1

2.0 ReMoVInG UPRIGHTs

Tools needed:

• Phillips head screw driver

• 5/32 Allen wrench

• 3/4 inch wrench or socket

• 1/2 inch drive Ratchet

• 1/2 inch drive Torque wrench

step 1:

Remove for the four Button head screws at-

taching the console to the Upright weldment,

disconnect the cables and remove the console

from the machine.

step 2:

Remove the Rear Step as directed in Section 1:

Removing Rear Step.

step 3:

Disconnect the Base Cable (P/N - 17826) from

the Handrail Cable (P/N - 17824) located in the

lower left hand corner (see Figures 2-1 and 2-2).

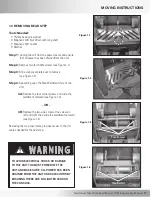

step 4:

Remove rear plastic cover by loosening six (6)

screws (see Figure 2-3 and Figure 2-4).

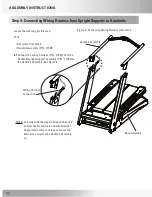

step 5:

Remove right and left lower plastic parts by

removing seven (7) screws located on the right

and left upright inside panels (see Figure 2-5 and

Figure 2-6).

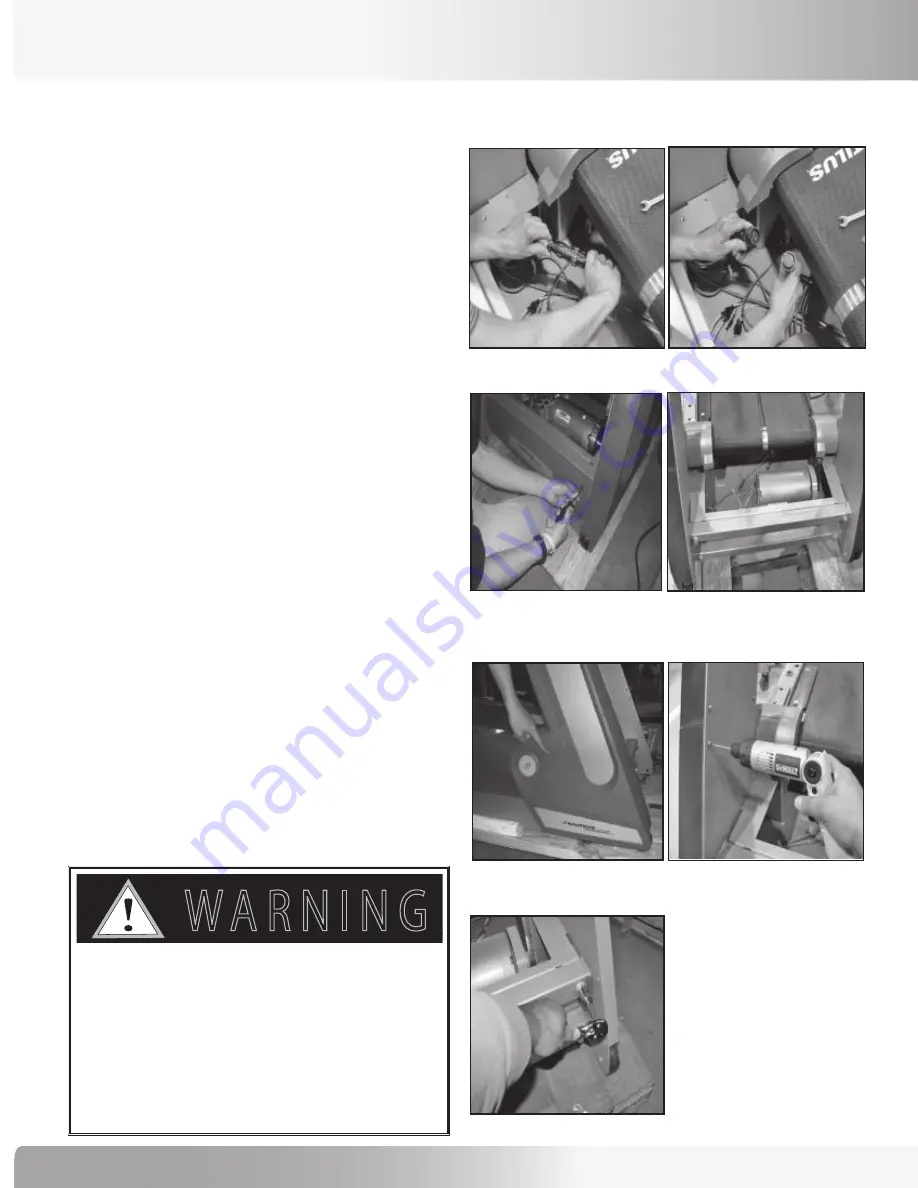

step 6:

Remove the four (4) upright bolts (see Figure 2-7)

step 7:

Wheel upright structure away to safe location

(wheels are integrated into upright portion of

unit).

noTe:

To replace the upright unit, reverse the

directions.

The four handrail screws are

to be torqued to a setting of 75 ft. lbs.

figure 2-1

figure 2-2

figure 2-3

figure 2-4:

Rear plastic cover off.

figure 2-5:

lower plastic parts.

figure 2-6

figure 2-7

detaching and moving the upright portion oF

this product requires two people! you must

have a minimum oF two people to properly

support the heavy upright structure so the

console does not Fall and cause damage to

the unit.

7 ! 2 . ) . '

! 4 4 % . 4 ) / .

$ ! . ' % 2

)--%$)!4%!#4)/.2%15)2%$

# ! 5 4 ) / .

MoVInG InsTRUcTIons