4.1.2 Driveline Phasing

Heavy-duty U-joints have a unique characteristic. Because they are always operating at

an angle, they do not transmit constant torque or turn at a uniform speed during their

360-degree rotation (

Figure 8-48)

.

Figure 8-48 - A driveshaft will increase and decrease speed once each

revolution.

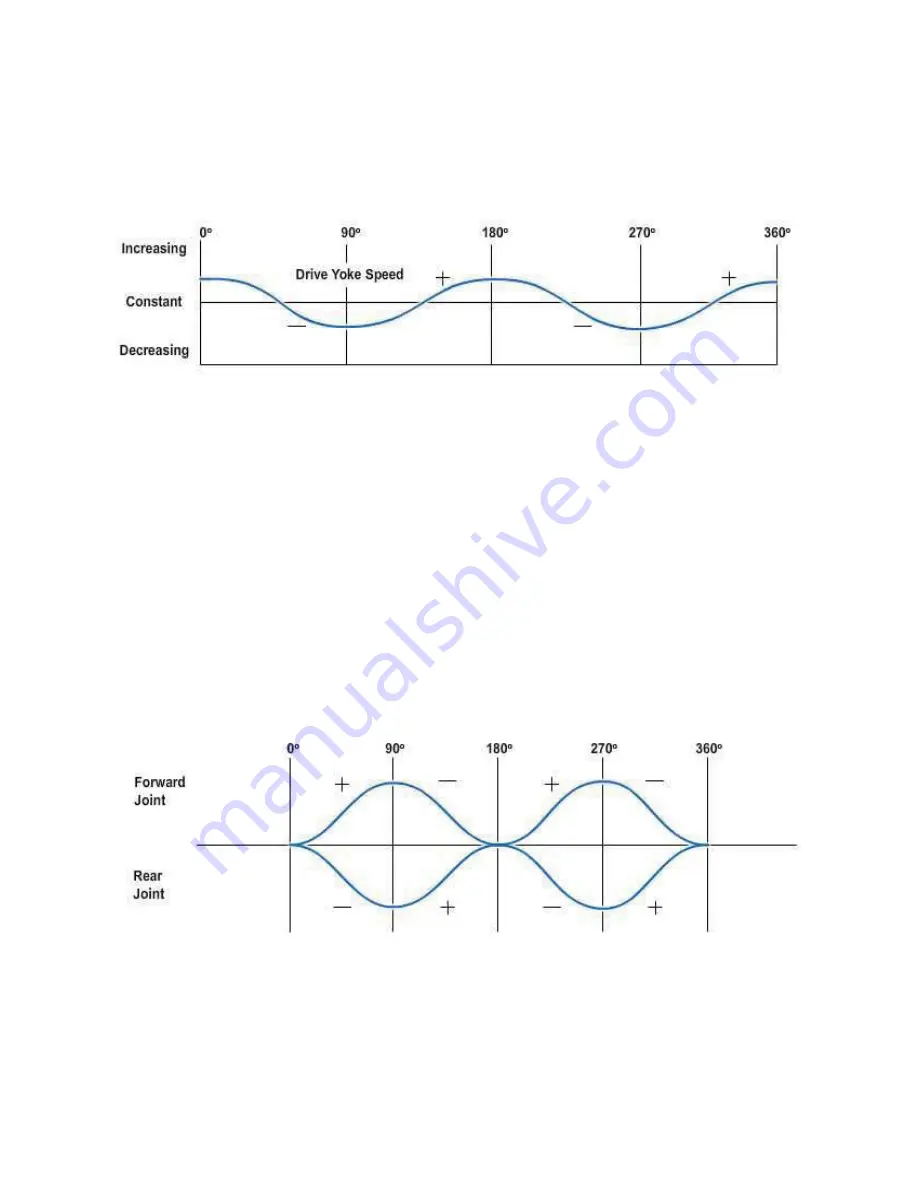

With the drive yoke turning at a constant rpm, a driveshaft increases and decreases

speed once each revolution. To counterbalance this fluctuation above and below mean

(average) driveshaft speed, the U-joints must be positioned in-phase with each other as

demonstrated in

Figure 8-49

. An out-of-phase condition produces an effect similar to

what occurs when two children are turning a rope, and the rope is snapped on one side;

by contrast, if the rope is snapped at both ends at the same time, the resulting waves

through the rope cancel each other, and neither child feels the reaction of the wave the

snap causes.

Figure 8-49 - Two universal joints in-phase will cancel out the speed

fluctuations in the driveshaft.

When in phase, the slip yoke lugs (ears) and welded yoke at the opposite end should be

perfectly in line as illustrated in

Figure 8-50

. If a driveshaft is assembled one spline out,

the driveshaft is out of phase and the result can be a significant vibration. There should

be opposing alignment arrows stamped on the slip yoke and on the tube shaft so you

NAVEDTRA 14050A

8-53