57

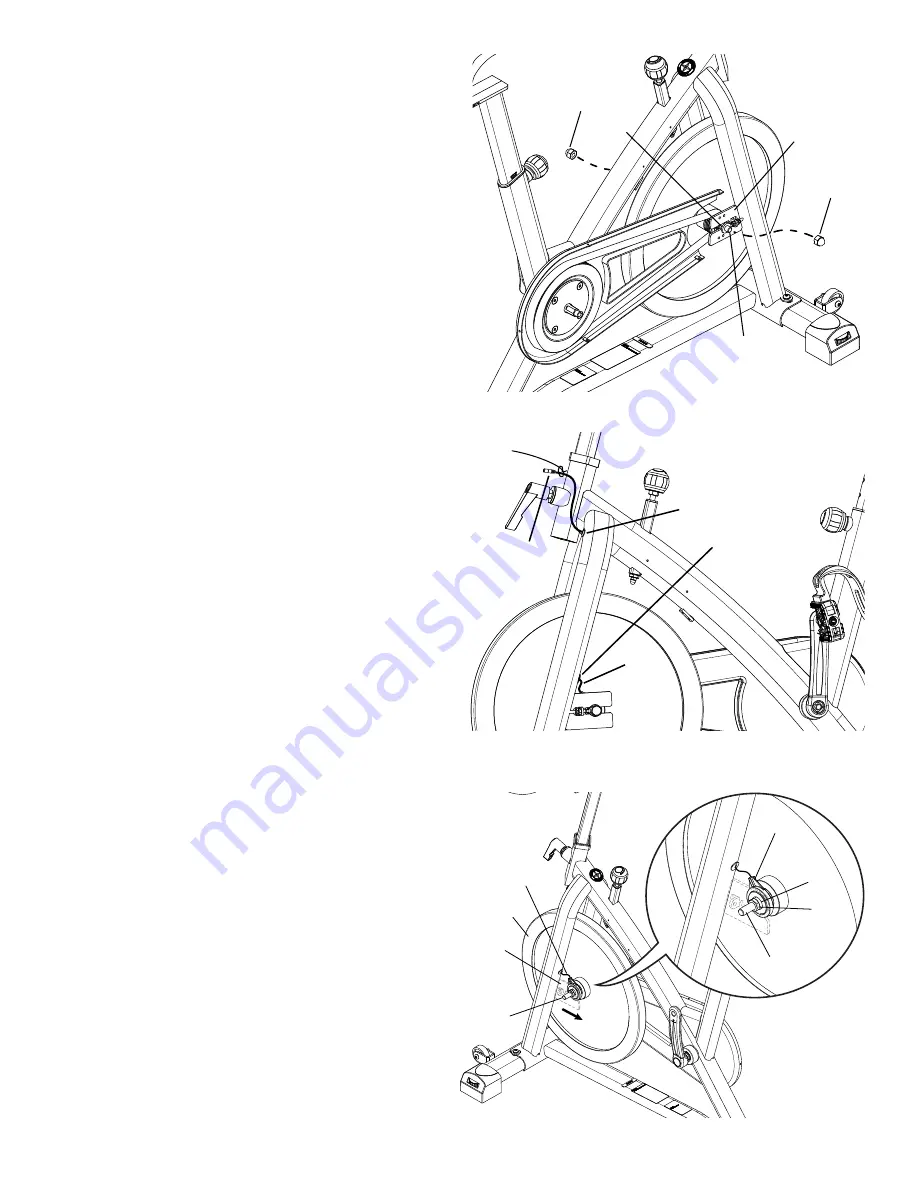

11. To loosen the Flywheel hardware, use a 15 mm crescent wrench to

hold the Axle Nut (I) on one side steady and loosen the Axle Nut on the

opposite side with a 15 mm socket and wrench. Remove the Axle Nuts

from the Flywheel axle (J). Set the hardware safely aside for reassembly.

12. Using a 10mm wrench, loosen and remove the Flywheel Retainer

nut (K1) that is closest to the Frame. Remove the Tensioner eyebolt (G)

and Nut (K2) from the Flywheel axle (J) and Tensioner support (H1). Set

the Tensioner hardware aside for reassembly.

NOTICE:

It may be necessary to move the Flywheel (L). This step

may require two people.

13. Remove the rubber grommets from the top opening (R1) in the left

Frame upright and the lower opening (R2) near the Speed Sensor. Set the

grommets safely aside for reassembly.

NOTICE:

Make sure the Speed Sensor cable is disconnected from

the Console cable.

14. Tie the length of string to the end (N1) of the Speed Sensor cable

at the top opening (R1) in the left Frame upright. Hold the other end of

the Speed Sensor cable (N2) and carefully pull it out of the lower opening

(R2) so that the string extends through the upright. Untie the string from

the old Speed Sensor cable.

NOTICE:

This step may require two people.

15.

&DUHIXOO\PRYHWKH)O\ZKHHO/WRWKHRSHQLQJLQWKHÀ\ZKHHO

brackets (H) and remove the Flywheel from the bracket. Remove the

thin Nut (M) from the left end of the axle (J) and set it safely aside for

reassembly.

NOTICE:

This step may require two people.

16. Carefully remove the Speed Sensor (N) and Spacer (O) from the

axle (J). Set the old Speed Sensor safely aside.

NOTICE:

This step may require two people.

17.

+ROGWKH)O\ZKHHO/QHDUWKHÀ\ZKHHOEDQGSXWWKHQHZ

Speed Sensor (N) and the Spacer (O) in position on the axle (J). Reinstall

the thin Nut (M) on the axle.

NOTICE:

This step may require two people. Do not crimp any

cables

I

G

+

J

I

R2

R1

N2

N1

M

O

N

J

J

N

+

L