconds is:

T

ia

=

T

fa

∗

Operation

100

+

Extra Sec

where: T

ia

is the internal auger motor's active time;

T

fa

is the fuel auger's active time (main auger).

Instead of powerful cleaning fan, the FC output can control a mechanical cleaning actuator. During the

cleaning procedures where the FC output is active, the actuator moves in one direction to push out the

ashes. After the procedure is over the controller cuts the power supply to the FC output and the

actuator needs time to get back to its initial position. Put a check sign on the parameter FC output and

User Manual / ver 3.8

http://www.naturela-bg.com/en/

page 27 of 36

Put a check sign if the burner

works with an internal auger motor

Put check signs if the CH installation

has a room thermostat and its

contact is normally opened (NO)

Put a check sign if the burner

works with a high temperature

sensor for the exhaust gases

Put a check sign if the burner

works with an external stop switch

connected to the OD input

with normally closed contact (NC)

Check this box if the controller

comands a pump for

the hot water installation

The internal auger motor

will work 1.5 times longer

than the main auger

Additional seconds for

the internal auger's active time

If checked, every procedure where

FC output was supplied will be

followed by the same amount of

time without any voltage to it

Set this parameter to assure the

accuracy of the statistical information

for pellet consumption.

Check the instructions how to

calibrate the auger motor on page 20.

Check this box if the controller

comands a pump for

the central heating installation