Electronic pellet burner controller – NPBC-V3C-2 / NPBC-V4C-2

12

High Flue gas temp

button

„

◄

“ The exhaust temperature is too high

13

Flue gasses alarm!

button

„

◄

“ The exhaust temperature is extremely high and the

burner has stopped

14

Menu settings

---

Date and time of the last access to the Factory

Settings menu

15

No Exec module

---

No connection with the Executive module

16

Power On

---

Date and time when the power supply to the

controller was turned on

17

Power Off

---

Date and time when the power supply to the

controller was turned off

18

Begin

---

Date and time when the controller's software or the

information in the Diagnostics screen has been reset

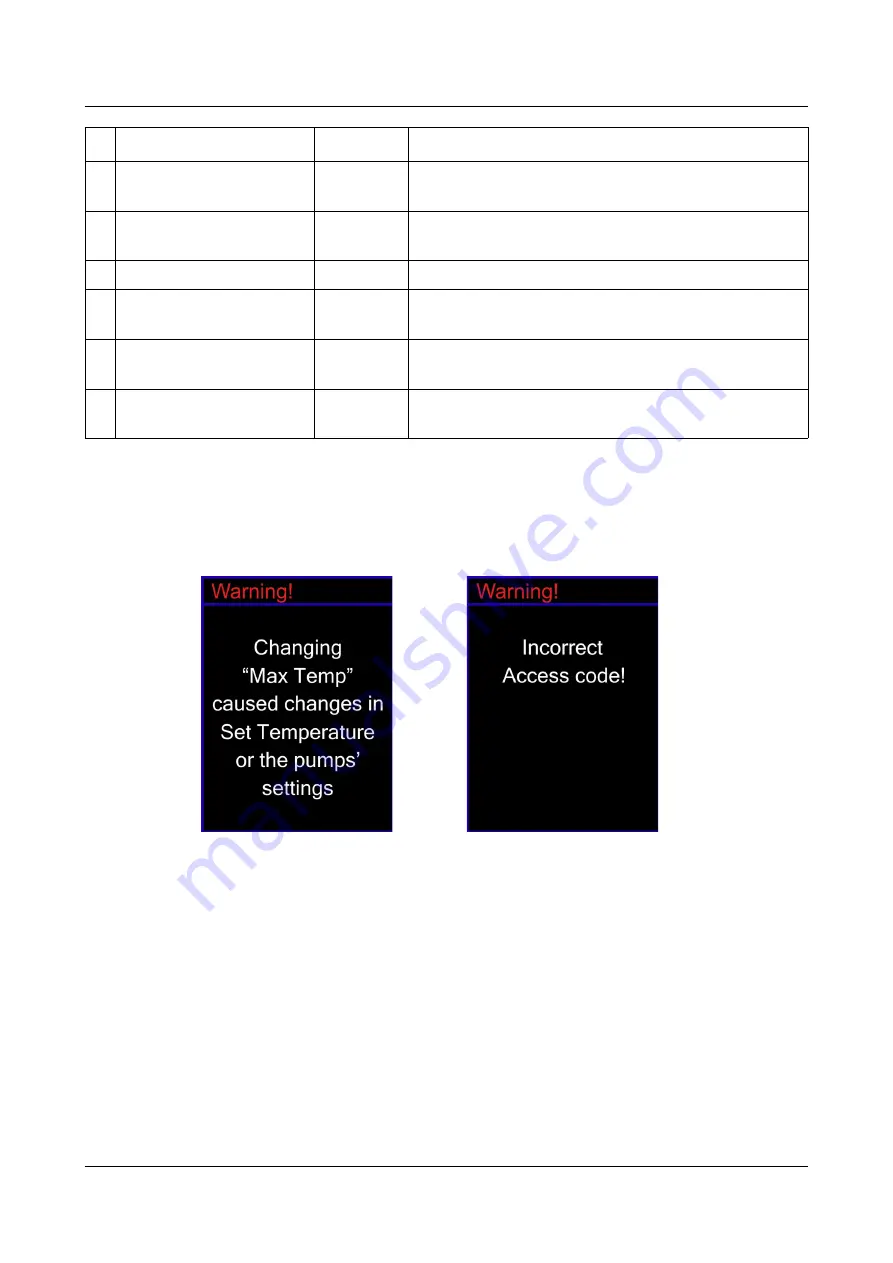

Automatic warning messages

In case of incorrect parameter input or if a change in the current menu caused changes in some of

the parameters from a different menu, the controller displays warning messages. For example:

Parameter settings

NPBC-V3C / NPBC-V4C has two main groups of parameters with an option for a different access

level to them:

User settings and Factory settings. Press the Menu button once to enter the User settings. They are

available for any user at any time. Press and hold the Menu button for more than 2 seconds to enter

the Factory settings. If the option for an access code has been activated, only users who know it can

access the Factory settings.

User Manual / ver3.8

http://www.naturela-bg.com/en/

стр. 17 от 37