55

!

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet

and the machine and wait 5 minutes before cleaning, maintaining or repairing the machine. Place the power cord in a secure

location.

NOTICE:

It is necessary to remove the Shrouds for this procedure. Refer to the “Replace the Shrouds” procedure.

It is necessary to adjust the Drive Belt tension at the end of this procedure. Refer to the “Belt Tension Adjustment” procedure

Note:

Your machine may not match the image. For reference only.

1.

Carefully remove the Shrouds. Refer to the “Replace the Shrouds”

procedure.

2.

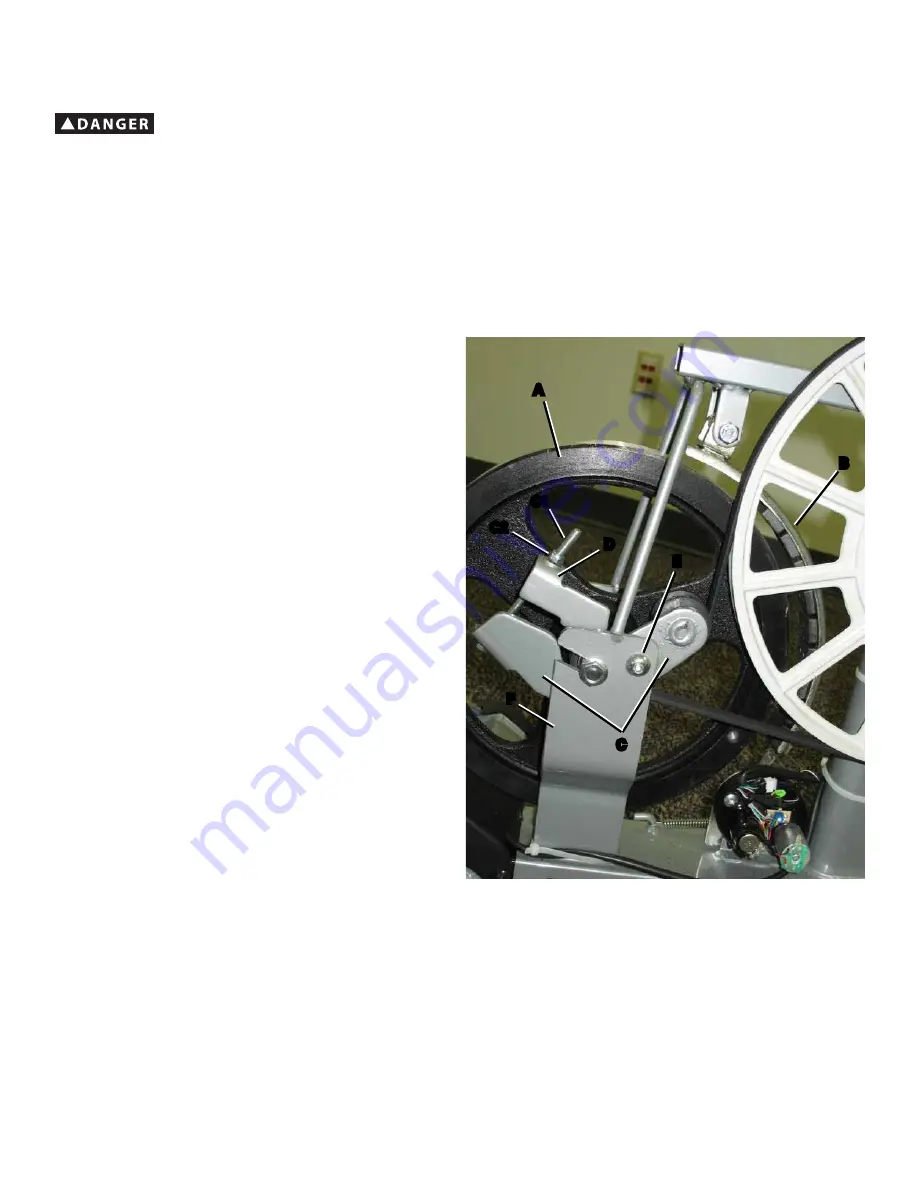

Insert 2.5” x 10” cardboard between the Flywheel (A) and the Brake

Magnet (B), and tape the cardboard to the Brake Magnet.

Note:

Be sure the cardboard covers all of the Brake Magnet.

3.

Observe the position of the Tensioner Assembly (C) on the Frame

upright (F) and mark the position on the Tensioner Assembly. Measure, or

mark a piece of scrap paper, the adjustment length of the Tensioner Bolt

(C1) and nut (C2).

4.

Using a 10 mm wrench, loosen and remove the outer nut (C2) so the

Tension Bolt (C1) can be released from the Tensioner Bracket (D).

5.

Using a 6mm hex key and 13mm wrench, loosen the Tensioner

Assembly Hardware (E) that attaches the Tensioner Assembly (C) to the

Frame upright (F).

Note:

Use the hex key to hold the bolt in place on the outside and

turn the nut from the inside.

C

A

B

C1

C2

E

D

F