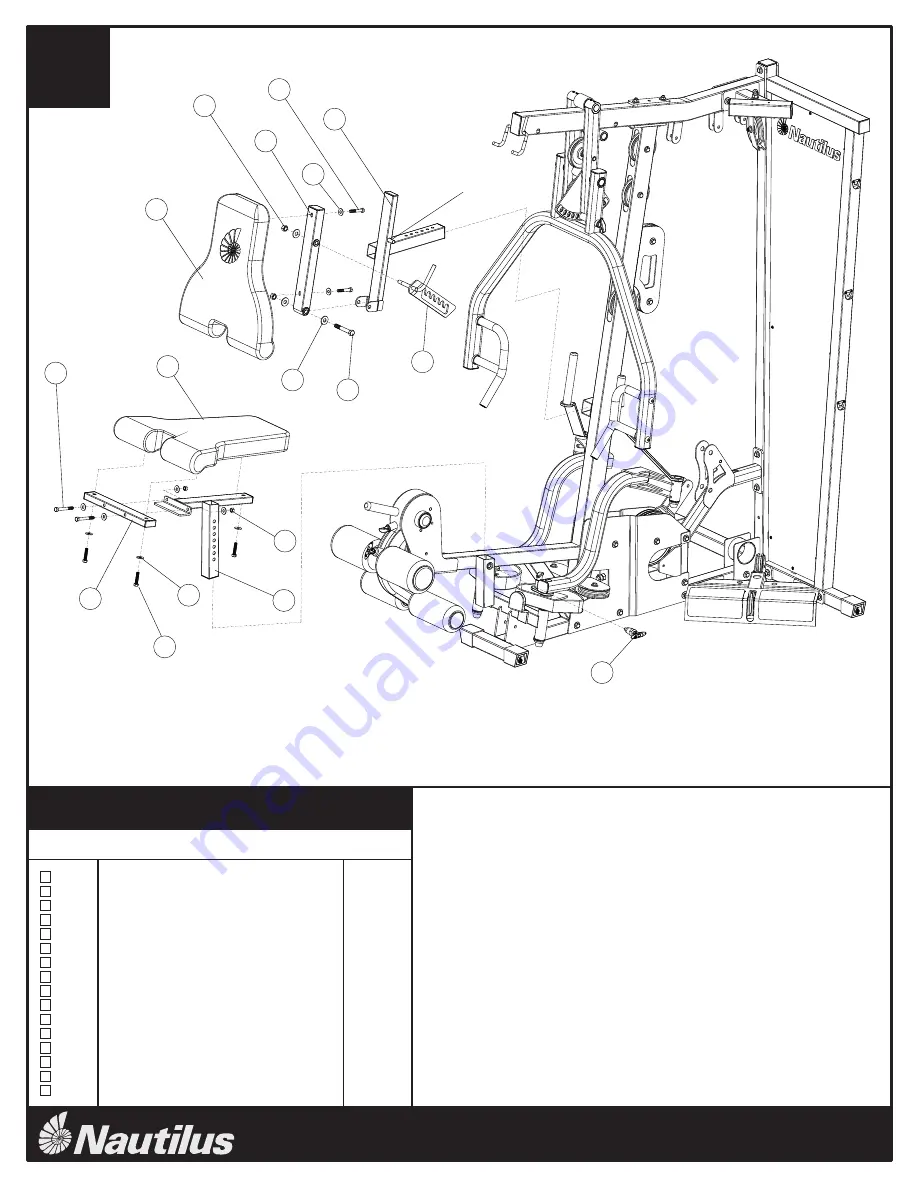

34

26

24

25

23

22

27

28

66 1 3/4"L

62 3"L

77

74

64 2 1/4"L

74

76

57

73

3 1/4"L

Seat Adjuster

Seat Cross Tube

Back Pad Tube

Back Pad Adjuster

Back Pad Adjustment Plate

Seat Pad

Back Pad

T Handle Pop Pin

Hex Bolt 1/2" x 3 1/4"L

Hex Bolt 3/8" x 3"L

Hex Bolt 3/8" x 2 1/4"L

Hex Bolt 3/8" x 1 3/4"L

1/2" Flat Washer Narrow

3/8" Flat Washer

1/2" Lock Nut

3/8" Lock Nut

A.

Attach Seat Cross Tube (23) to Seat Adjuster (22) using hardware shown.

Tighten hardware securely.

B.

Attach Seat Pad (27) to Seat Cross Tube (23) and Seat Adjuster (22) using

hardware shown. Tighten hardware secruely.

C.

Attach T Handle Pop Pin (34) to the Leg Extension Assembly with adjustable

wrench.

D.

Install Seat Adjuster (22) in Leg Extension Assembly in the slot shown. Use the

Pop Pin (34) to adjust height. NOTE: Pop Pin is threaded so that the seat can

be locked in place.

E.

Attach Back Pad Tube (24) to Back Pad (28) using hardware shown. Tighten

hardware securely.

TM

NS-600

10

Step #5 Materials:

step

5

#

Description

Qty.

1

1

1

1

1

1

1

1

1

2

2

3

3

9

2

2

22

23

24

25

26

27

28

34

57

62

64

66

73

74

76

77

F.

Attach Back Pad Tube (24) to Back Pad Adjuster (25) using hardware shown.

Tighten hardware securely making sure the Back Pad Tube (24) can rotate freely.

G.

Attach Back Pad Adjustment Plate (26) to Back Pad Tube (24) using hardware

shown. Make sure that the Back Pad Adjustment Pin rests inside the slot of the

Back Pad Adjustment Plate (26). Tighten hardware securely making sure the Back

Pad Adjustment Plate (26) can rotate freely.

H.

Install Back Pad Adjuster (25) in Front Upright in the slot shown.

BACK PAD

ADJUSTMENT PIN