Electronic pellet burner controller - NPBC-V3M

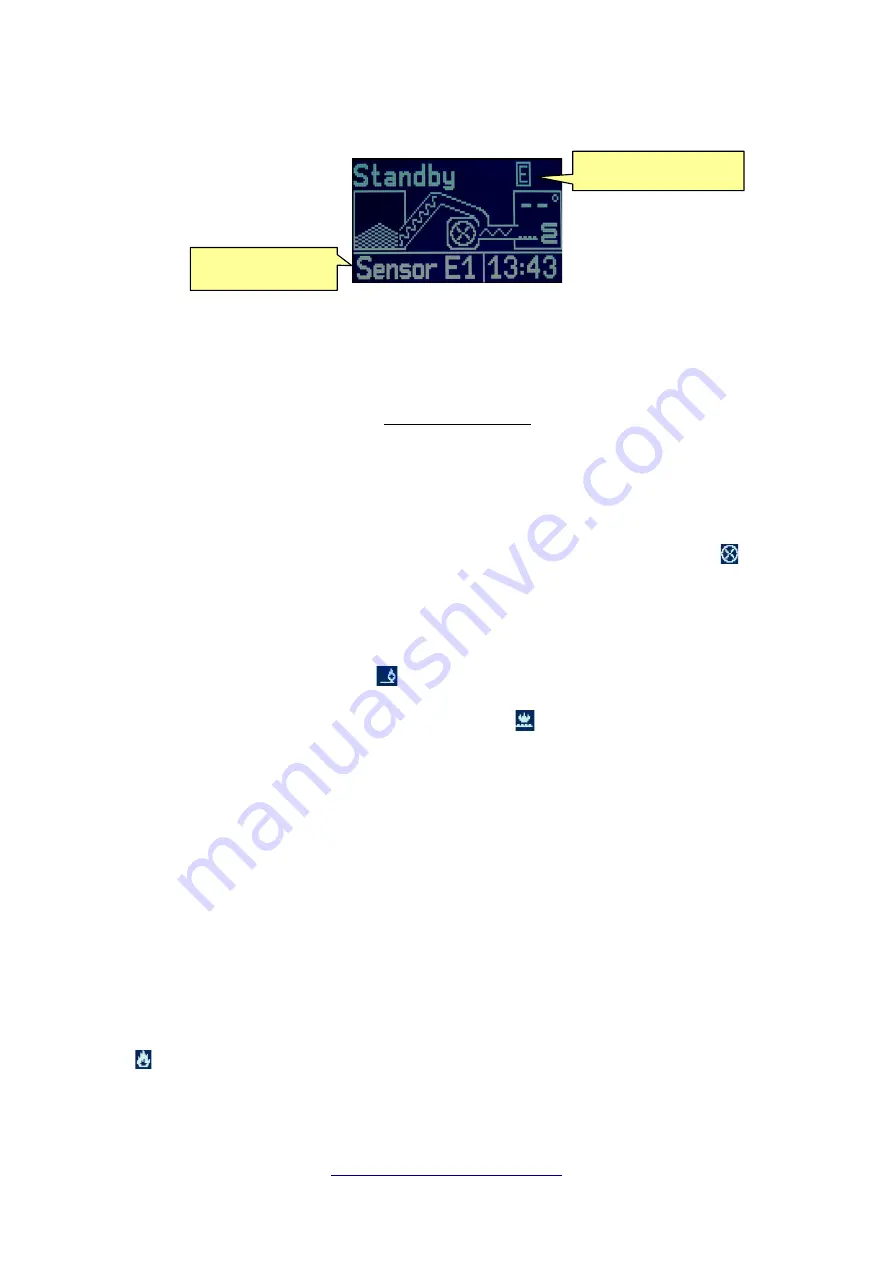

View of the screen when a problem is registered:

If there are any errors the current additional information switches with the error message and a sign

E

appears on the top right corner of the screen. The possible messages are listed above.

W

ORKING

METHOD

The burner can work either in continuous automatic mode (

Auto

)

or in mode with timers. When it is

in a timer mode, the burner works only during the intervals of the day set by the user. While working,

the burner goes through several stages: cleaning, igniting, burning, extinguishing, cleaning again and

initial state.

Every ignition begins with a cleaning cycle, which is indicated by the symbol for a fan in the upper

right corner of the screen (field

work phase

). The purpose is to clean all leftovers of the previous

burning. At first, for a certain time, set in the

Cleaning on Start

menu, only the primary fan works and

after that the additional cleaning fan turns on, if there is any and if it is activated from the Hardware

Setup menu. After that the burner goes to igniting phase.

The igniting is indicated by the symbol

in the upper right corner of the screen (field

work phase

).

A portion of pellets, which is going to be ignited by the electrical heater and the fan, is loaded. When

the flame sensor indicates the pellets are burning, a symbol appears in the

flame indicator

field and

the burner goes to burning phase. If the pellets do not ignite before the set time is up, a new portion of

pellets is loaded and a new attempt for ignition is made. After as many retries as set in the menu

General Setup

, if there still is no fire, the burner stops and a message

Ignition fail

appears.

The logic on igniting is as follows:

1. At first the heater turns on and works without air fan for as long as it is set in the menu

Cycle

Setup

, line

Heater

. The purpose is to heat up faster.

Should watch out for the heater not to get

overheated and damaged, if the time for turning on the cooling is too long!

2. At the same time, while turning on the heater, a dose of pellets is fed for so long as it is set in

the menu:

General Setup

, line

Feed

.

3. After the time for the heater, working without air fan, runs out, there are two more steps on

which the air fan turns on. The idea is that the air fan works less intensive at first, so that it

doesn't extinguish the fire, but only keeps the needed oxygen level. After the fire is steady, the

fan's speed can be increased for full igniting of all the pellets.

4. If the photo sensor detects enough light, which can be set from the menu

IR Level Setup,

line

, the ignition cycle breaks off and the burner goes to work mode. Two parameters are used for

recognizing the light level – light level, measured by the photo sensor and time the illumination

is over this level.

User Manual / version 2.6

http://www.naturela-bg.com/en/

page 11 of 27

Sign for a problem in

the controller

Description of the

problem/problems