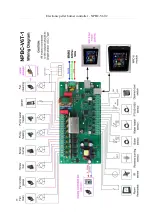

Electronic pellet burner controller - NPBC-V6T-2

Mechanisms and sensors controlled by

NPBC-V6T-1

•

Electric feed screw motor to transfer the fuel from the bunker to the burner (power up to

180 W)

•

Electric internal auger motor to forward the fuel into the burning chamber (power up to

180W)

•

Main blower with smooth speed control to regulate the air flow (power up to 180W)

•

Additional cleaning fan (power up to 900W)

•

Linear cleaning actuator with one or two control outputs (up to 180W).

The second output

is an option (AUX)!

•

Exhaust gases fan with smooth speed control (power up to 180W)

•

Heating element to fire the pellets (power up to 900W)

•

Hot water Beamer circulation pump (power up to 180W)

•

Central heating installation circulation pump (power up to 180W)

•

(Optional)

Analogue output (0..10V) for frequency inverter to power up a powerful air fan

•

Photo sensor to detect the burning fire

•

Temperature sensor or thermostat to control the back burning

•

Temperature sensor to control the temperature of the water in the boiler

•

Temperature sensor for the hot water heater

•

High temperature sensor pt100 for detecting the fire and control the temperature of the

exhaust gases.

•

A potential free contact of a room thermostat for better control of the burner and

circulation pump of the heating installation according to the room temperature.

•

Connector for additional control module with room thermostat function NRC-8-SV

•

USB interface for connection with a computer for software uprade

User Manual / ver. 1.2

http://www.naturela-bg.com/en/

page 5 of 41