https://www.naturewater.eu

Item 63922, 63923

Page 4

11 2023-1

•

The permissible ambient temperature of the system is 5–40

℃

. The ion exchange resin in the

housing can easily freeze and break. If in doubt, take suitable frost protection measures so that

the resin is not affected.

•

During operation of the water softener, shocks to the water must be avoided, e.g., by quickly

opening or closing the valve and switching off the water pump in emergencies.

•

Do not apply force to the machine and avoid direct sunlight and exposure to heat from other

sources.

Technical specifications

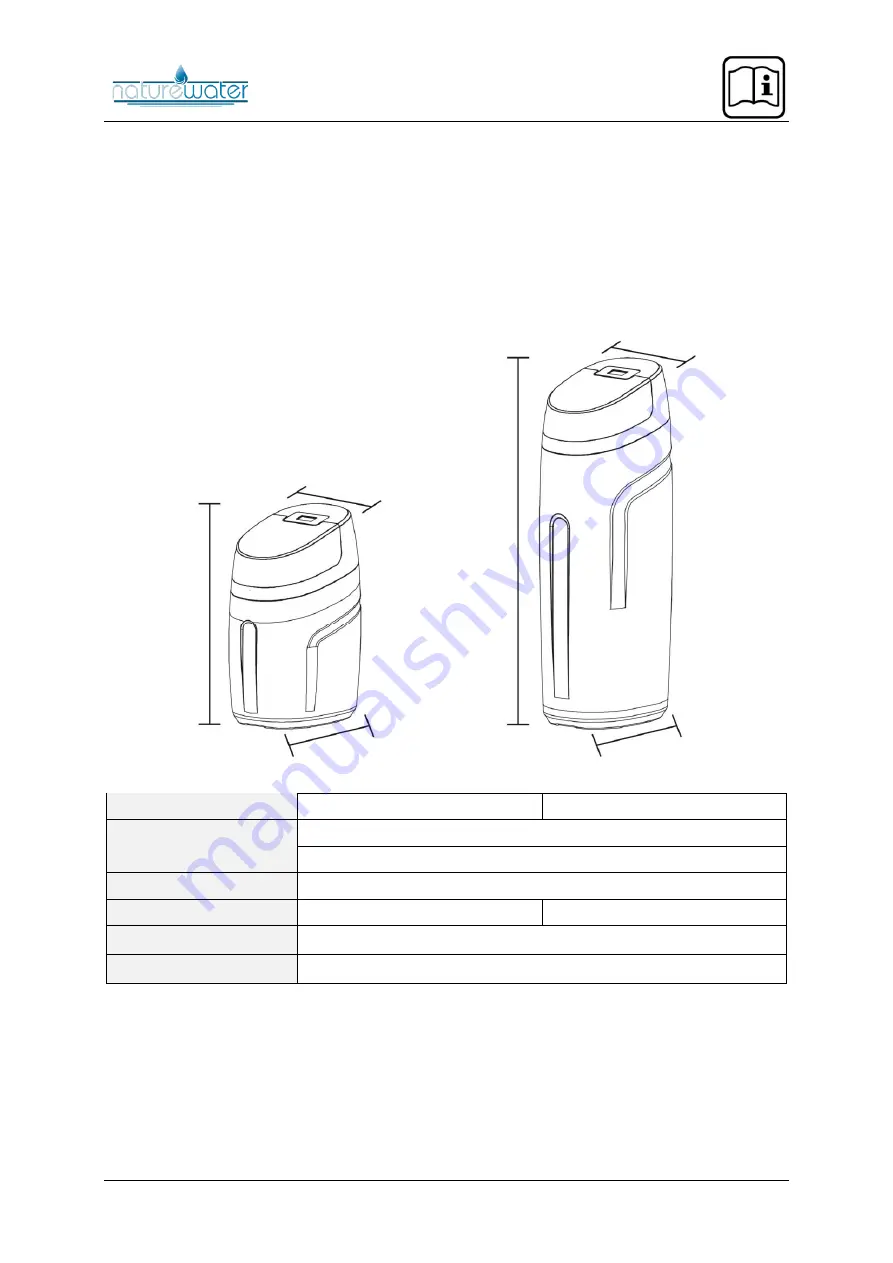

Model name

SOFT-V1

SOFT-V2

Power supply

230

V/50

Hz

Power consumption

(W)

18

Pressure

(bar)

1.5–4.5

Flow rate

(

ℓ

⁄

h

)

1500

3000

Max. temperature

(

℃

)

40

Min. temperature

(

℃

)

5

mm

mm

mm

mm

mm

mm